Winter-heating vacuum greenhouse without supports, stand columns and quilts

A column-free and unsupported technology, applied in the field of greenhouses, can solve the problems of increasing the cost of the greenhouse, increasing the cost of users, spending more manpower and time, and achieving the effects of simplifying construction steps, slow heat transfer, and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

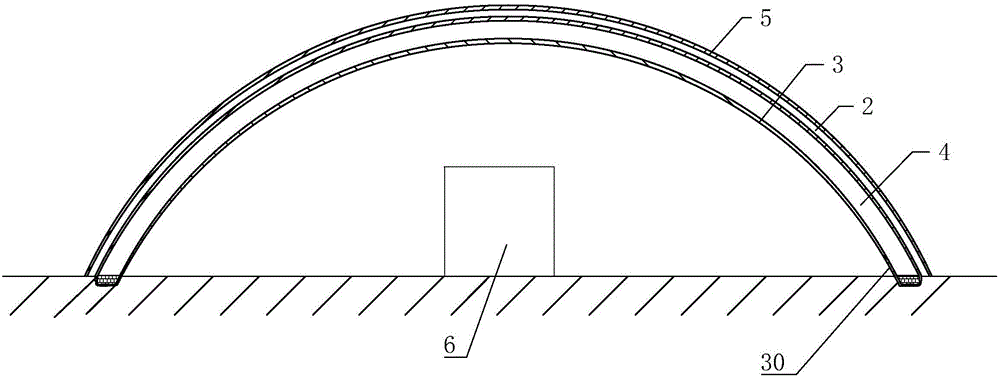

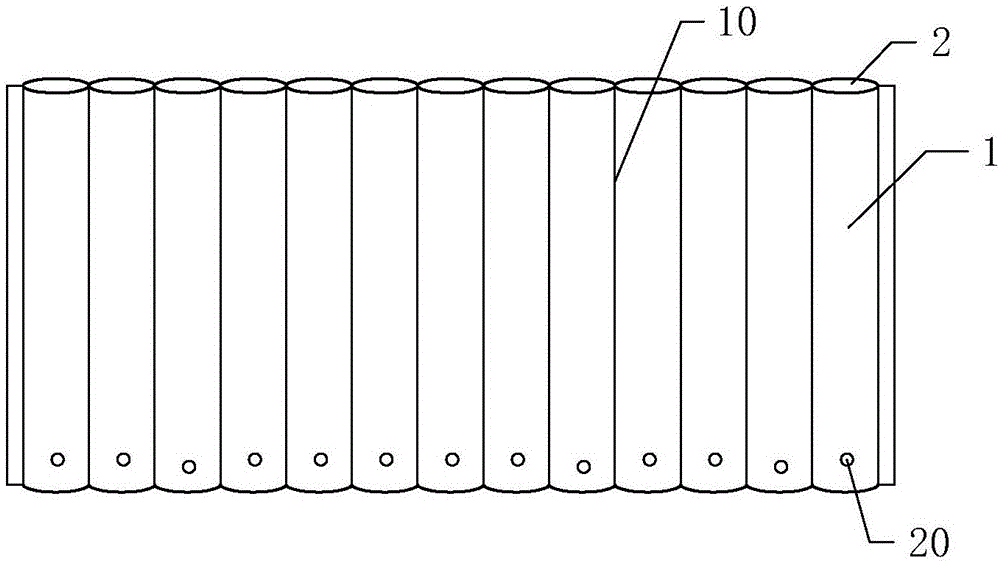

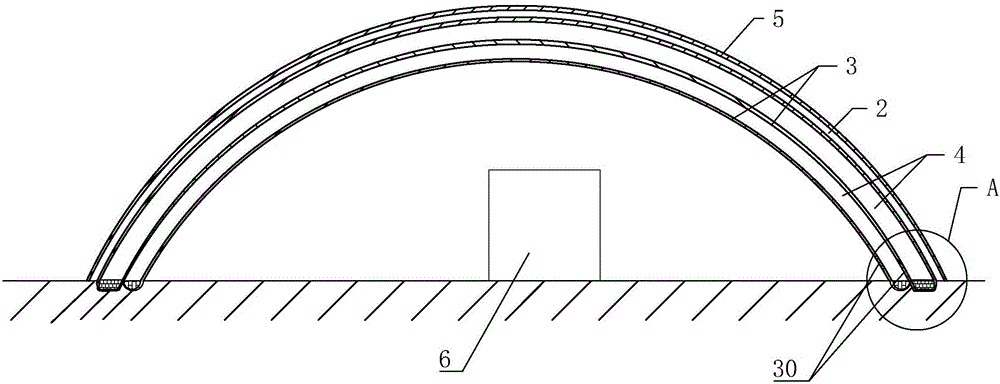

[0019] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, an unsupported, column-free, and quilt-free winter warming vacuum greenhouse includes a shed body 5, and the shed body 5 includes two layers of transparent substrates 1, and the two layers of transparent substrates 1 are fastened together to form a closed body; the two layers of transparent substrates 1 A plurality of connection lines 10 are provided between them, and each connection line 10 runs through the transparent substrate 1, and each connection line 10 connects two layers of the transparent substrate 1 together, and divides the closed body into a plurality of inflatable cylinders 2, each Inflatable holes 20 are provided on the inflatable cylinders 2, and the extension direction of each inflatable cylinder 2 is the span direction of the greenhouse.

[0020] The present invention also includes a heat preservation shed 3 arranged inside the shed body 5. The heat preservation shed 3 is made of a tran...

Embodiment 2

[0026] This embodiment is basically the same as Embodiment 1, the difference is:

[0027] The shed body of this embodiment includes a layer of transparent substrate, and the side of the transparent substrate facing the ground is provided with a plurality of inflatable cylinders arranged side by side, each inflatable cylinder is provided with an inflation hole, and the extension direction of each inflatable cylinder is The span direction of the greenhouse. That is to say, the shed body in this embodiment is composed of a ready-made inflatable cylinder and a transparent substrate, and the inflatable cylinder can be glued or sewn on the transparent substrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com