Sealing device for biotechnological yoghurt production

A sealing device and technology, applied in the field of sealing devices for biotech yogurt production, can solve problems such as not tight sealing, and achieve the effect of tight sealing and widening vision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

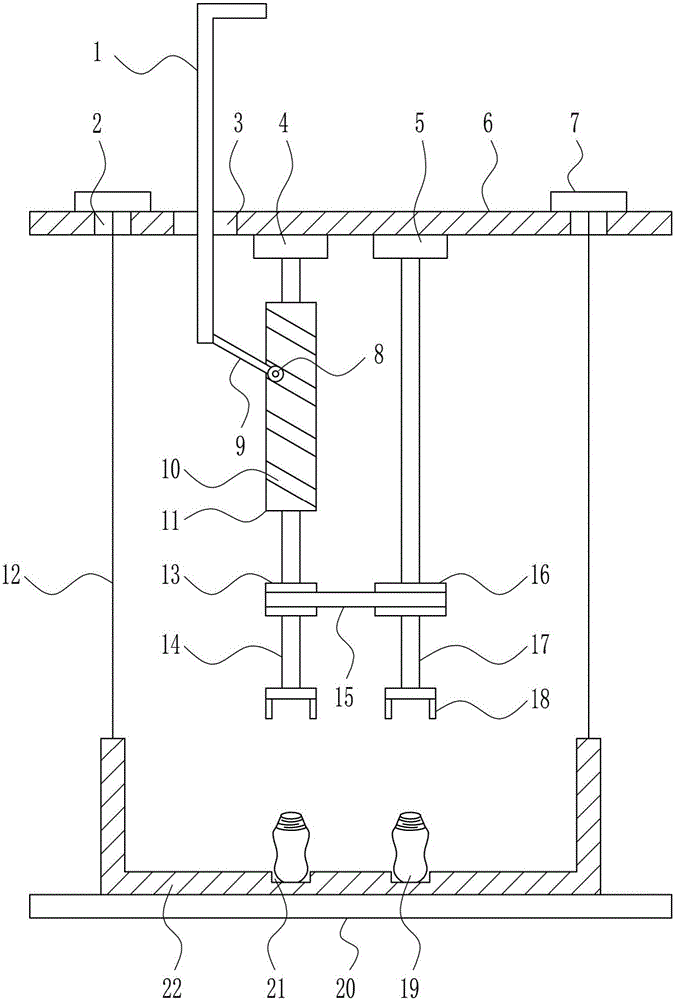

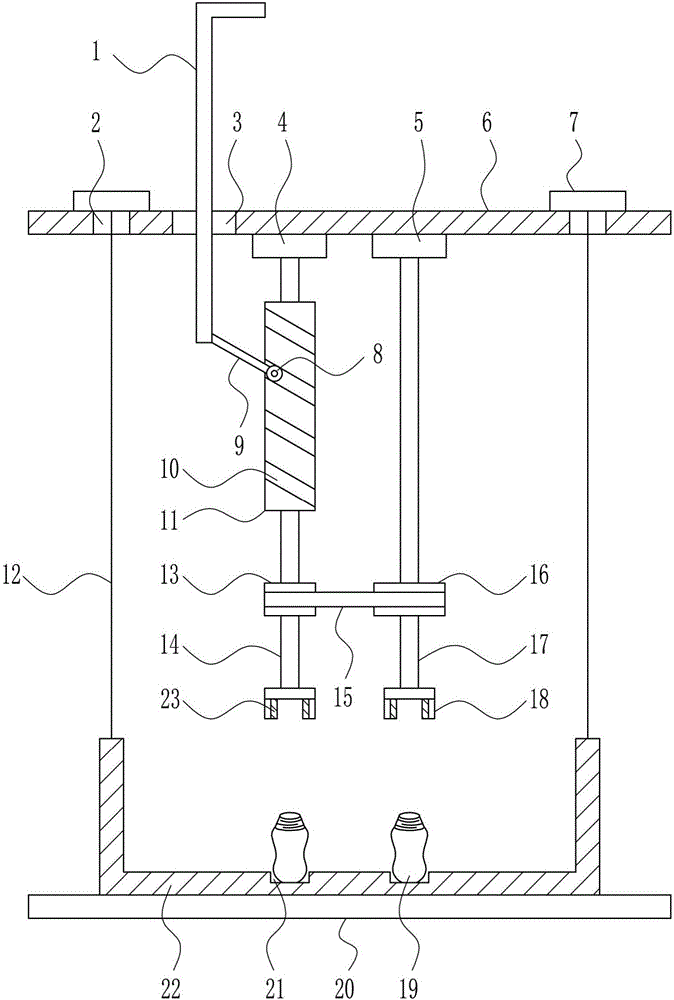

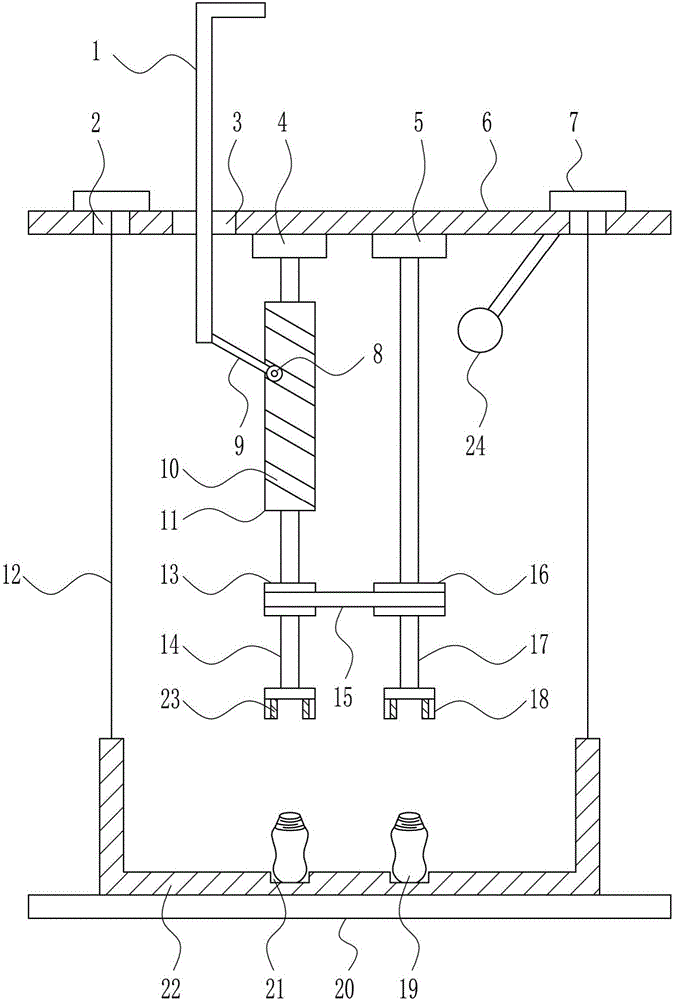

[0024] A sealing device for biotechnology yogurt production, such as Figure 1-3 As shown, it includes a push-pull rod 1, a first bearing seat 4, a second bearing seat 5, a top plate 6, a block 7, a sliding shaft 8, a connecting rod 9, a drum 11, a pull cord 12, a small pulley 13, and a first rotating shaft 14. Flat belt 15, large pulley 16, second rotating shaft 17, thumb cylinder 18, yogurt bottle 19, base 20 and placement frame 22; a placement frame 22 is placed in the middle of the top of the base 20, and the left and right sides of the inner bottom of the placement frame 22 are symmetrically opened There is a rectangular groove 21, a yogurt bottle 19 is placed in the rectangular groove 21, a pull cord 12 is connected to the upper ends of the left and right walls of the placement frame 22, and a top plate 6 is arranged above the base 20, and the left and right sides of the top plate 6 are symmetrically opened with first Through hole 2, one end of stay rope 12 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com