Lightweight method of super-large three-dimensional model of carrier rocket

A launch vehicle and three-dimensional model technology, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve the problems that affect the final assembly design and the use efficiency of aerospace product models, the long interference check calculation process, and the final assembly results cannot be browsed. , achieve good application effect and promotion value, improve design and secondary operation speed, and quickly enter the working state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

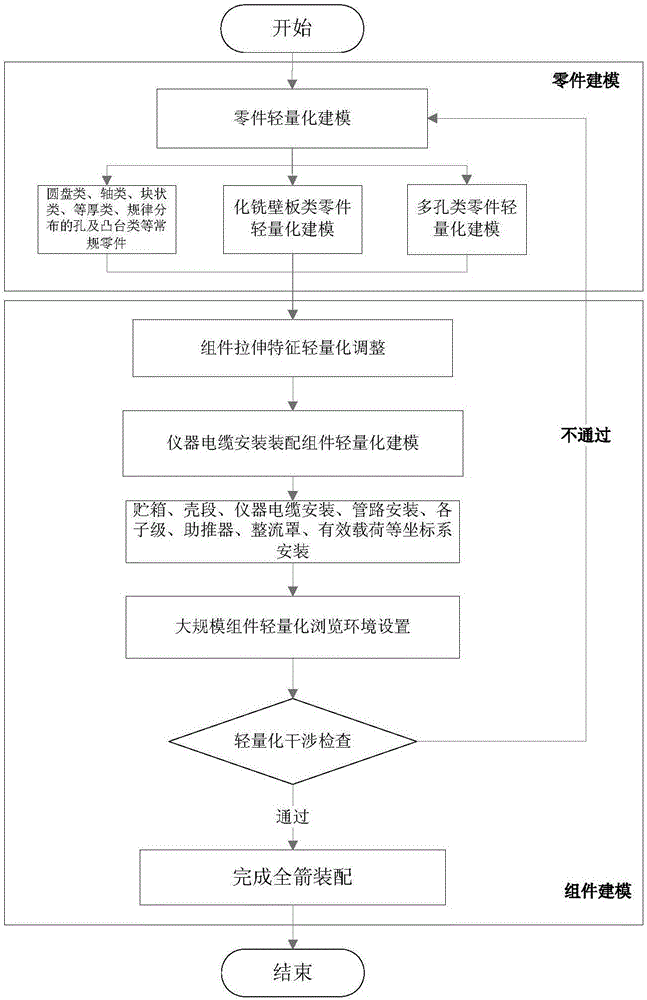

[0042] Below in conjunction with accompanying drawing and example the present invention is described in detail, as figure 1 , 2 Shown, the steps of the present invention are as follows:

[0043] (1) Carry out three-dimensional lightweight modeling of conventional parts of the launch vehicle in the Creo environment, and the conventional parts are other parts of the launch vehicle except chemical milling wallboard parts and porous parts;

[0044] First establish the reference features, and then follow the principle of "main features first, auxiliary features later" to establish all features. All features must be fully positioned, under-positioning is not allowed, and positioning methods such as parallel, vertical, and coincidence are preferred;

[0045] Secondly, create all the features required by the part, and omit the internal thread, external thread, undercut and other features that cause the model to be large in scale and unnecessary;

[0046] Shaft and disk parts are mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com