Circular feather cleaning device

A cleaning device and feather technology, applied in the field of feather processing equipment, can solve the problems of increased cost, damaged color, and low cleaning quality, and achieve the effects of saving costs, protecting against damage, and improving cleaning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make those skilled in the art better understand the technical scheme of the present invention, the present invention will be further described below:

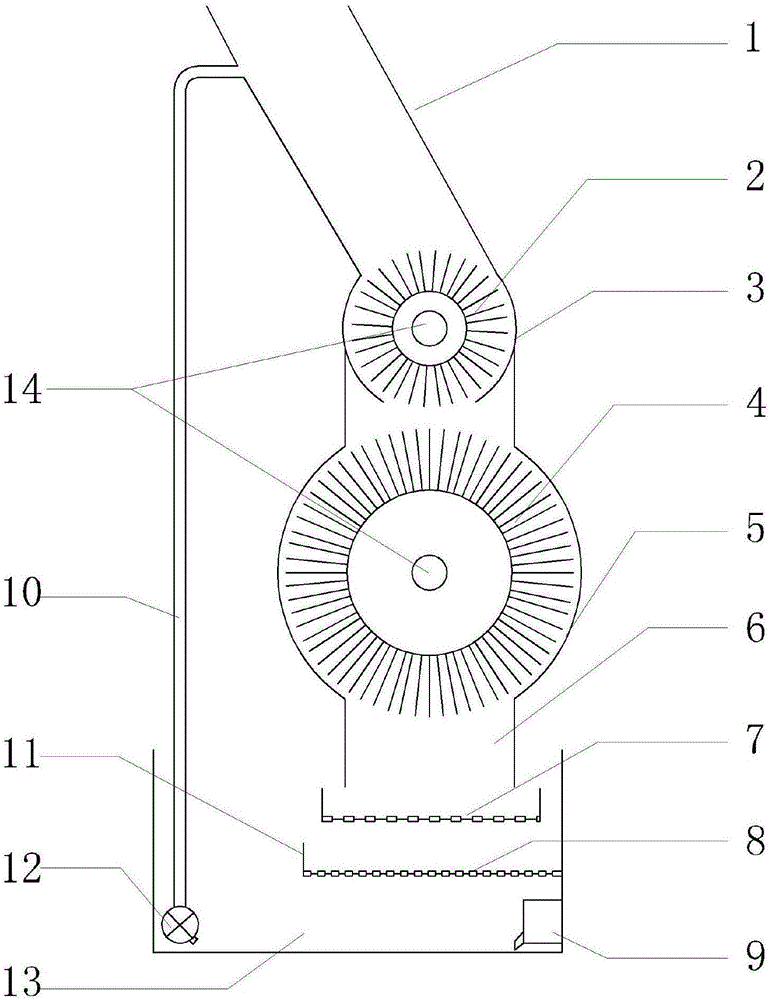

[0016] A feather circulation cleaning device, comprising a water tank 13, a water pump 12, a feeding pipe 1, a first cleaning chamber 3, a second cleaning chamber 5, a first round brush 2, a second round brush 4, a wool filter 7, and a water filter 8. The first cleaning chamber 3 and the second cleaning chamber 5 are both flat and cylindrical, wherein the top of the first cleaning chamber 3 is connected to the feeding pipe 1 which is inclined upward, and the inside is connected to the first round brush 2 by rotation, and the bottom is connected Connect the second cleaning bin 5; the inside of the second cleaning bin 5 is rotated to connect the second round brush 4, the bottom of which is provided with a feeding port 6, and a water tank 13 is arranged below the feeding port 6; the water tank 13 and the feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com