High voltage vacuum circuit breaker

A vacuum circuit breaker and high-voltage technology, applied in high-voltage air circuit breakers, high-voltage/high-current switches, circuits, etc., can solve problems such as wear and air leakage, change the vacuum pressure state, etc., to achieve stable and reliable contact, synchronization, and convenience. The effect of manual opening and closing

Inactive Publication Date: 2018-07-10

杭州崇恒电力技术有限公司

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The technical problem to be solved by the present invention is that the plug-in opening and closing switch adopted by the existing vacuum switch tube will change the state of vacuum pressure and easily cause wear and air leakage

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0104] Example: The mass ratio of raw materials for the insulation reinforcement layer is 81 parts of clay, 39 parts of quartz sand, 49 parts of feldspar, 36 parts of silicon carbide, 25 parts of mica powder and 2 parts of calcium oxide.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

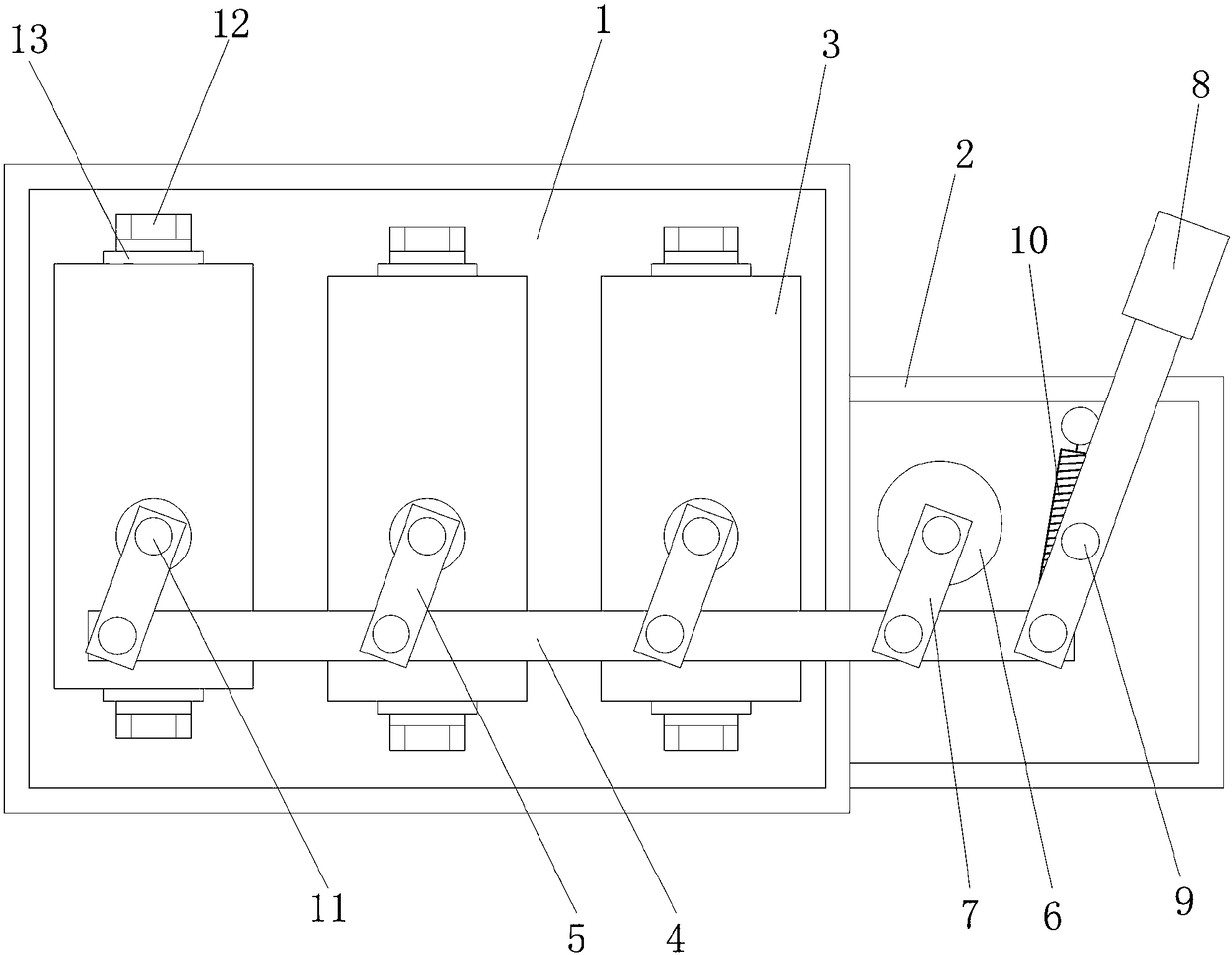

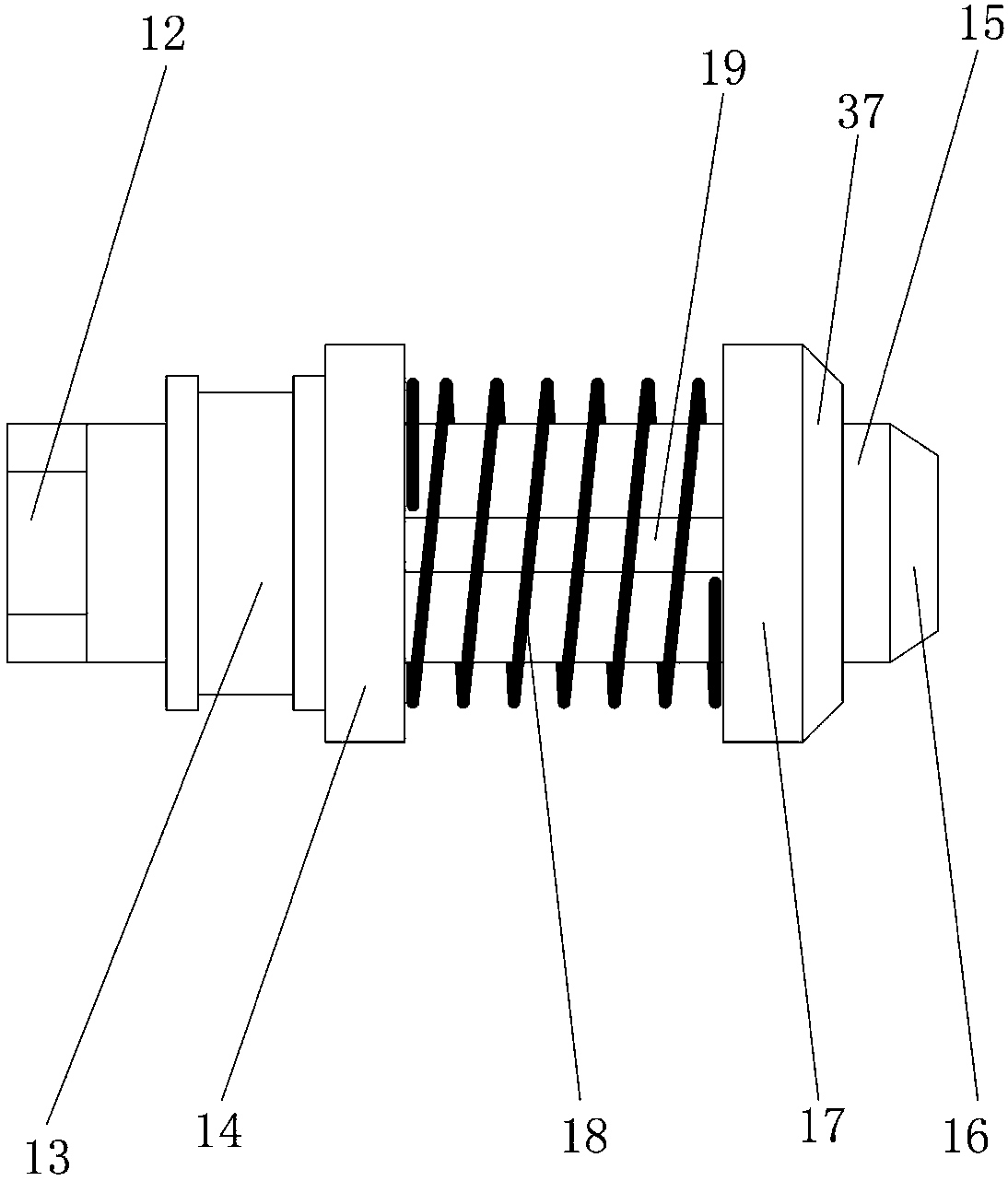

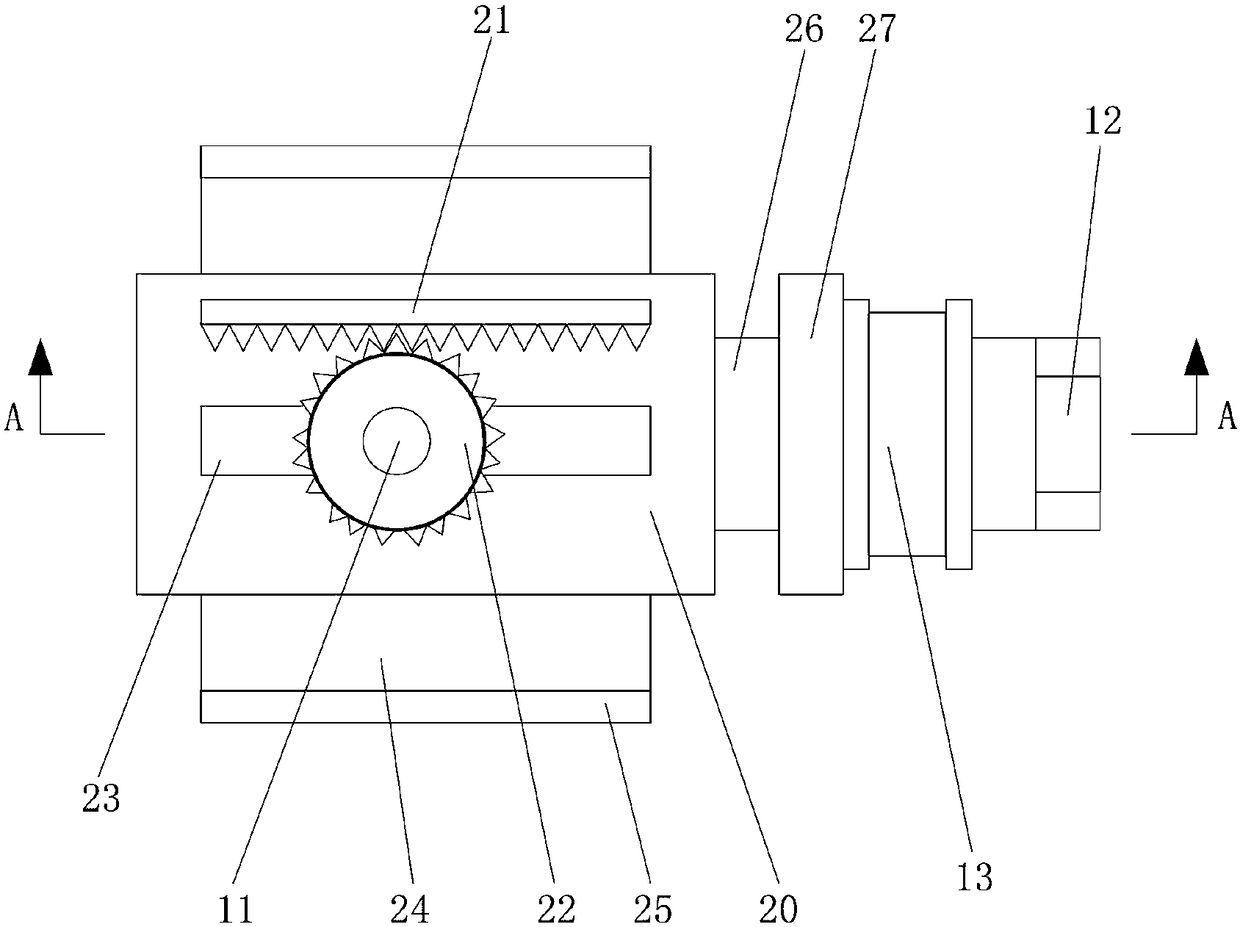

The invention provides a high-pressure vacuum breaker which comprises a switching tube assembly box, a switching-on / off control box, a linking bar, three connecting rods, a driving steering engine, a switching-on / off handle, a tension spring and three vacuum switching tubes. The vacuum switching tubes of the high-pressure vacuum breaker can be used for controlling switching-on and off of a fixed contact and a movable contact by adopting a rotary driving mechanism, and the vacuum air pressure state inside the vacuum switching tubes cannot be influenced in the switching-on and off processes. The high-pressure vacuum breaker has better application prospects.

Description

technical field [0001] The invention relates to a circuit breaker, in particular to a high-voltage vacuum circuit breaker. Background technique [0002] At present, outdoor high-voltage vacuum circuit breakers are mainly used for breaking and closing load currents, overload currents and short-circuit currents in power systems; they are suitable for power systems (including power plants, substations, power transmission and distribution lines, and industrial and mining enterprises) The control and protection of high-voltage vacuum circuit breakers are most widely used in urban distribution networks and rural power grids. The development trend of high-voltage vacuum circuit breaker equipment in recent years is to increase energy conservation and environmental protection, strengthen miniaturization, high reliability and less (free) maintenance switchgear research and development; The safe and reliable operation of the core part of the vacuum switch tube is of great significance ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01H33/666

CPCH01H33/666H01H2033/6667

Inventor 宋竹生鲁兹·克拉夫特金敬福施张军沈志宏董传君

Owner 杭州崇恒电力技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com