Repair welding process used after thread blind hole depth difference exceeding

A threaded blind hole and repair welding technology, which is applied in the field of transformer production, can solve problems such as unrepairable deformation after welding, unusable flanges, waste of labor, material costs, etc., to reduce material costs and repair costs, and quickly restore use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

[0020] A repair welding process after the depth of a threaded blind hole is out of tolerance, comprising the following process steps:

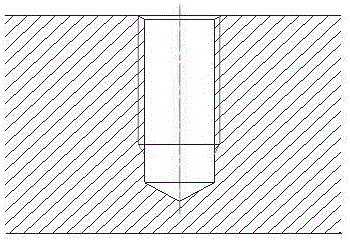

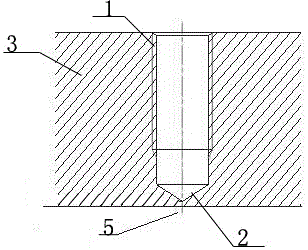

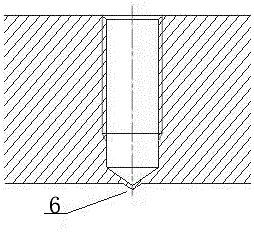

[0021] Process the threaded blind hole on the front of the workpiece 3. If the bottom hole of the threaded blind hole is too deep, analyze the situation of the bottom hole too deep, which can be divided into three types: A, top penetration 7, the hole depth of the threaded blind hole 1 is too large, and the bottom hole is tapered The cone tip of the end 2 penetrates the back of the workpiece 3; B, the protrusion 6, the hole depth of the threaded blind hole is too large, and the cone tip of the conical end of the bottom hole pushes up the back surface of the workpiece, but has not yet penetrated the workpiece; C. Too thin 5. Although the hole depth of the threaded blind hole is too large, the tapered end of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com