Mini-type high-temperature and high-pressure test system and method

A high-temperature, high-pressure, test system technology, applied in the direction of electronic circuit testing, measuring devices, instruments, etc., to achieve the effect of saving human resources and high testing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings:

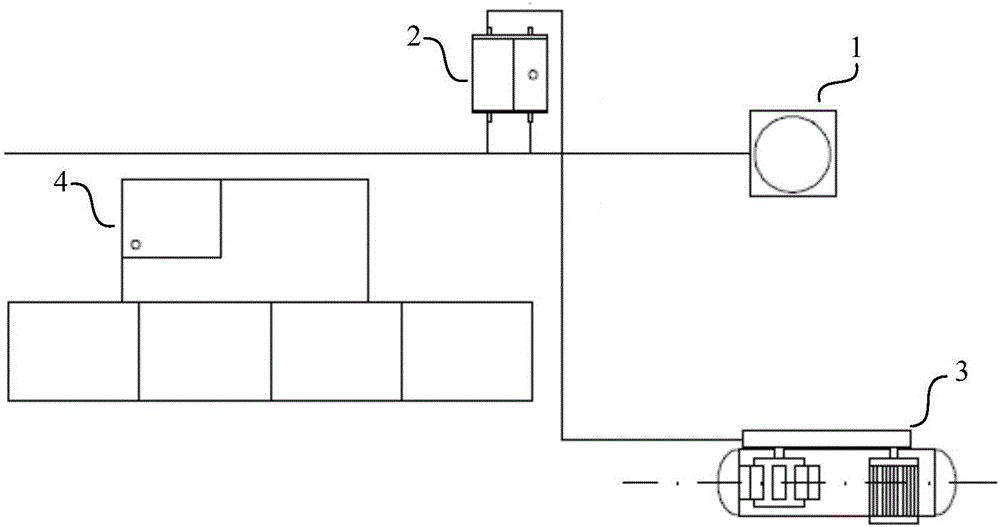

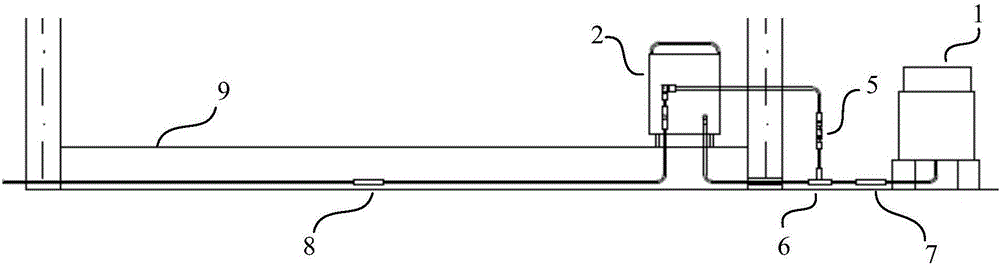

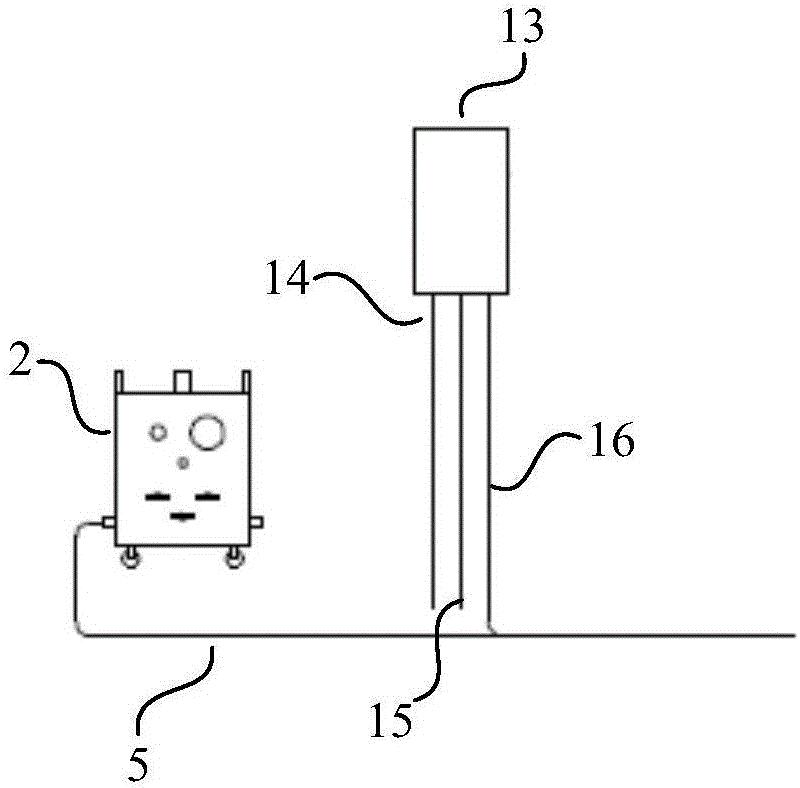

[0034] See Figure 1-3 , The small high-temperature and high-pressure test system of the present invention includes the pressurization system integration 2, the temperature control box 4 and the distribution box 13 installed in the operation room, and the ultra-high pressure test container 1 and the air compressor 3 installed outside the operation room; The pressure integrated system 2 is placed on the anti-static floor 12. The air inlet of the pressurization integrated system 2 is connected to the air compressor 3 through a compressed air hose 5, the air outlet is connected to the air inlet of the ultra-high pressure test vessel 1, and the pressure relief port is discharged through a pressure relief pipe; The air inlet of the system integration 2 is set at the top, and the air outlet and the pressure relief port are located at the bottom. The air inlet of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com