Preparation method of hybrid porous monolith based on mercapto-epoxy click polymerization

A technology of click polymerization and monolithic materials, which is applied in the field of preparation of hybrid porous monolithic materials based on mercapto-epoxy click polymerization, which can solve the problems of cumbersome preparation process, poor mechanical properties, and uneven internal microstructure, etc. The effect of structural uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

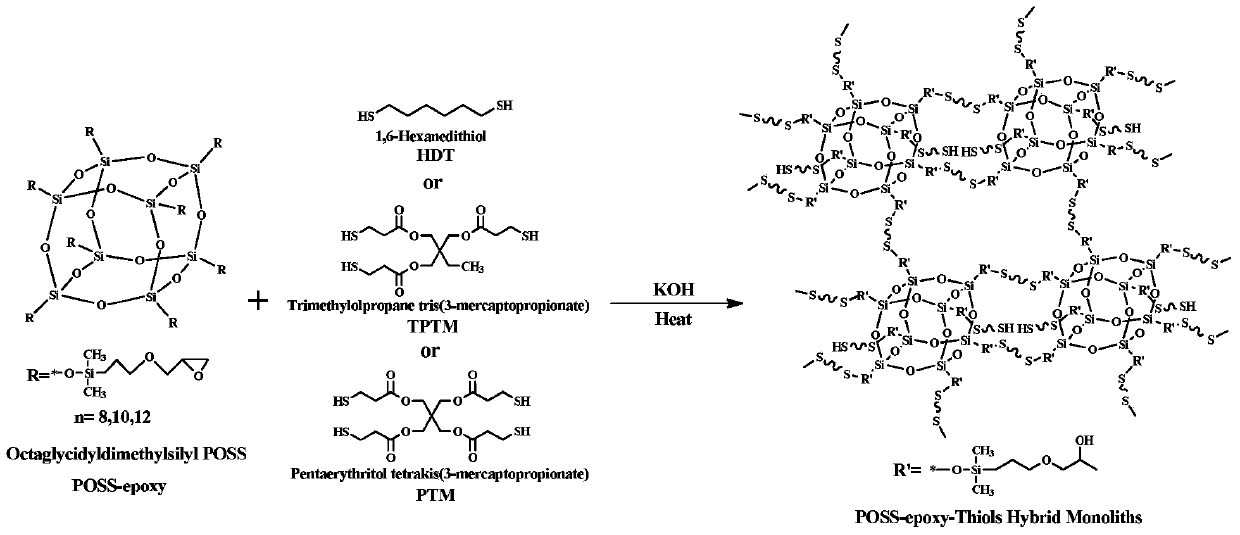

[0032] 1. Add 50 mg of POSS-epoxy reagent to the centrifuge tube.

[0033] 2. Add 26 mg of PTM to the above centrifuge tube.

[0034] 3. Add 280 μL of ethanol to the reaction vessel.

[0035] 4. Add 15 mg of porogen PEG 10,000 to the reaction vessel.

[0036] 5. Add 5 μL of 0.25mol / L KOH aqueous solution into the reaction vessel;

[0037] 6. Ultrasound the above mixed system for 10 minutes in an ice-water bath to completely dissolve it to form a uniform transparent solution, and remove the dissolved oxygen;

[0038] 7. Introduce the prepolymerized solution obtained in step 6 into a capillary tube of 75 μm (inner diameter) that has been pre-sulfhydrylized with a syringe, then seal both ends of the capillary with silica gel, and then seal the centrifuge tube containing the remaining prepolymerized solution Membrane seal.

[0039] 8. Put the capillary and centrifuge tube in step 7 in a water bath at 75°C and react for 1 hour. At this time, the prepolymerization solution in th...

Embodiment 2

[0043] 1. Add 50 mg of POSS-epoxy reagent to the centrifuge tube.

[0044] 2. Add 27 mg of TPTM to the above centrifuge tube.

[0045] 3. Add 260 μL of ethanol to the reaction vessel.

[0046] 4. Add 15 mg of porogen PEG 10,000 to the reaction vessel.

[0047] 5. Add 5 μL of 0.25mol / L KOH aqueous solution into the reaction vessel;

[0048] 6. Ultrasonicate the above mixed system for 5 minutes in an ice-water bath to completely dissolve it to form a uniform transparent solution, and remove the dissolved oxygen in it;

[0049] 7. Introduce the prepolymerized solution obtained in step 6 into a capillary tube of 75 μm (inner diameter) that has been pre-sulfhydrylized with a syringe, then seal both ends of the capillary with silica gel, and then seal the centrifuge tube containing the remaining prepolymerized solution Membrane seal.

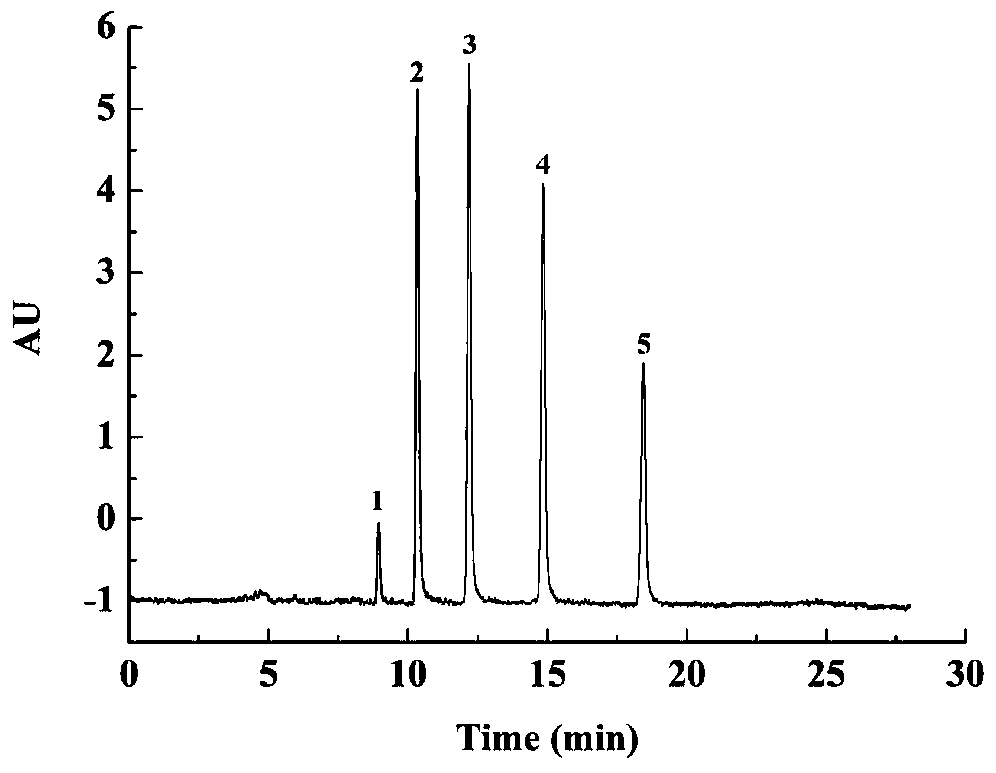

[0050] 8. Put the capillary and centrifuge tube in step 7 in a water bath at 55°C and react for 1 hour. At this time, the prepolymerization solut...

Embodiment 3

[0054] 1. Add 50 mg of POSS-epoxy reagent to the centrifuge tube.

[0055] 2. Add 15 mg of HDT to the above centrifuge tube.

[0056] 3. Add 160 μL of ethanol and 40 μL of 1,4-butanediol to the reaction vessel.

[0057] 4. Add 20 mg of porogen PEG 10,000 to the reaction vessel.

[0058] 5. Add 5 μL of 0.25mol / L KOH aqueous solution into the reaction vessel;

[0059] 6. Ultrasound the above mixed system for 10 minutes in an ice-water bath to completely dissolve it to form a uniform transparent solution, and remove the dissolved oxygen;

[0060] 7. Introduce the prepolymerized solution obtained in step 6 into a capillary tube of 75 μm (inner diameter) that has been pre-sulfhydrylized with a syringe, then seal both ends of the capillary with silica gel, and then seal the centrifuge tube containing the remaining prepolymerized solution Membrane seal.

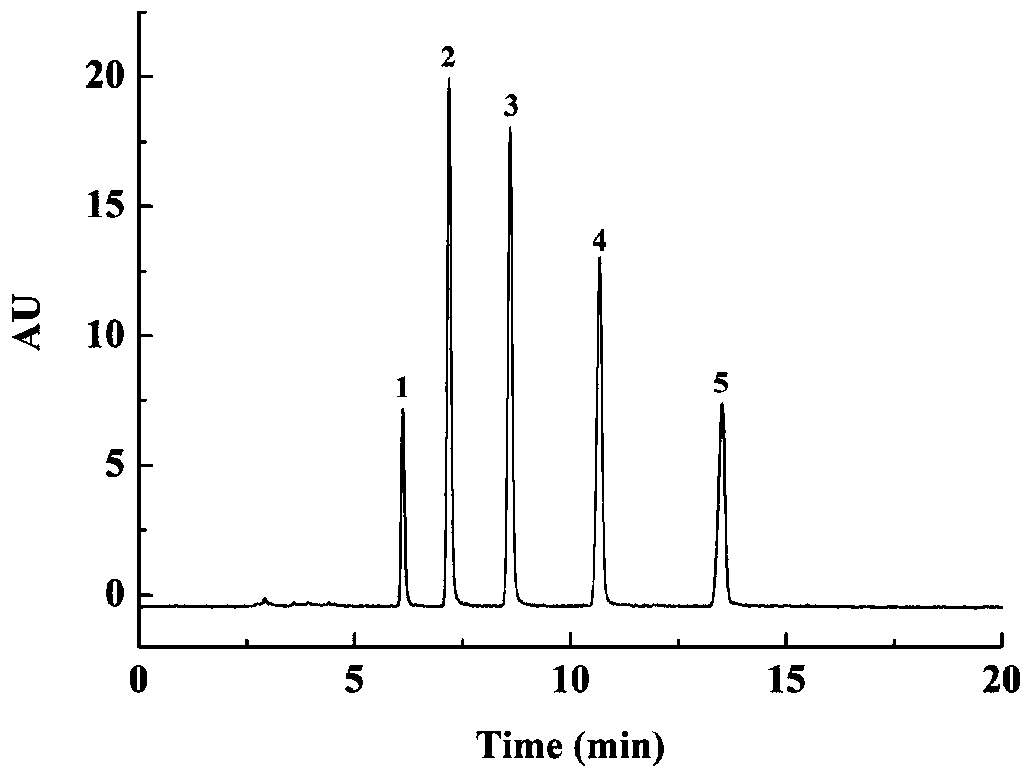

[0061] 8. Put the capillary and centrifuge tube in step 7 in a water bath at 50°C, and react for 1 hour. At this time, the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com