Siro-spinning rotary separation type press bar spacer block

A technology of rotary separation and pressure rod, which is applied in the field of textile processing, can solve the problems of inapplicability, and achieve the effect of reducing yarn hairiness, reducing loss, and reducing single fiber breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

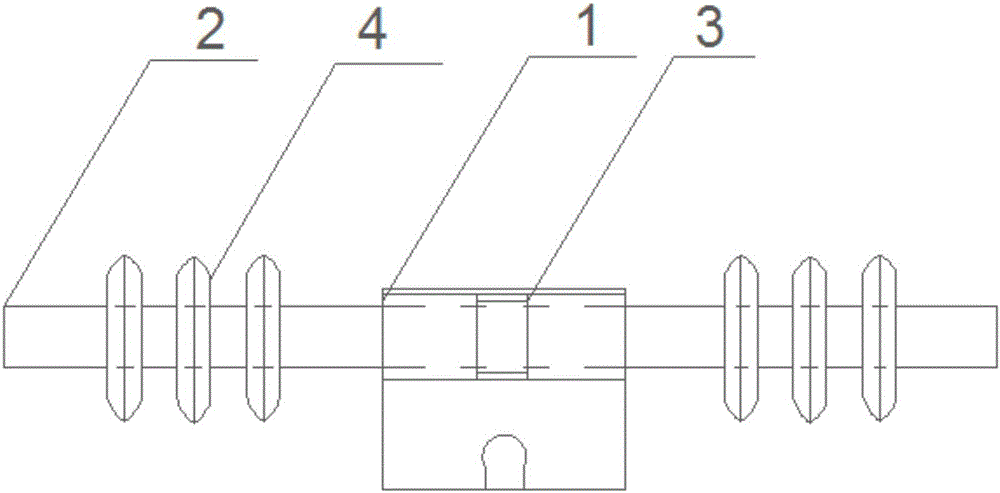

[0014] Below in conjunction with accompanying drawing, the present invention is described in further detail, see accompanying drawing.

[0015] A siro spinning rotary separation pressure rod spacer, the rotary separation pressure rod spacer is composed of a spacer 1, a pressure rod 2, a bearing 3, and a guide wheel 4, and the pressure rod 2 is a whole piece in the form of a smooth cylinder Body shape, the length range of the pressure bar 2 is as wide as the width of the front top roller, the pressure bar 2 is fixedly installed in the spacer 1 through the bearing 3, the bearing 3 is located at the center of the length direction of the spacer 1, and the pressure bar 2 is in the spacer 1 The spacer 1 rotates freely, and the bearing 3 can effectively limit the left and right swing of the pressure bar 2 in the spacer 1, effectively preventing the instability caused by the left and right swing of the pressure bar 2 from affecting the yarn quality. Longitudinal strengthening of the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com