Rock sample coring device

A technology for rock samples and coring devices, applied in sampling devices and other directions, can solve the problems of natural gas influence, large natural gas loss, and long time to obtain rock samples, and achieves optimistic application prospects, accurate natural gas content, and convenient and large-scale testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing.

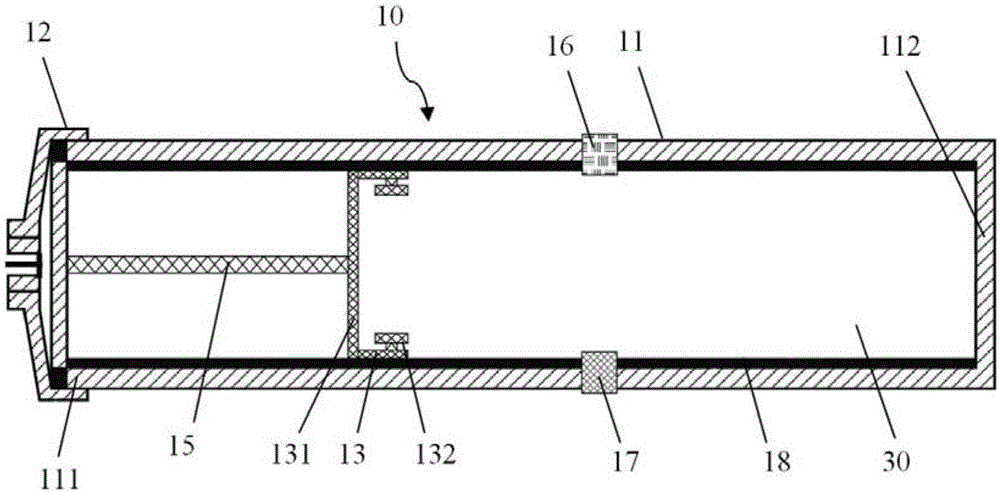

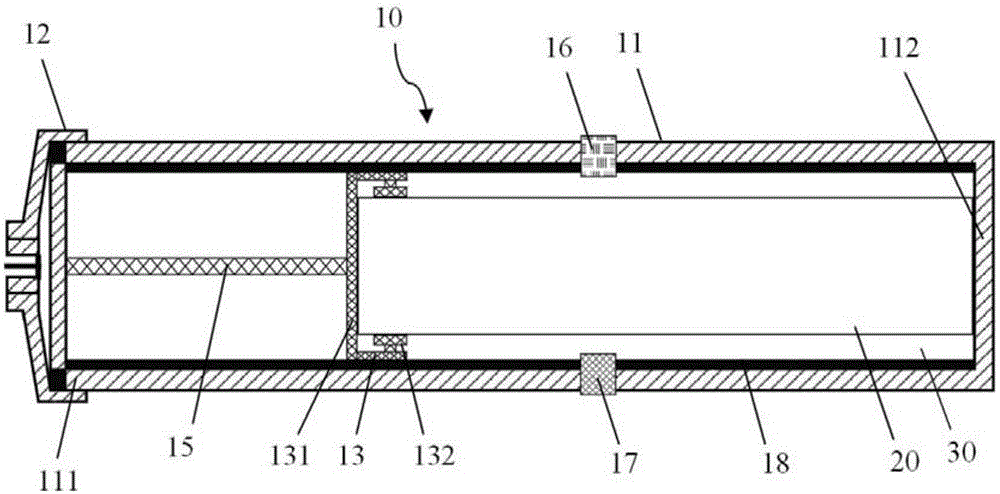

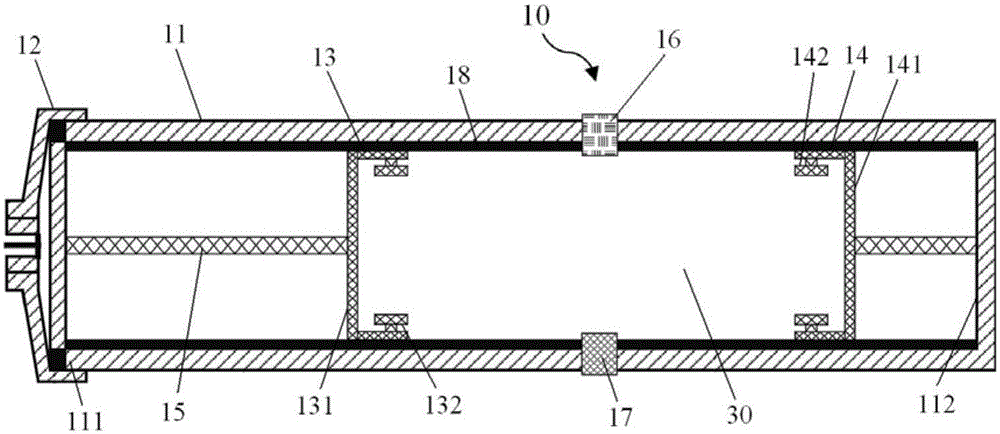

[0025] figure 1 The overall structure of the rock sample coring device 10 (hereinafter referred to as the device 10 ) of the present invention is schematically shown. The device 10 includes a housing for housing a rock sample 20 . The containing cylinder includes a cylinder body 11 and a cylinder cover 12 connected with the cylinder body 11 . The first end 111 of the cylinder body 11 is open, the second end 112 is closed, and the cylinder cover 12 is arranged at the first end 111 to surround the rock sample 20 together with the cylinder body 11, providing the rock sample 20 with a space suitable for coring. Sample holding chamber 30 .

[0026] Preferably, the cylinder cover is connected to the cylinder body in a sealed manner, so that the pressure in the containing cylinder can be kept constant, and then the pressure in the containing cylinder can be close to the pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com