Guide device applied to glass plate deviation rectification

A guiding device and glass plate technology, which is applied in the direction of transportation and packaging, conveyor objects, furnaces, etc., can solve the problems of strong glass plate, glass plate lifting, overturning, loss of correcting guide, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

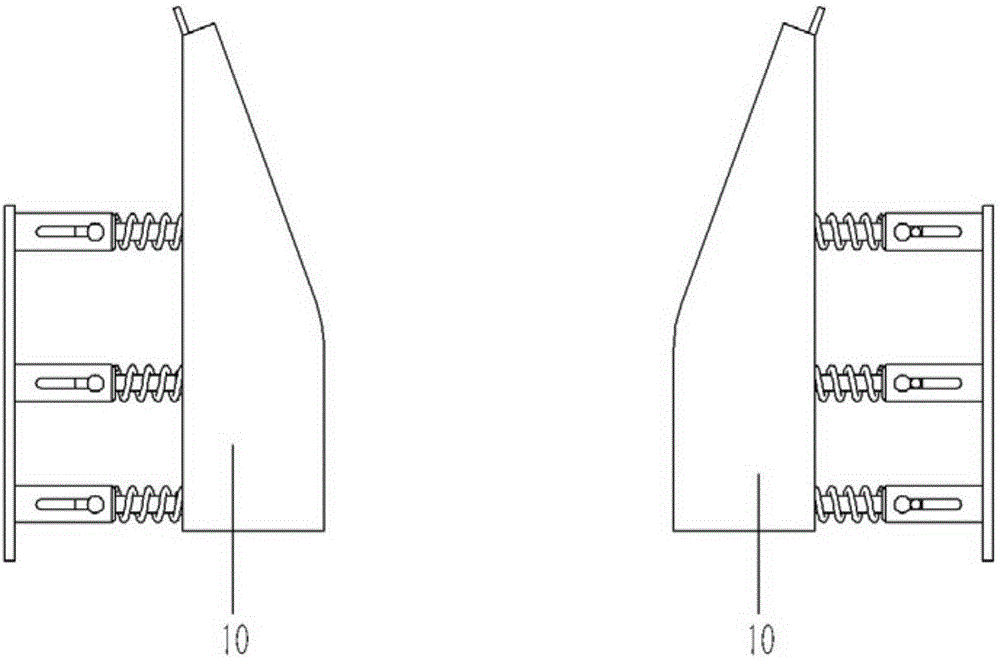

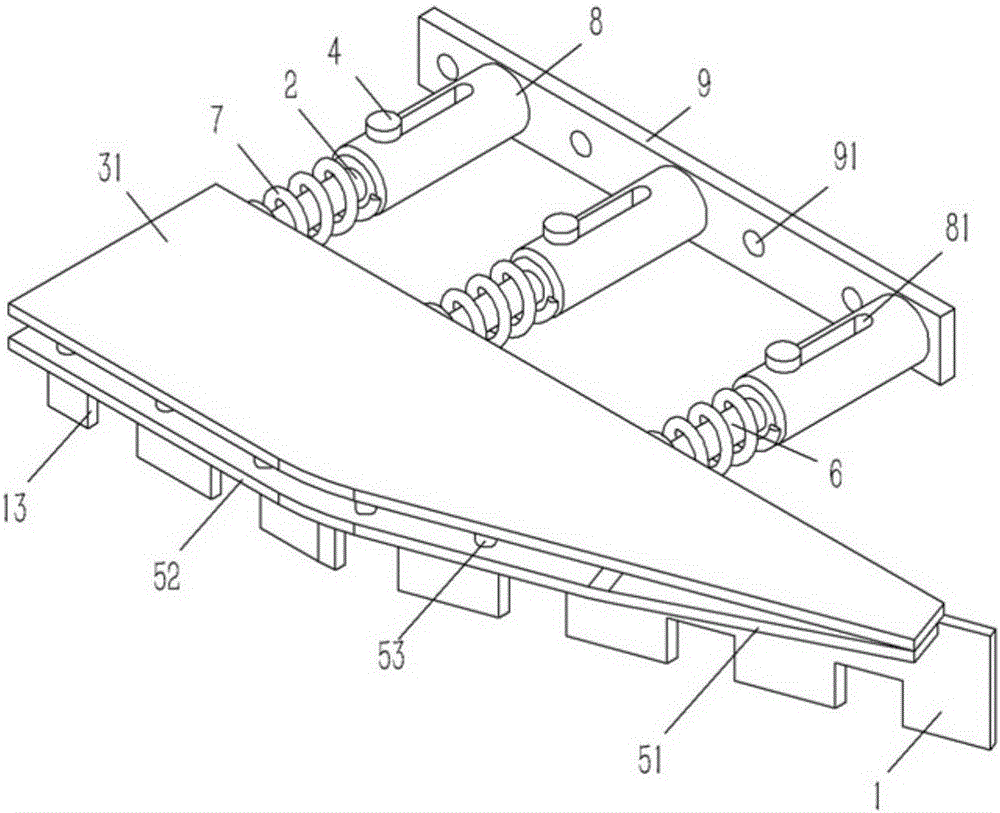

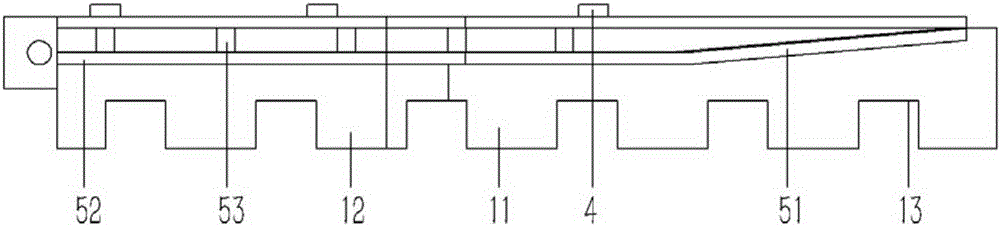

[0023] Example: see Figures 1 to 4 As shown, a guide device applied to deflection correction of glass plates includes a set of relative guide mechanisms 10, the guide mechanism 10 includes a deflection correction plate 1, and the deflection correction plate 1 is composed of an oblique guide plate 11 and a longitudinal side plate 12. The rear end of the plate 12 is fixed with a number of horizontal long support shafts 2, and the longitudinal reinforcement plate 3 is fixed on the sleeve of the long support shaft 2. The front end of the reinforcement plate 3 is fixed on the guide plate 11, and the upper side of the reinforcement plate 3 is bent. A horizontal top plate 31 is folded, and a limit plate 5 is fixed on the side wall of the correction plate 1. The limit plate 5 includes a horizontal flat plate 52, and the front end of the flat plate 52 is formed with an inclined deflector 51. The deflector The front end of 51 is fixed on the top plate 31; the front end of the reinforci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com