Drive device of a combing machine

A driving device and combing machine technology, which is applied in the direction of combing machines, mechanical equipment, textiles and papermaking, etc., can solve problems such as shortening service life, and achieve the effect of increasing efficiency and optimal transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

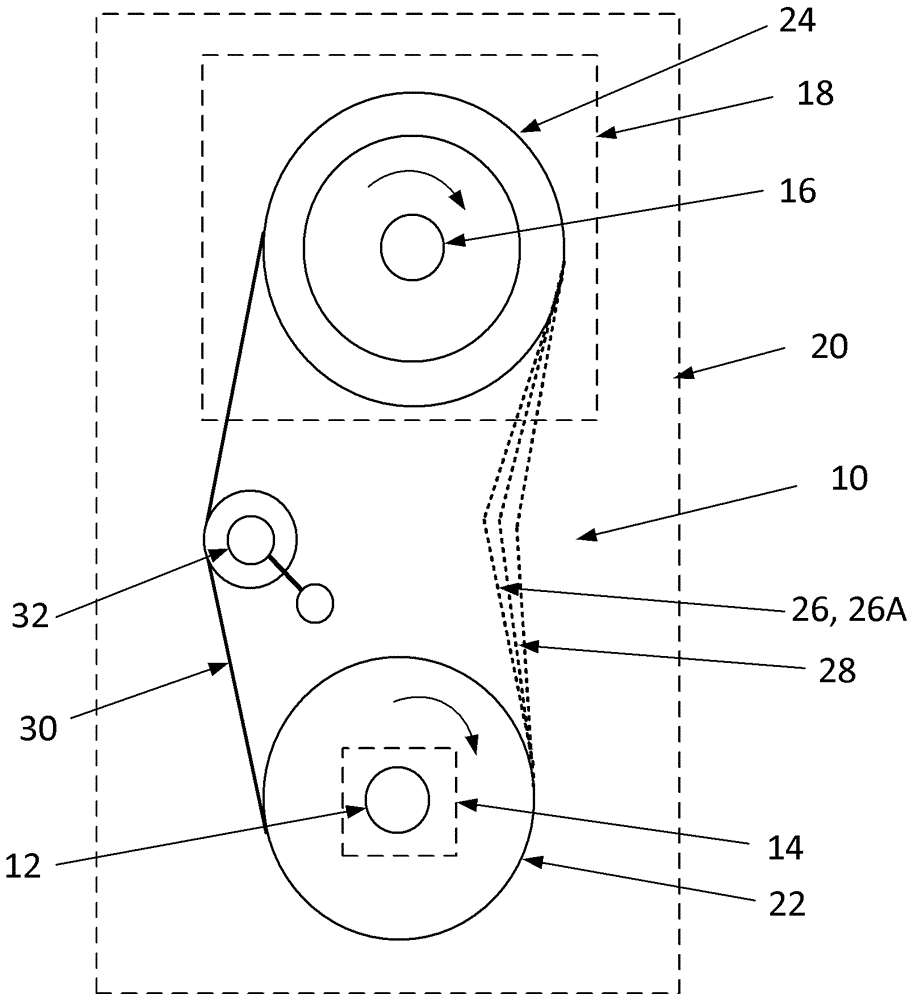

[0026] figure 1 A drive 10 of a known prior art combing machine 20 is shown purely schematically between an electric motor 14 comprising an output shaft 12 and a gearbox 18 comprising an input shaft 16 . To improve the illustration of the interaction of the drive 10 with the electric motor 14, the gearbox unit 18 and the comber 20, these components are described in figure 1 shown in dotted line. The working elements (not shown) of the comber 20 are driven by the gearbox unit 18 .

[0027] The working elements of known combing machines are considered to be, for example, working elements for driving the nipper unit, and / or working elements for driving the detaching rollers, and / or working elements for driving a circular comb.

[0028] A motor pulley 22 is provided on the output shaft 12 of the electric motor 14 , while a gearbox pulley 24 is provided on the input shaft 16 of the gearbox unit 18 . The drive means 26 interacts with the motor pulley 22 and the gearbox pulley 24 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| inertia | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com