Filling box with upper and lower metal nets

A metal mesh and filling box technology, which is applied to building components, floors, buildings, etc., can solve the problems of poor integrity of filling materials, large buoyancy of filling materials, and small vertical stiffness, and achieve good economy and applicability. Large span , the effect of large horizontal and vertical stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is realized in the following manner:

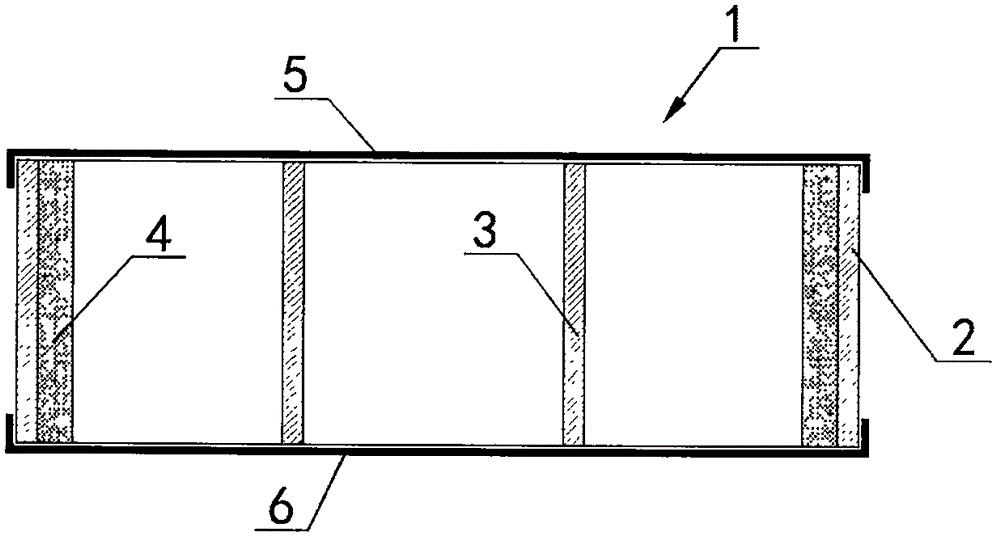

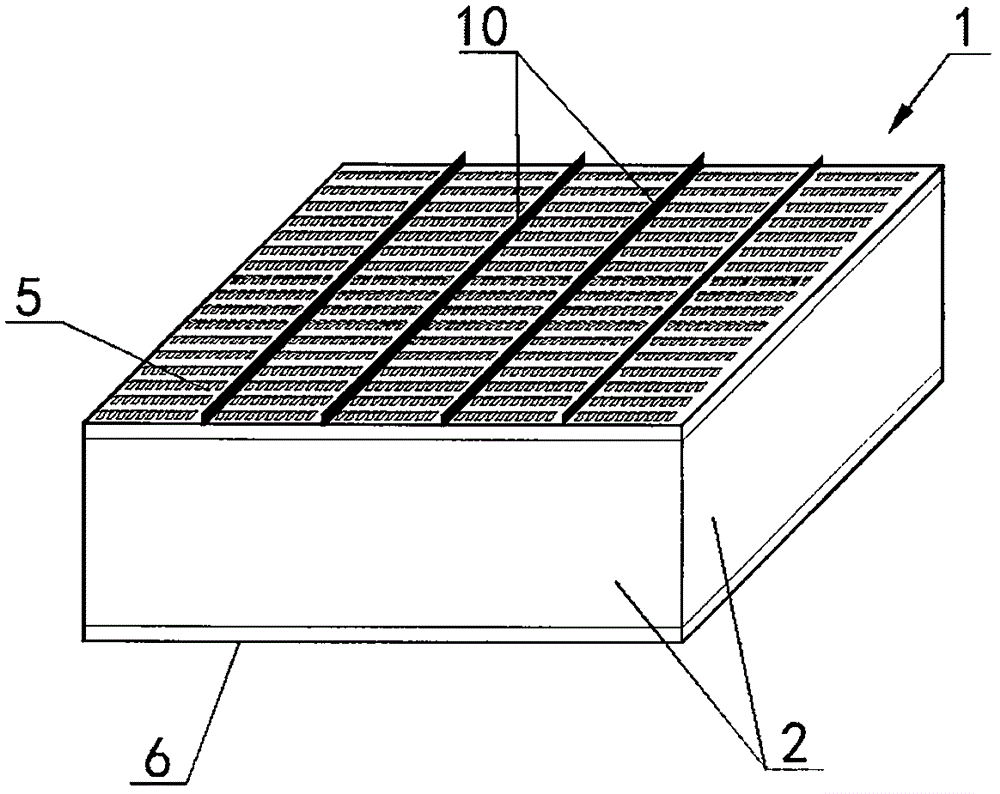

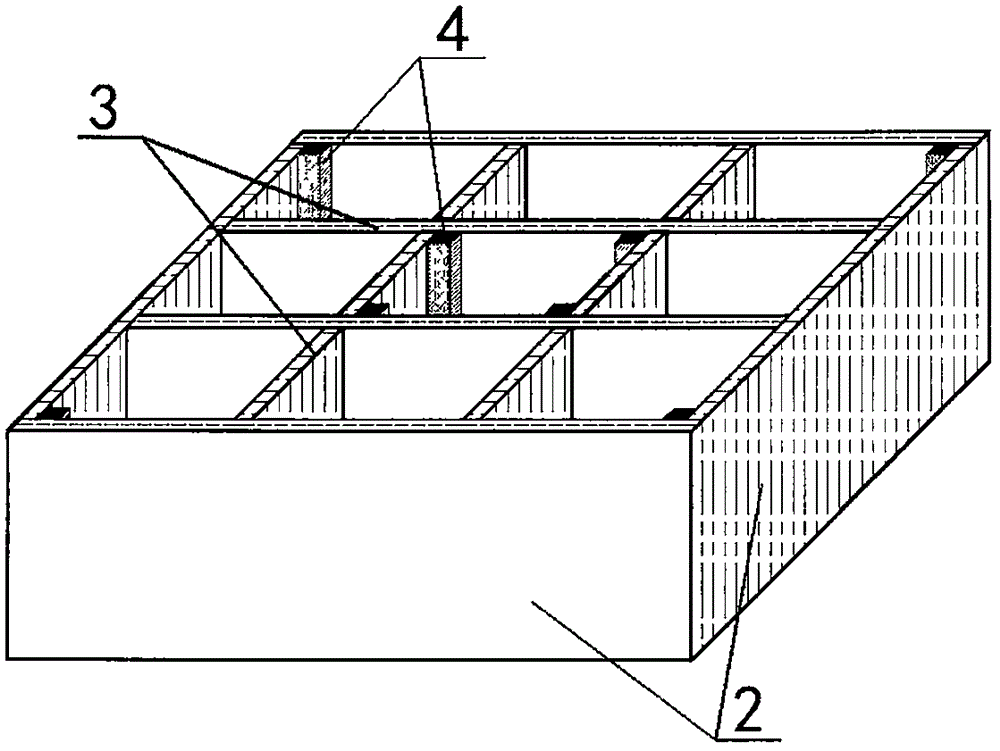

[0035] exist Figure 1-Figure 3 In the shown embodiment, a filling box with an upper and lower metal mesh, the filling box (1) includes a frame panel (2), a stiffened inner panel (3), a connecting reinforcing column (4), an upper metal mesh (5), Lower the metal mesh (6), fix the frame board (2) on the connecting reinforcement column (4) by means of nail anchoring, iron wire binding or glue pasting, and the four frame boards (2) connected end to end form a rectangle Plane, there is at least one or more stiffened inner panels (3) in each direction in the rectangular plane, the stiffened inner panels (3) in different directions are orthogonal to each other, and the frame panels (2) and stiffened inner panels (3) together constitute A box-shaped structure that is open up and down. The upper and lower metal meshes (5) and lower metal meshes (6) are respectively installed on the top and bottom of the box-shaped str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com