Ultra-low liquor ratio rope dyeing small sample tank

An ultra-low bath, rope-like technology, applied in the field of dye vats, which can solve the problems of different machine sizes and capacities, full space occupied by fabric accumulation, negative effects, etc., to increase the success rate, avoid separation of cloth and water, and ensure normal operation. running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

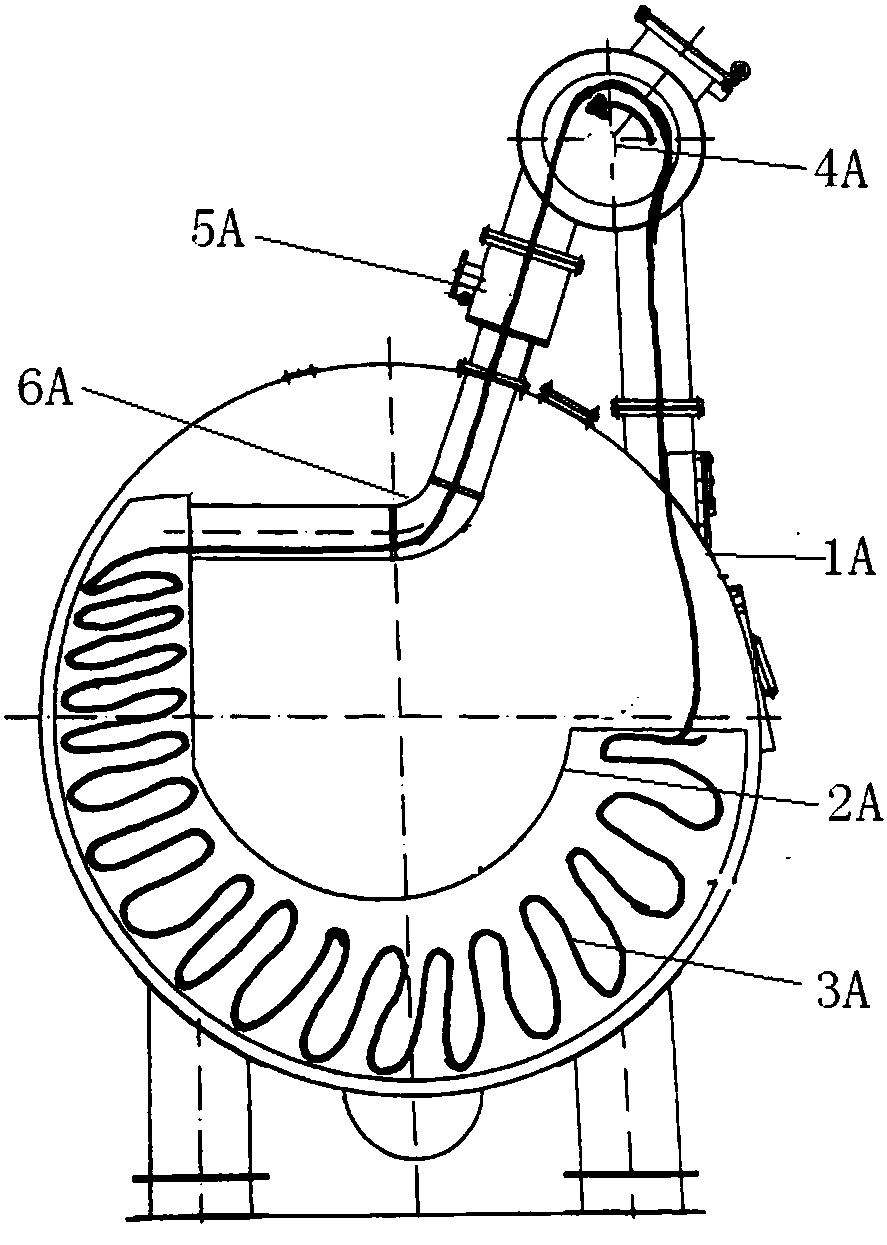

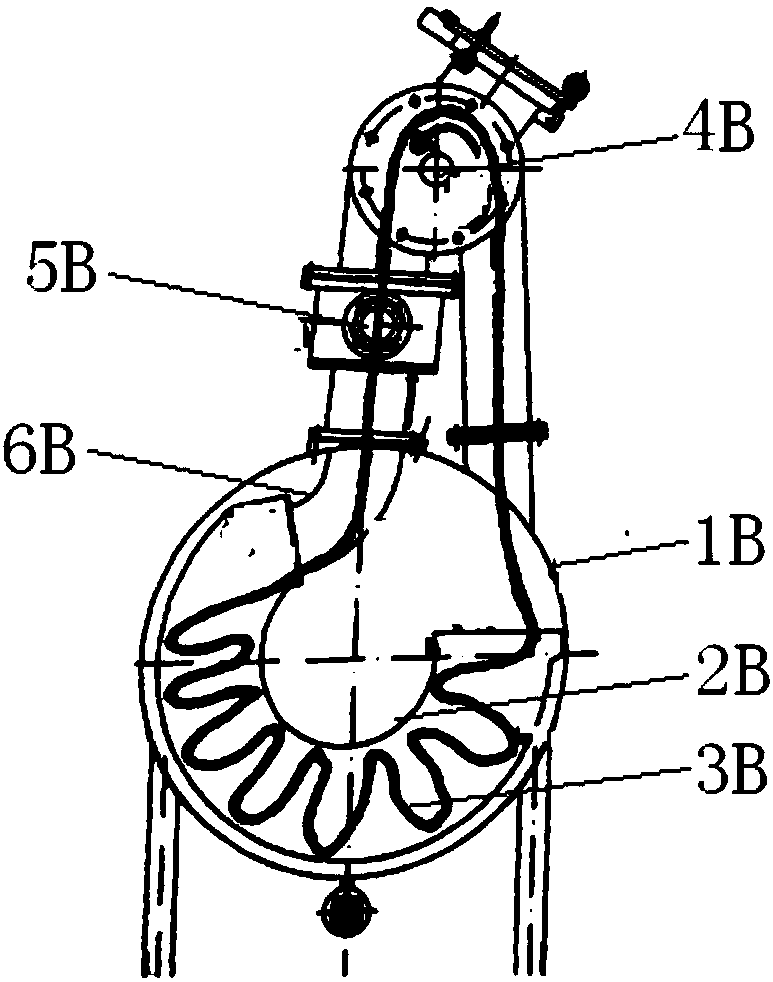

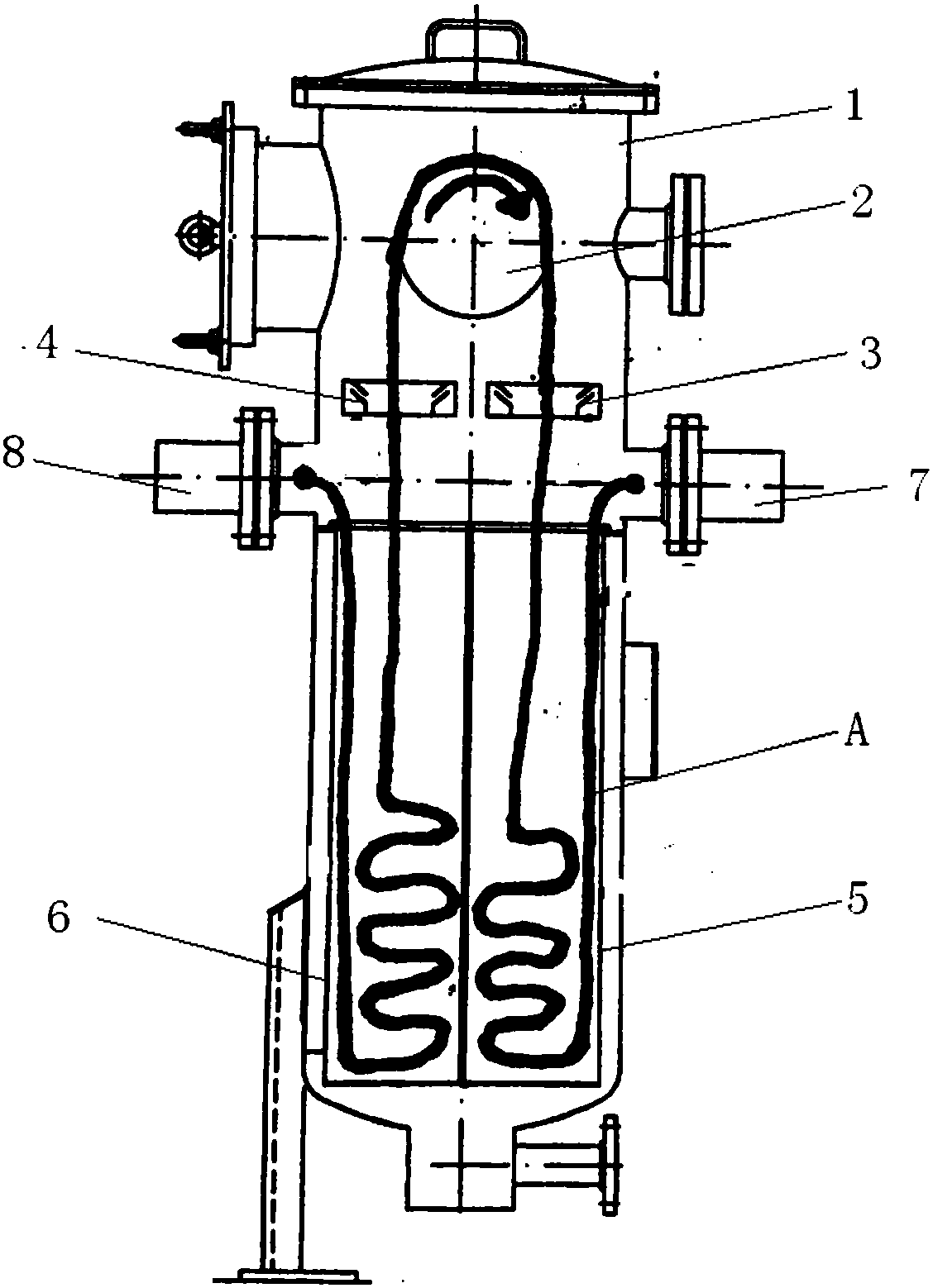

[0020] Such as image 3 As shown, the present invention mainly includes a vertical cylinder body 1, and the lower part of the vertical cylinder body 1 is provided with a U-shaped first cloth groove 5 and a second cloth groove 6 side by side.

[0021] The upper part of the vertical cylinder body 1 is provided with a cloth lifting wheel 2, and the bottom of the cloth lifting wheel 2 is provided with a first nozzle 3 and a second nozzle 4, and the first nozzle 3 and the second nozzle 4 are arranged symmetrically. When dyeing, the cloth-lifting wheel 2 can rotate bidirectionally, and the first nozzle 3 and the second nozzle 4 are opened and closed in turn according to the operation of the cloth-lifting wheel. When the cloth lifting wheel 2 rotates clockwise, the first nozzle 3 is opened; when the cloth lifting wheel 2 rotates counterclockwise, the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com