Sand separating and washing machine

A sand washing machine and sand separation technology, which is applied in the field of sand washing machines, can solve the problems of low cleaning degree, inability to separate sand and gravel, and backward production capacity, and achieve high sand washing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

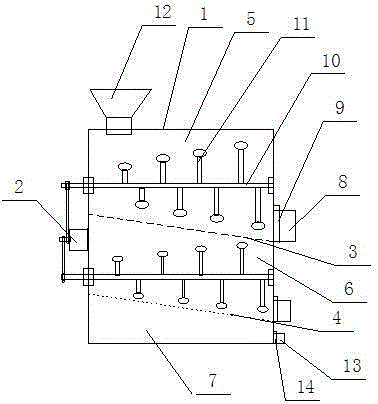

[0019] to combine figure 1 The shown sand washing machine includes a sand washing cylinder 1 and a driving motor 2. A coarse sand washing screen 3 and a fine sand washing screen 4 are arranged in the sand washing cylinder 1 from top to bottom. The sieve 3 and the fine sand washing screen 4 are arranged in parallel and inclined. The coarse sand washing screen 3 and the fine sand washing screen 4 divide the sand washing cylinder 1 from top to bottom into a rough sand washing chamber 5 and a fine washing sand chamber. 6 and the slag storage chamber 7, the coarse sand washing chamber 5 and the fine sand washing chamber 6 are all provided with stirring sand washers, and the stirring sand washers are driven by the driving motor 2.

[0020] In this embodiment, a sand outlet 8 is provided on the sand washing cylinder 1 at the lower end of the coarse sand screen 3 and the fine sand screen 4 .

[0021] In this embodiment, the sand outlet 8 is provided with a sand outlet gate 9 .

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sieve aperture | aaaaa | aaaaa |

| Sieve aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com