Lifting and pulling mechanism of drain valve

A technology of lifting mechanism and drain valve, which is applied in the field of sanitary ware, can solve problems such as the limitation of lifting position, the inability to shorten the lateral distance at will, and the difficulty in flexibly selecting the lifting position of the riser 3', so as to reduce the opening force value, Effect of Reducing Torsional Moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

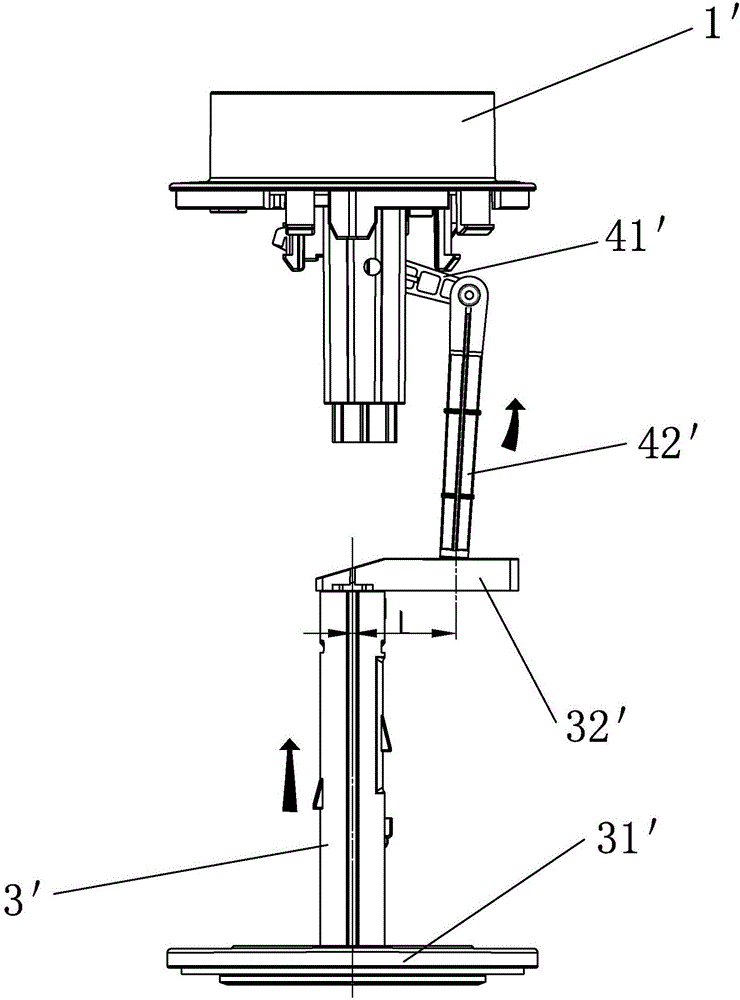

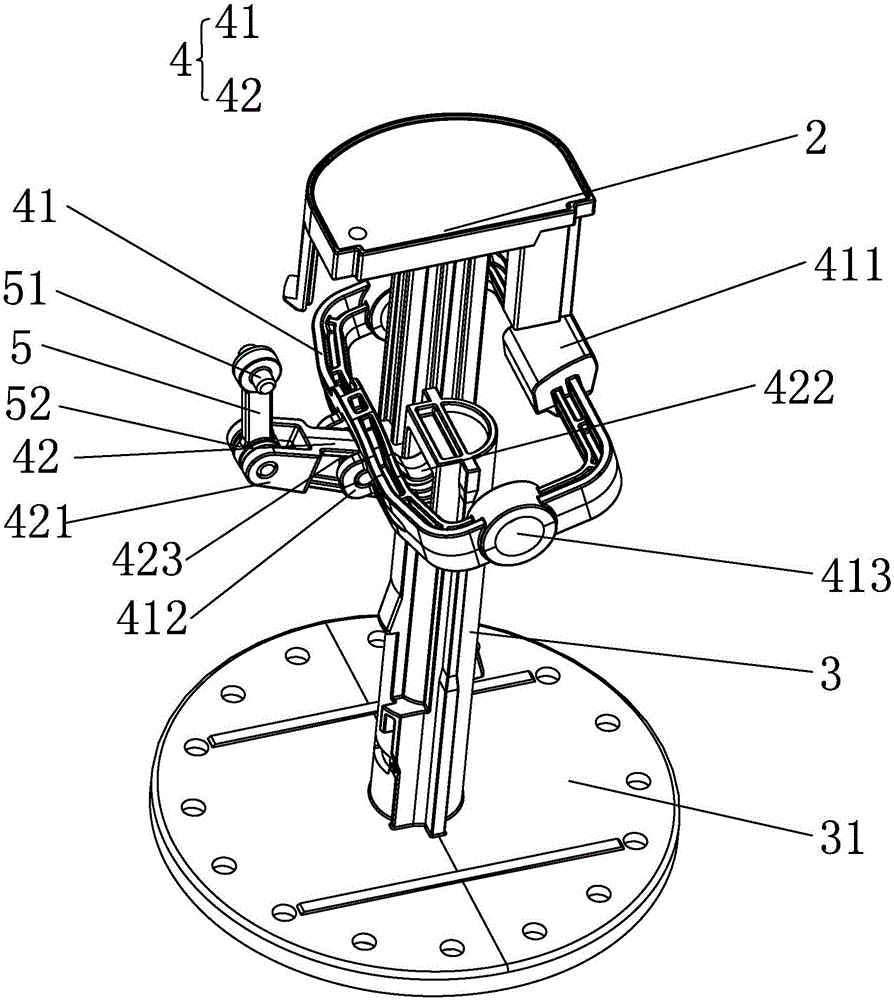

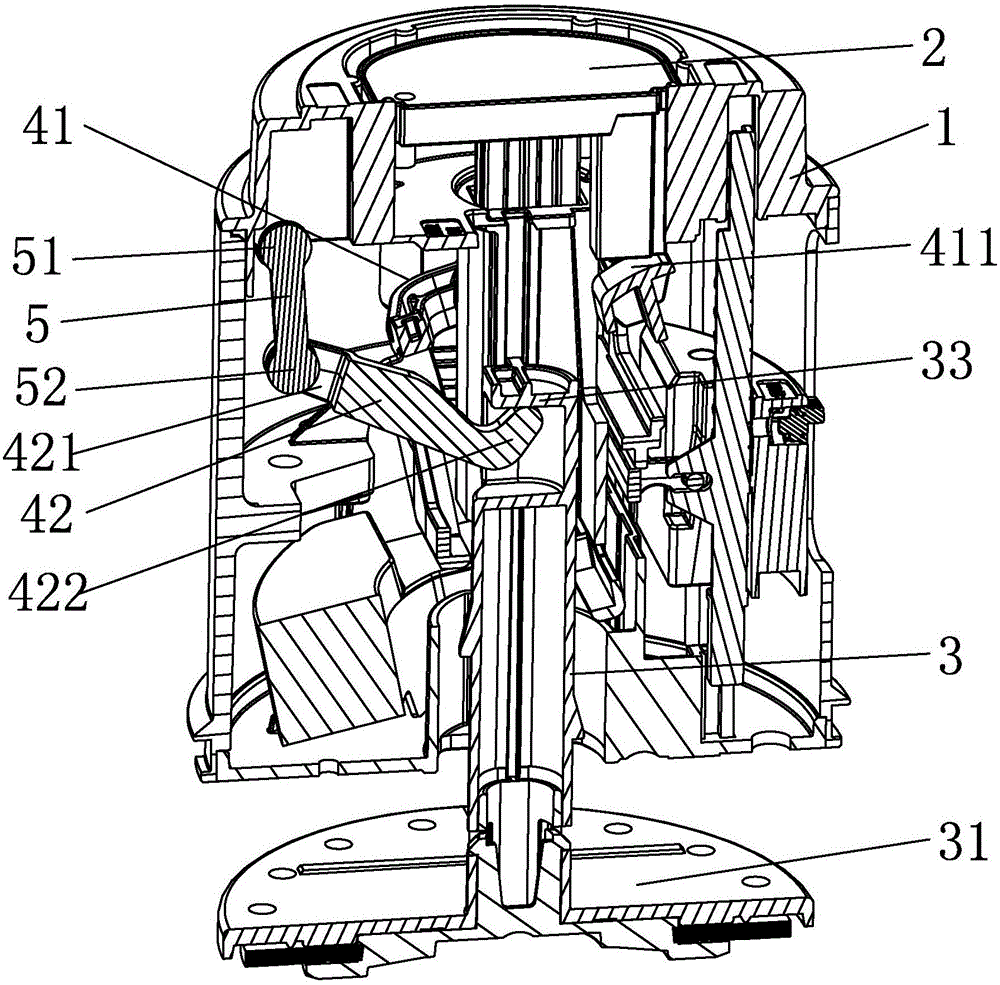

[0027] Such as Figure 2 to Figure 4 , Figure 2 to Figure 4 A lifting mechanism 4 of a drain valve according to the first embodiment of the present invention is shown. The drain valve includes a valve body 1, an activation element 2, a riser 3 and a lifting mechanism 4. The lifting mechanism 4 is arranged on the valve of the drain valve. In the body 1, it is used to drive and cooperate with the actuating element 2 of the drain valve to pull the lift pipe 3 installed in the valve body 1. The actuating element 2 in this embodiment is a button, and the button is movably installed on the top of the valve body 1 In the provided button seat, the bottom end of the riser 3 is fixedly connected with a valve disc 31 that matches the drain port of the drain valve, and the starting element 2 lifts the riser 3 upwards through the lifting mechanism 4 to drive the valve disc 31 to move upwards. And open the drain port of the drain valve to realize draining. The pulling mechanism 4 at leas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com