Reduction method for automatic moisture absorption device

A hygroscopic device and automatic technology, applied in heating devices, dryers for stationary materials, lighting and heating equipment, etc., can solve problems such as manual handling and mildew of stored items

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

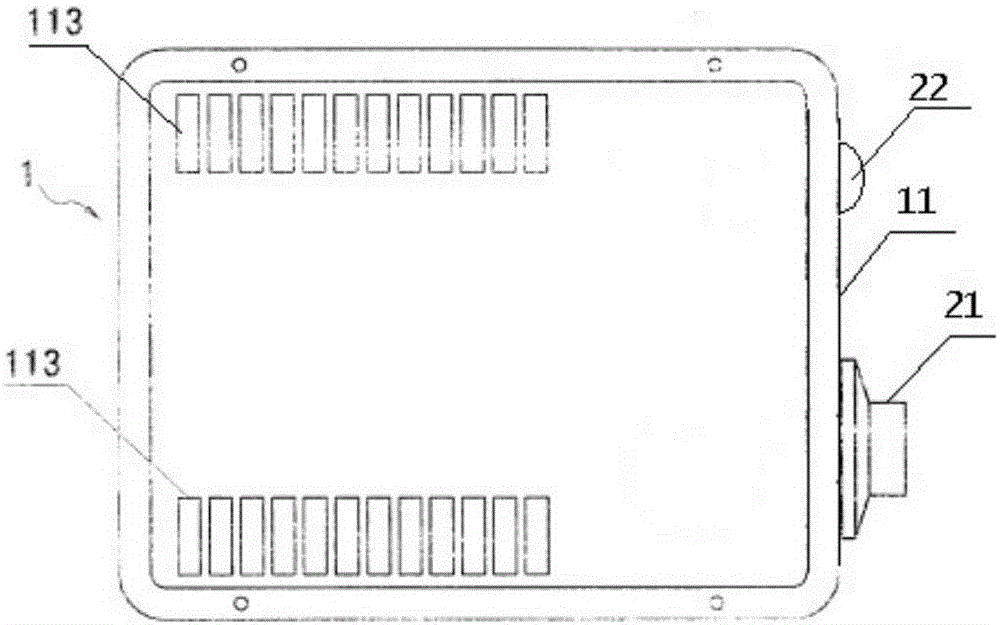

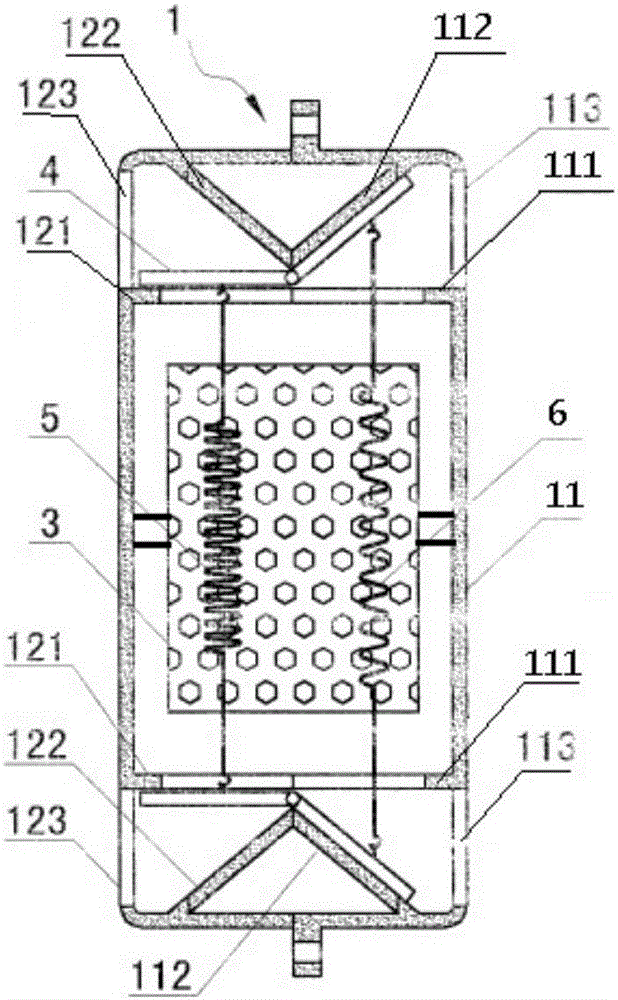

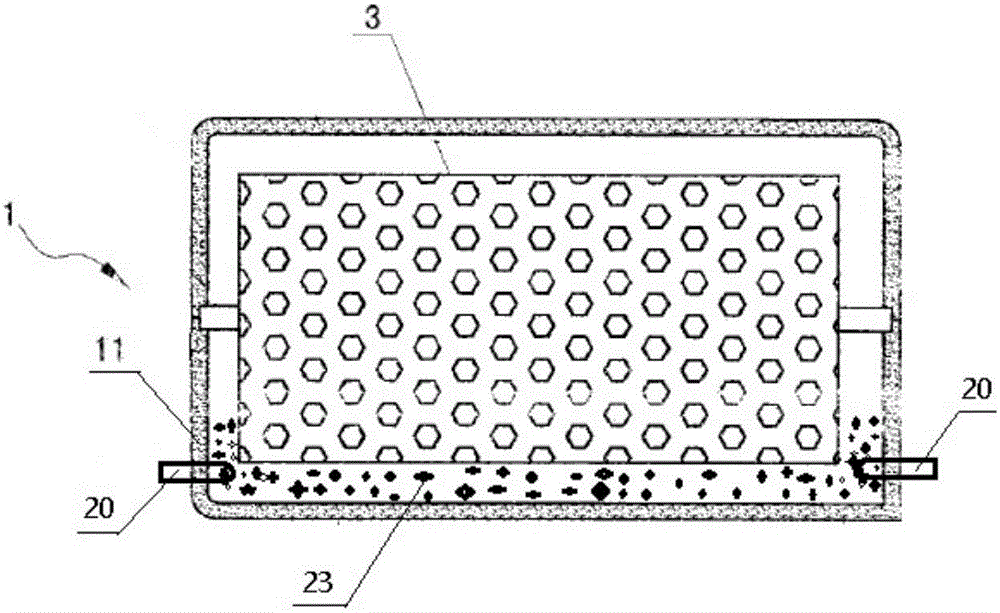

[0016] Such as Figure 1 to Figure 4 As shown, the automatic moisture absorption device 1 is composed of a box body 11, a switch 21, an indicator light 22, an air inlet 113, and an air outlet 123. The box body 11 is also provided with a hygroscopic element 3 (such as recyclable desiccant), a spring 5 , a memory spring 6 and a valve 4 . Both sides of the box body 11 are respectively provided with an air inlet 113 and an air outlet 123'. A vertical seal 111 and an oblique seal 112 are arranged around the air inlet 113 ; a vertical seal 121 and an oblique seal 122 are arranged around the air outlet 123 . As shown in the figure, there are multiple air inlet holes 113 and air outlet holes 123 .

[0017] A PTC heater (not shown) is also arranged inside the hygroscopic element 3 , and the PTC heater is used to heat the hygroscopic element 3 so as to make the hygroscopic element 3 dry and restore.

[0018] Such as image 3 As shown, a conductive agent 23 is also arranged under the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com