Plastic woven food bag and preparation method thereof

A technology for plastic woven bags and food, applied in the field of plastic woven bag production, can solve the problems of easy breakage, low toughness, affecting food quality, etc., and achieve the effects of suppressing breakage, increasing service life, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

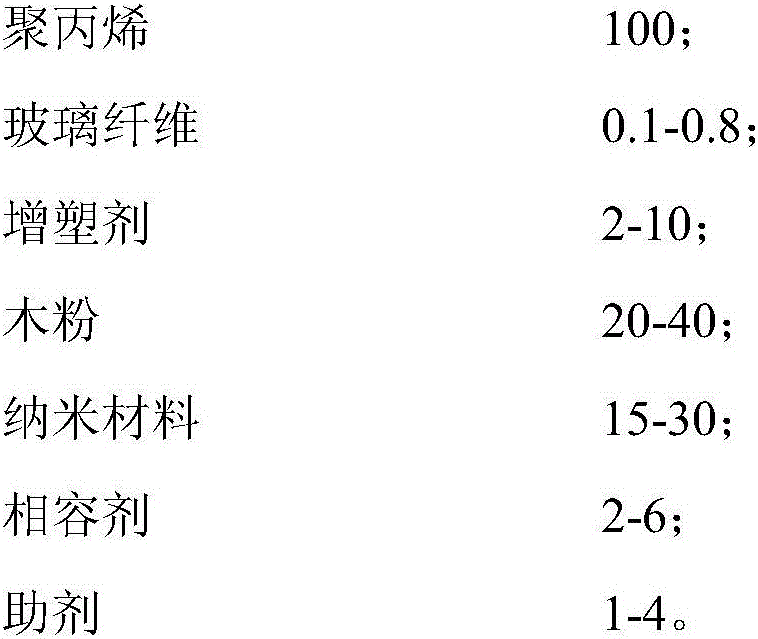

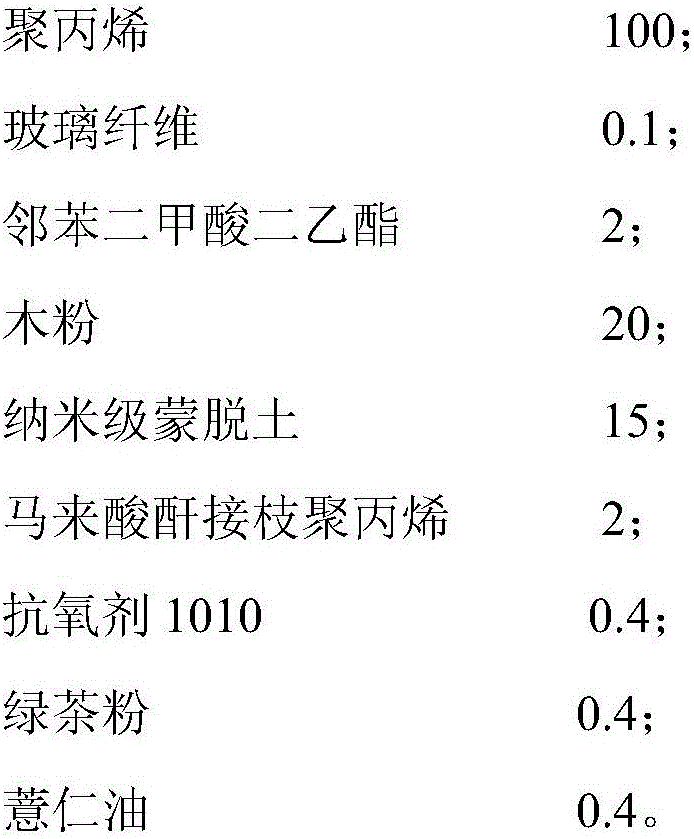

[0016] A food plastic woven bag is made up of the following raw materials in parts by weight:

[0017]

[0018] The length of the glass fiber is 6mm.

[0019] Preparation method: Taking the preparation of a food plastic woven bag as an example, the preparation method of a food plastic woven bag provided in this embodiment is described as follows:

[0020] First, polypropylene, glass fiber, diethyl phthalate, wood powder, nano-sized montmorillonite, maleic anhydride grafted polypropylene, antioxidant 1010, green tea powder and barley oil are fed into a high-speed mixer for heating and melting Mix evenly at a speed of 1000 rpm; then add the above mixture to a twin-screw extruder at a speed of 500 rpm and extrude for 15 minutes. Cloth can get food plastic woven bags.

Embodiment 2

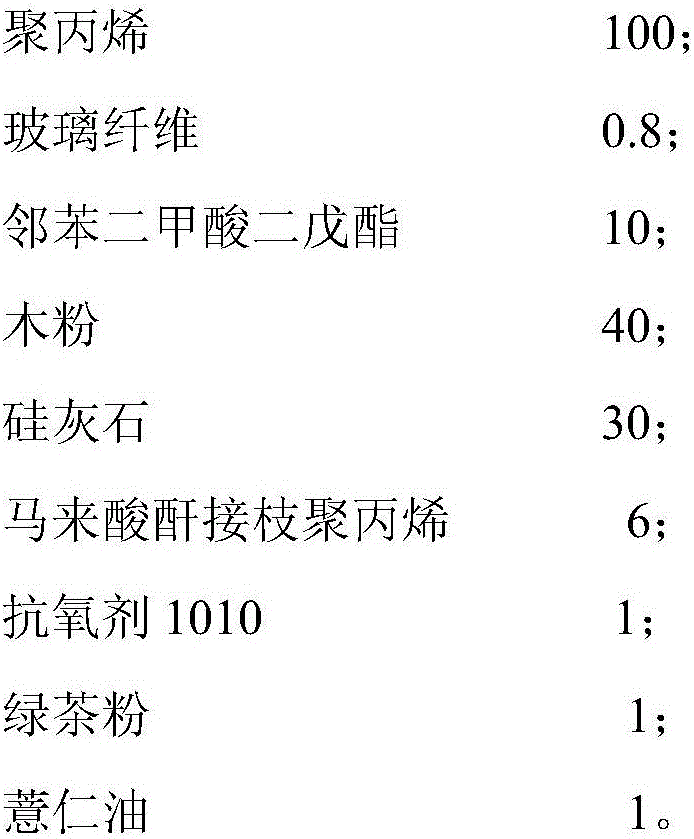

[0022] A food plastic woven bag is made up of the following raw materials in parts by weight:

[0023]

[0024] The length of the glass fiber is 20mm.

[0025] Preparation method: Taking the preparation of a food plastic woven bag as an example, the preparation method of a food plastic woven bag provided in this embodiment is described as follows:

[0026] First, polypropylene, glass fiber, dipentyl phthalate, wood flour, wollastonite, maleic anhydride grafted polypropylene, antioxidant 1010, green tea powder and barley oil are fed into a high-speed mixer for heating, melting and mixing , the rotating speed is 1500 rpm; then the mixture is added to the twin-screw extruder with a rotating speed of 800 rpm and extruded for 10 minutes. Food plastic woven bags are available.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com