Atomizer suction nozzle

An atomizer and atomization device technology, which is applied in the field of electronic cigarettes, can solve the problems of tobacco black test, uneven heat distribution, weak smoke taste, etc., and achieve the effect of large smoke volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The specific structure of the atomizer nozzle provided by this embodiment will be described in detail below.

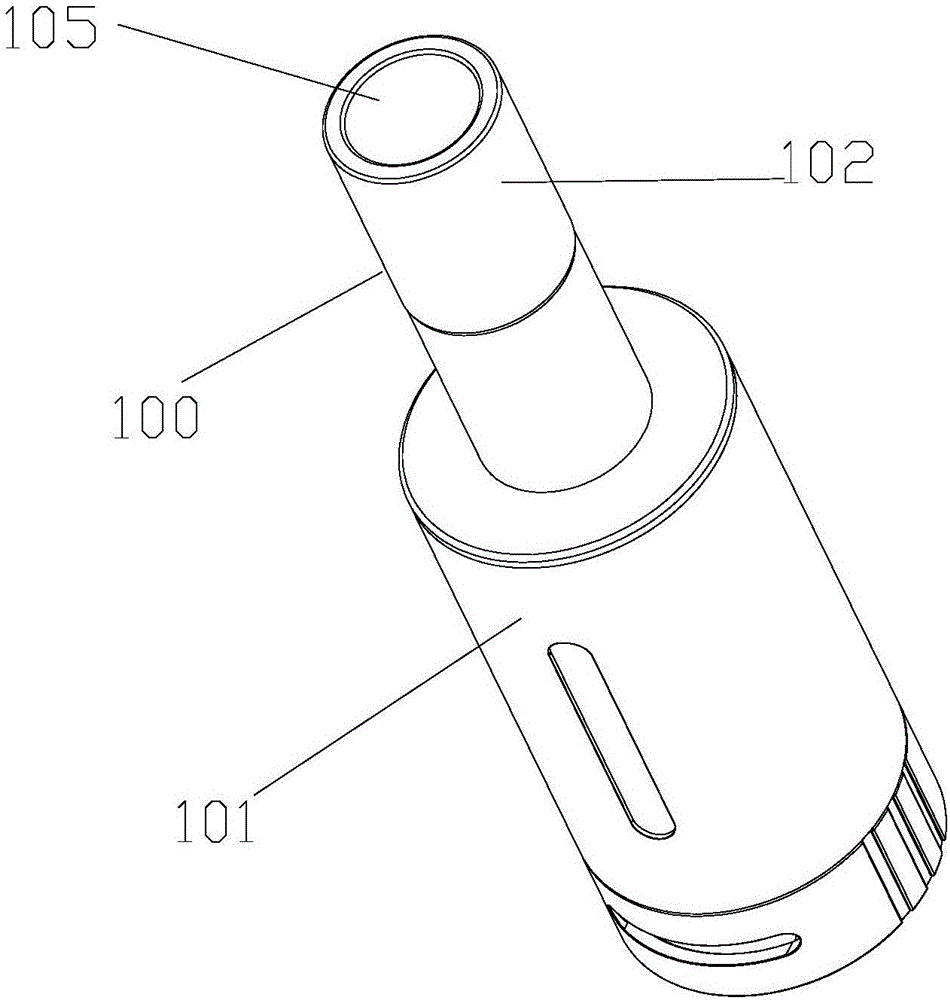

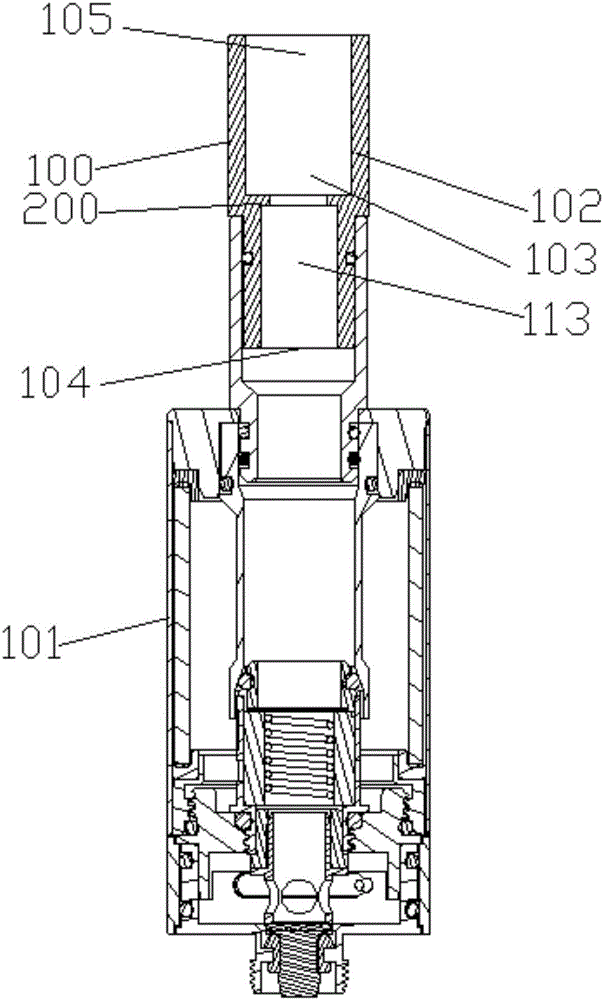

[0038] combine first figure 1 as well as figure 2 As shown, among them, figure 1 It is a schematic diagram of the overall structure of an embodiment of the atomizer provided by the present invention, figure 2 It is a schematic diagram of the overall cross-sectional structure of an embodiment of the atomizer provided by the present invention.

[0039] Specifically, the atomizer nozzle 100 shown in this embodiment is used to be installed on an atomizing device 101 to form an atomizer for inhaling smoke.

[0040] The specific structure of the atomizer nozzle 100 provided in this embodiment will be described in detail below:

[0041] The atomizer nozzle 100 includes a nozzle body 102, and the nozzle body 102 is provided with a smoke flow cavity extending through the nozzle body 102 longitudinally along the nozzle body 102 and used for the flow of smoke. 103....

Embodiment 2

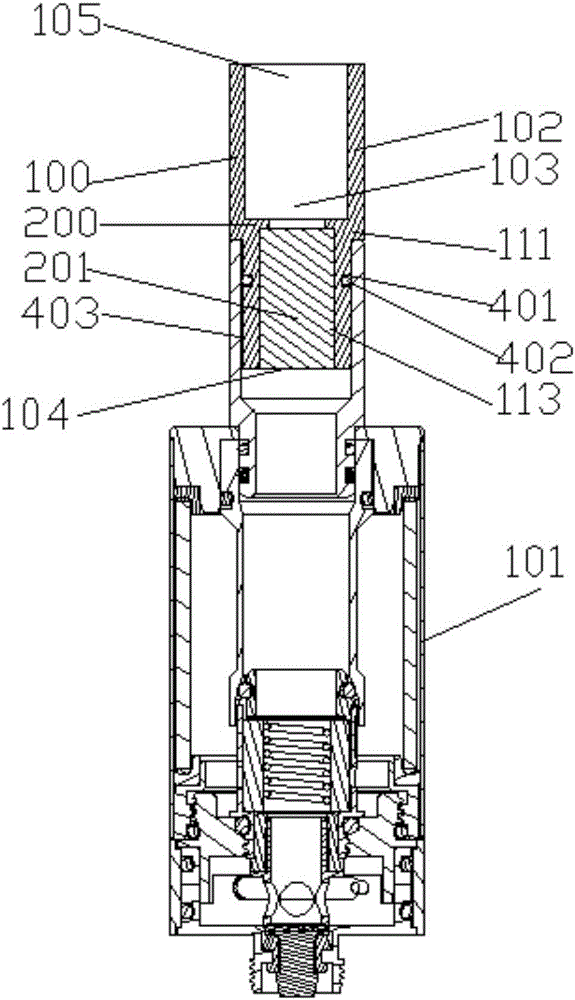

[0067] The specific structure of the atomizer suction nozzle provided in this embodiment is described below:

[0068] Firstly, an optional description is made on the detachable connection between the atomizer nozzle 100 and the atomization device 101 shown in this embodiment:

[0069] a kind of like image 3 , Figure 6 to Figure 9 As shown, among them, Figure 6 It is a schematic diagram of the overall explosive connection structure of an embodiment of the atomizer provided by the present invention, Figure 7 It is a schematic diagram of the cross-sectional structure of the explosive connection of another embodiment of the atomizer provided by the present invention, Figure 8 It is a schematic diagram of the overall explosive connection structure of another embodiment of the atomizer provided by the present invention, Figure 9 It is a schematic diagram of the cross-sectional structure of the explosive connection of another embodiment of the atomizer provided by the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com