Fiber optic cable assembly for terminating fiber optic cable and method of manufacture

A fiber optic cable and cable technology, applied in the coupling of optical components, optical waveguides, optics, etc., can solve the problems of different combinations, difficult to use connectors to terminate cables, not easy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

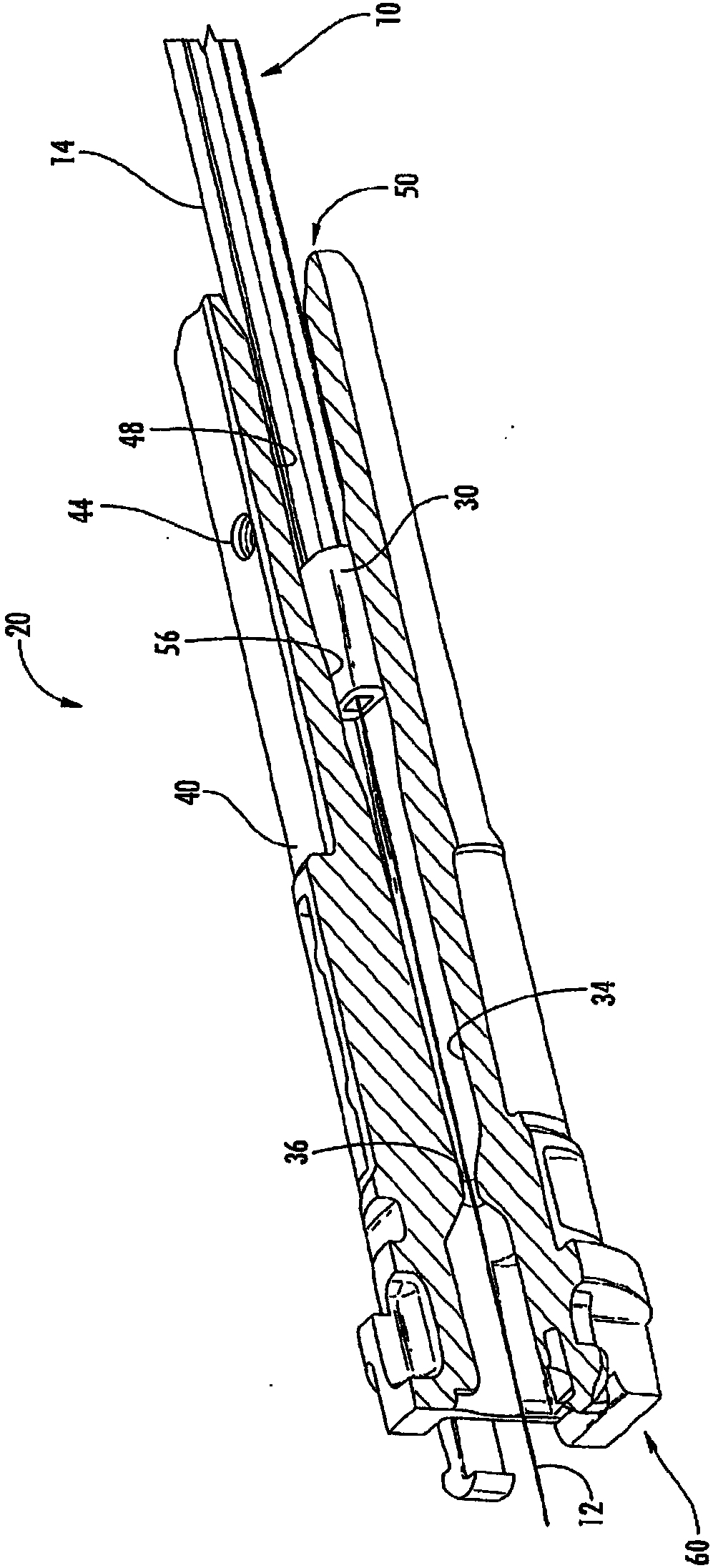

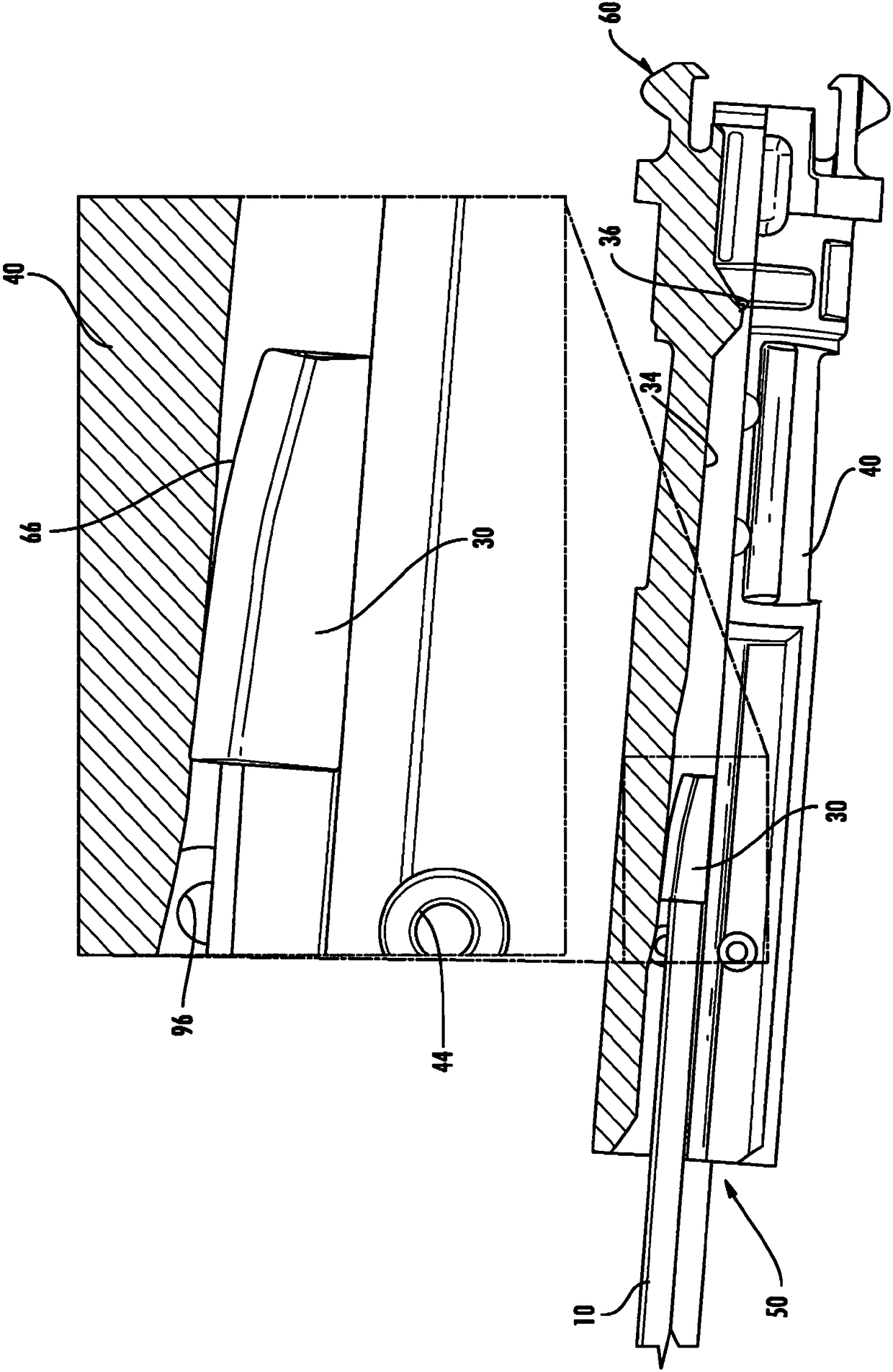

[0026] figure 1 is a cutaway view showing the steps of terminating the cable 10 according to the first embodiment. For example, cable 10 may be a fiber optic cable having, for example, one or more optical transmission components, such as one or more optical fibers 12 . Instead of, or in addition to, optical transmission components, other data, voice, etc., and other information transmission media, like metallic conductors for example, may be included. In the illustrated embodiment, the optical transmission component comprises a plurality of optical fibers 12 . The cable 10 may also have, for example, a polymer jacket 14 and one or more pigtails or strength members 16 ( Figure 8 shown in ).

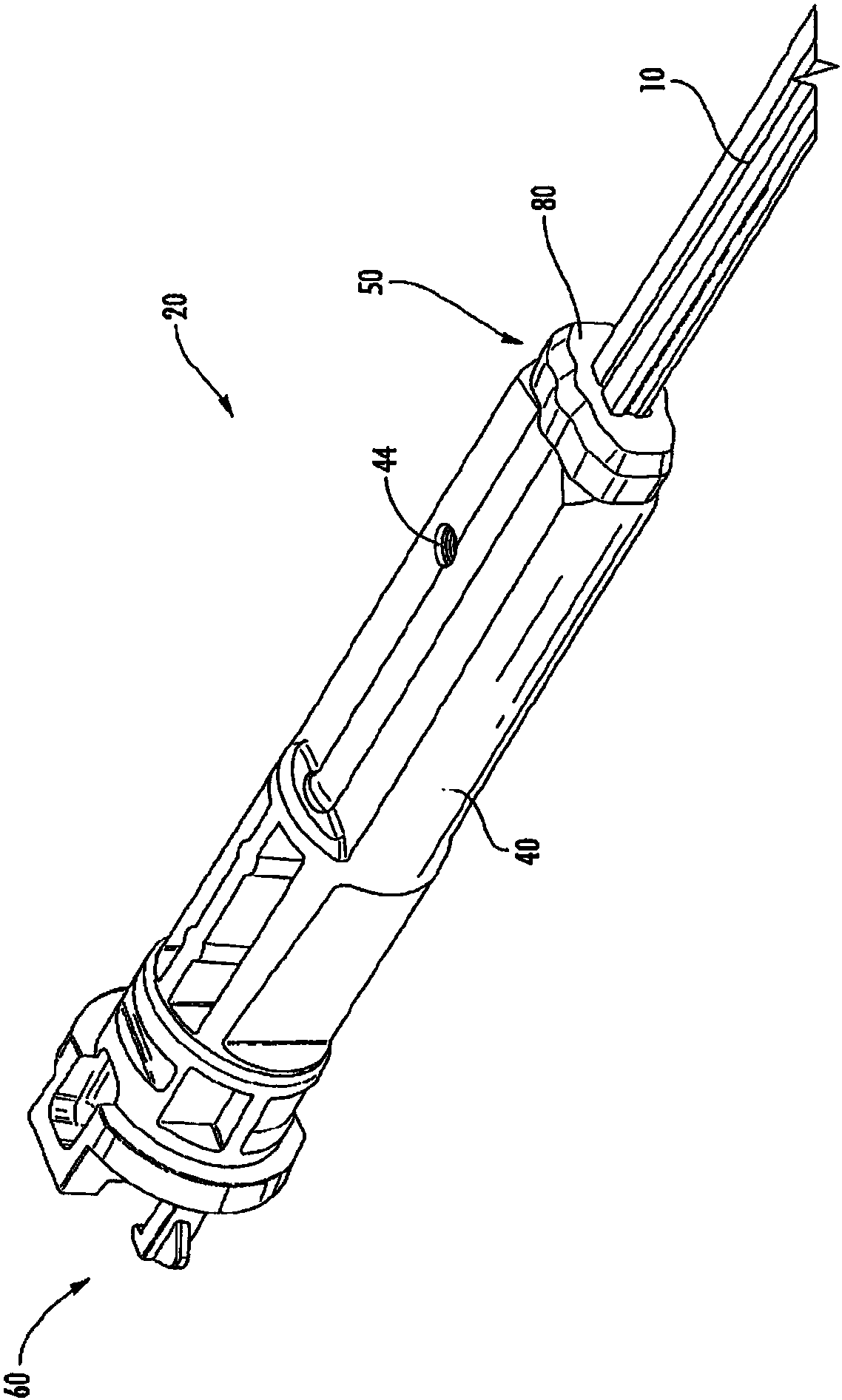

[0027] figure 2 is a perspective view of a subassembly of a terminated cable 20 (also known as a "connectorized" cable). The sub-assemblies may ultimately be formed into fiber optic cable assemblies having hardened fiber optic connectors at their ends ( Figure 12 shown in ). refe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com