Supporting mounting rack

A mounting frame and mounting plate technology, applied in the field of machinery, can solve the problems of reduced motor resource utilization, waste of resources and space, and large space occupation, and achieve the effects of saving storage, flexible and convenient use, and avoiding waste of resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

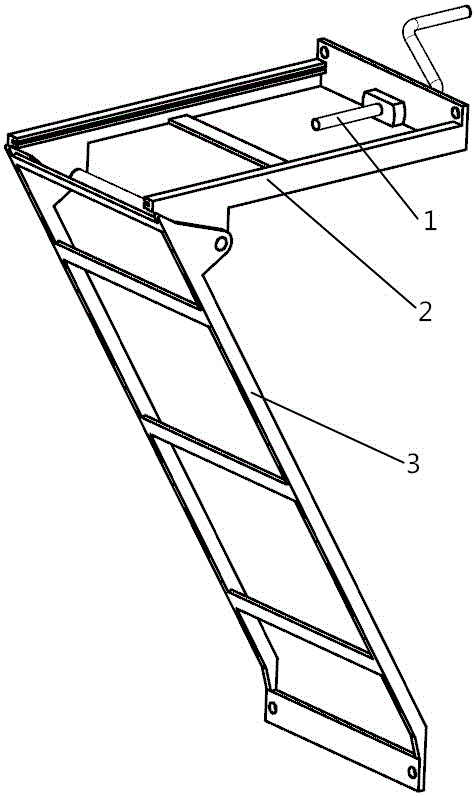

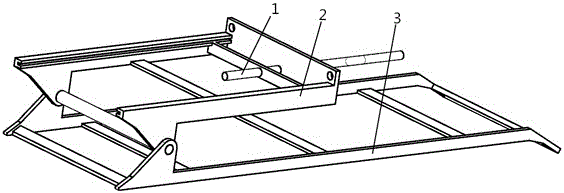

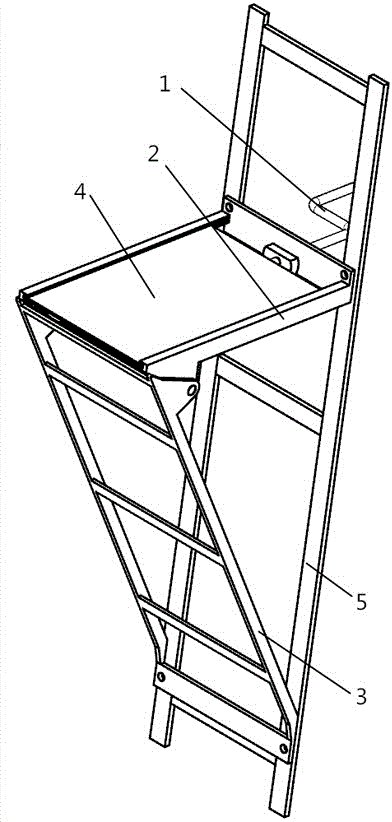

[0028] see Figure 1 to Figure 6 , the supporting mounting frame of the present invention includes a mounting plate 4, a horizontal frame 2 for fixing the mounting plate 4, an inclined frame 3 for supporting the horizontal frame 2, and a curved bar 1 for locking the mounting plate 4; the horizontal frame 2 One end is connected with one end of the inclined frame 3, and the other end of the horizontal frame 2 and the inclined frame 3 are connected with the rice mill frame 5; the horizontal frame 2 includes a horizontal frame side bar I21a, a horizontal frame side bar II21b, and a horizontal frame end plate 24, There are concave rails 20 inside the side bars of the two horizontal frames, and the two sides of the mounting plate 4 are slidingly assembled in the concave rails 20; the side of the horizontal frame end plate 24 of the horizontal frame 2 is provided with a screw-in device for the curved rod 1, and the curved rod 1 is formed by a The Z-shaped three-segment curved rod for...

Embodiment 2

[0038] see Figure 7 , the screw-in device is composed of a horizontal frame end plate 24 and a horizontal frame baffle plate 28. The frame baffle plate 28 is respectively provided with a through hole I27 and a through hole II29 on the same axis, and at least one of the two through holes is a threaded hole matched with the thread of the curved rod 1, otherwise it is consistent with the embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com