A secondary lining trolley for large-span variable-section tunnels and its construction method

A technology of secondary lining and construction method, applied in tunnel lining, tunnel, wellbore lining, etc., can solve the problems of large consumption of manpower and material resources, long installation time, high safety risk, and achieve labor saving, easy duplication and simple production process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

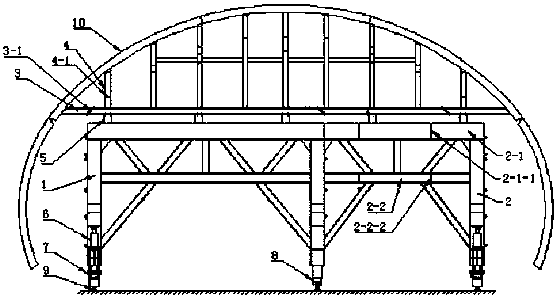

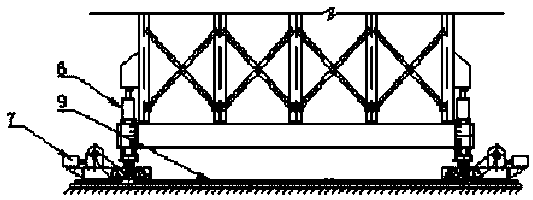

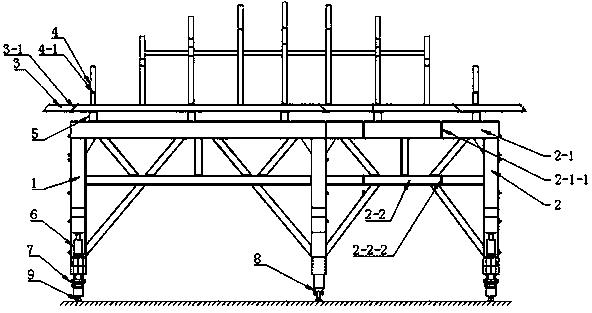

[0026] Embodiment 1: as Figure 1-Figure 6 As shown, a secondary lining trolley for a large-span variable-section tunnel includes a main gantry 1, a secondary gantry 2, a formwork beam 3, and a formwork column 4. The secondary gantry 2 is installed next to the main gantry 2, and The frame 2 forms a horizontal E-shaped structure, the opening direction of the horizontal E-shaped structure is downward, and its top is connected to the formwork beam 3 through the upper longitudinal beam 5, and the formwork column 4 is set on the formwork beam 3, and the upper end of the formwork column 4 is against the lining section The template 10 at the top, the main gantry 1 and the secondary gantry 2 are placed on three steel rails 9, a breaking node 1 is set on the beam 2-1 of the secondary gantry 2, and a detachable connecting plate 2-2 is set at the breaking node. 1-1, formwork column 4 and formwork beam 3 respectively set breaking node 2 and breaking node 3, respectively set detachable con...

Embodiment 2

[0029] Embodiment 2: A construction method for the secondary lining trolley of a large-span variable-section tunnel. The implementation steps of the method are as follows:

[0030] (1) Based on the design of the largest section, analyze the structural dimensions of other sections, and set the double gantry structure of the main gantry 1 and the secondary gantry 2 on the secondary lining trolley. The beam 2-1 of the gantry 2, the formwork column 4 and the formwork beam 3 are respectively provided with breaking nodes, and the first connecting plate 2-1-1, the second connecting plate 4-1 and the third connecting plate 3-1 are arranged at the breaking nodes;

[0031] (2) When the lining section changes, remove all formwork 10 on the top of the lining section;

[0032] (3) Remove the redundant parts of formwork column 4 and formwork beam 3 corresponding to the breaking node, and adjust the connection positions of formwork column 4 and formwork beam 3, formwork beam 3 and upper long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com