Insulating structure of stator slots of flat wire motor and manufacturing process thereof

A motor stator and stator slot technology, applied in the shape/style/structure of winding insulation, laying solid insulation, electric components, etc., can solve the problem of increasing the thermal resistance between conductors and stator cores, affecting the conductor occupation in the slot Improve the area ratio, increase the power density of the motor, etc., to achieve the effect of increasing the full rate of the stator slot, saving the space in the stator slot, and improving the production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

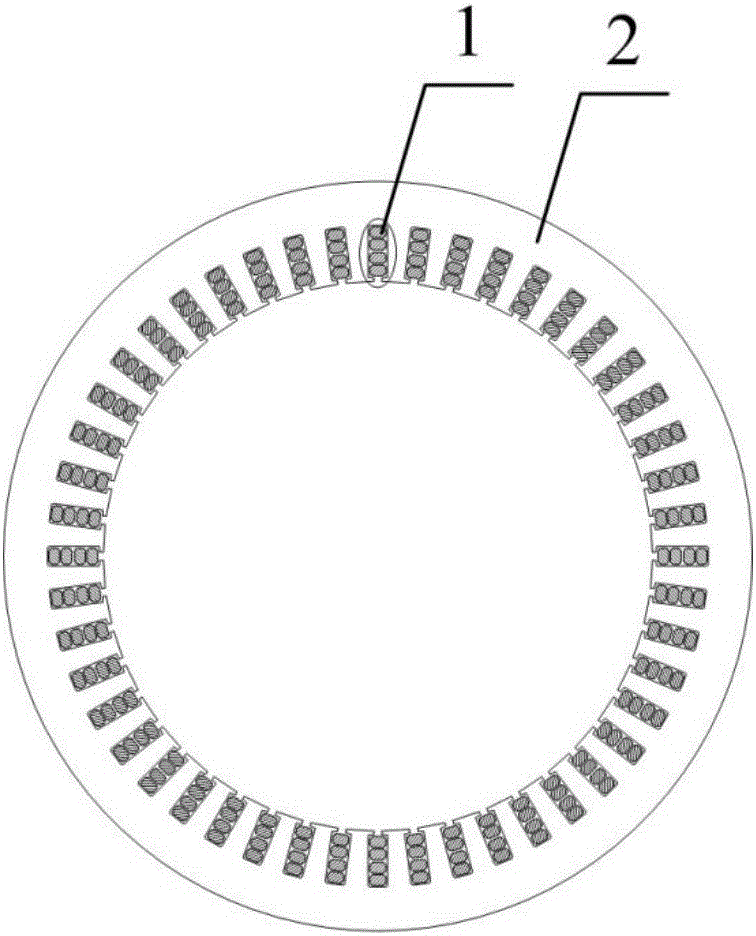

[0026] figure 1 It is a schematic diagram of the stator structure of a flat wire motor, wherein 1 is a stator slot and 2 is a stator core. The inside of the stator slot 1 is a flat wire conductor. In this embodiment, four flat wire conductors are arranged inside each stator slot as an example.

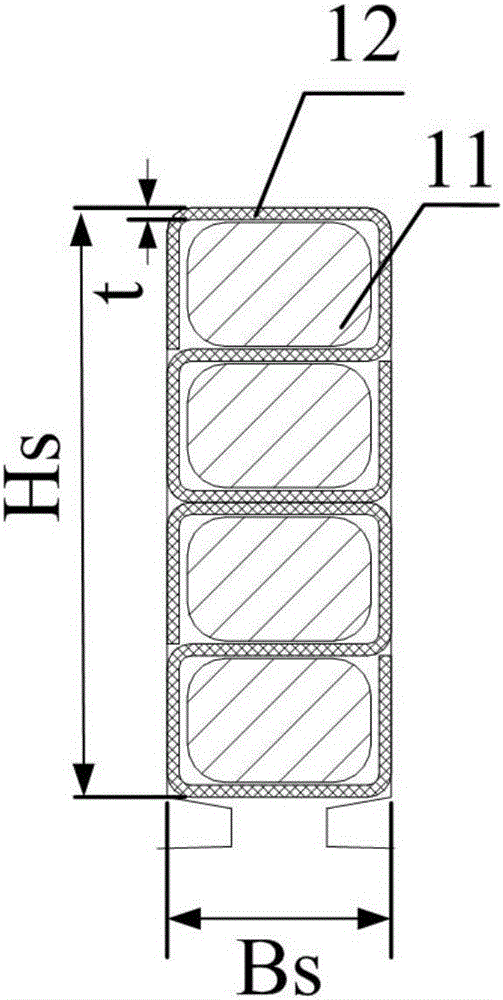

[0027] figure 2 It is an enlarged schematic diagram of the internal insulation structure of the stator slot of the existing flat wire motor, wherein 11 is a flat wire conductor, and 12 is insulating paper, and the flat wire conductors 11 are arranged side by side in the stator slot 1, and the insulating paper 12 is folded into The B-shaped structure is placed between the conductors of the flat wire conductor 11 and between the flat wire conductor 11 and the stator slot 1. The width of the stator slot 1 is Bs and the height is Hs. The insulating paper The thickness of 12 is t, then the effective slot area of the stator slot 1 is (Bs-2*t)*(Hs-6t).

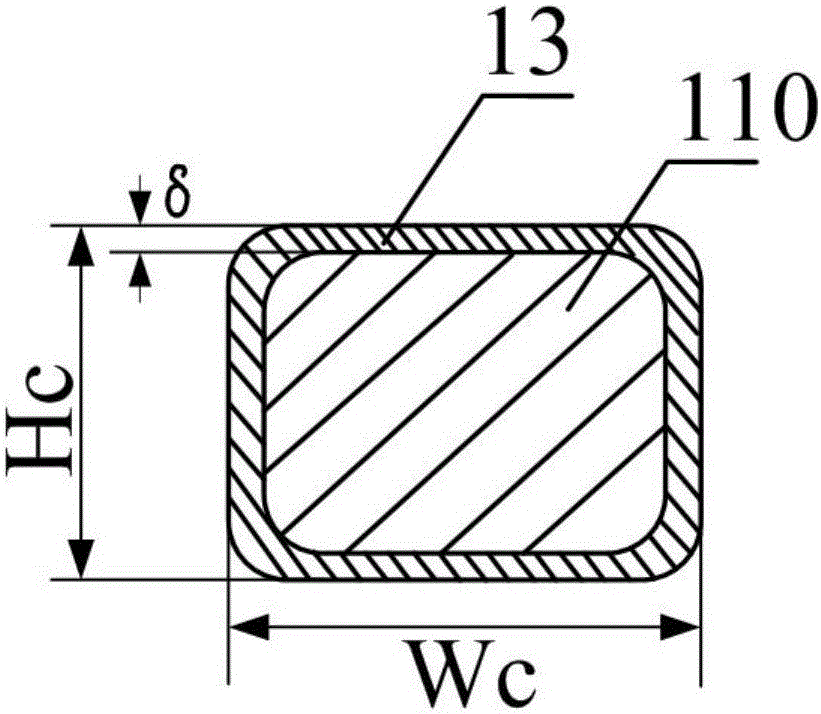

[0028] image 3 It is an enlarge...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap