A field straw burning grain drying device

A drying device and straw technology, applied in the directions of drying, drying machine, heating device, etc., can solve problems such as troublesome, large coal power consumption, etc., achieve convenient use, save coal power consumption, and ensure sufficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

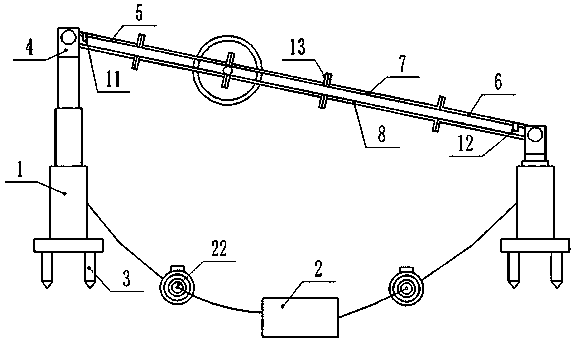

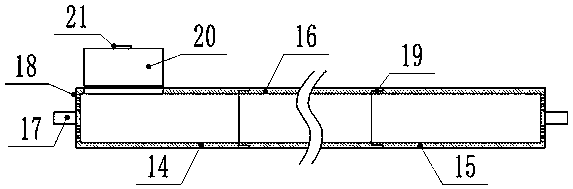

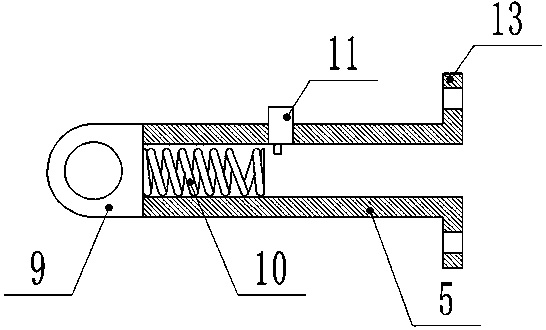

[0014] see Figure 1-4 , a field straw burning grain drying device, comprising an electric telescopic rod 1, a sliding frame, a drying cylinder and a control box 2, the electric telescopic rod 1 is provided with four, placed in the four corners of the field when in use, electric The lower end of the telescopic rod 1 is threadedly connected with a ground bolt 3. When it is convenient to drill the ground, the stability is improved through the ground bolt 3. If it is inconvenient to drill the ground, the electric telescopic rod 1 can be disassembled to facilitate the placement of the electric telescopic rod 1. The upper end of the electric telescopic rod 1 is fixedly connected with a The turret 4 is rotatably connected to the turret 4, and the drying cylinder is rotatably connected to the turret; the sled is composed of a head frame 5, a tail frame 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com