Self-priming soup dispenser

A soup feeder and self-priming technology, applied in the field of casting, can solve the problems of long movement stroke, secondary oxidation, impact, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments of the description:

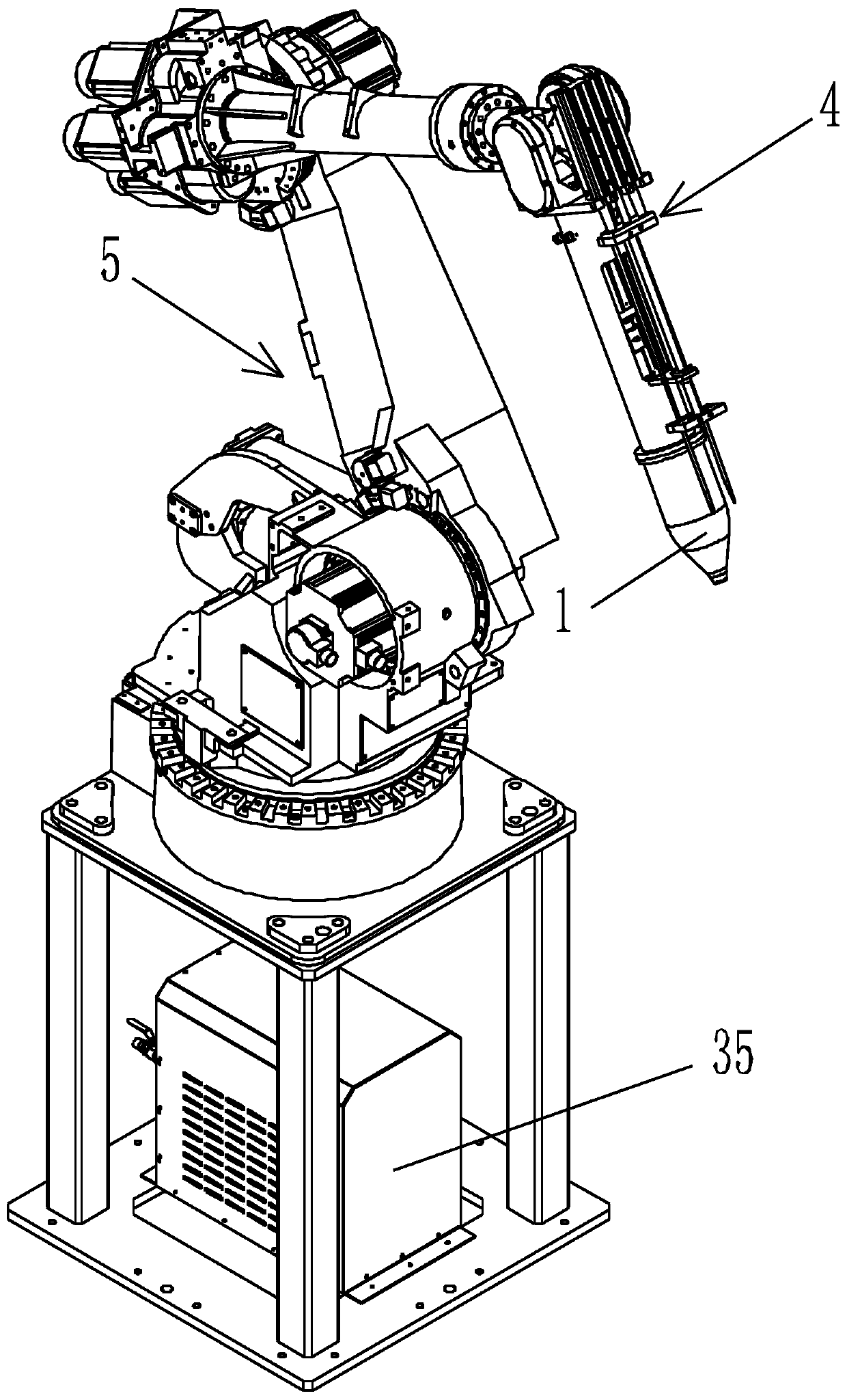

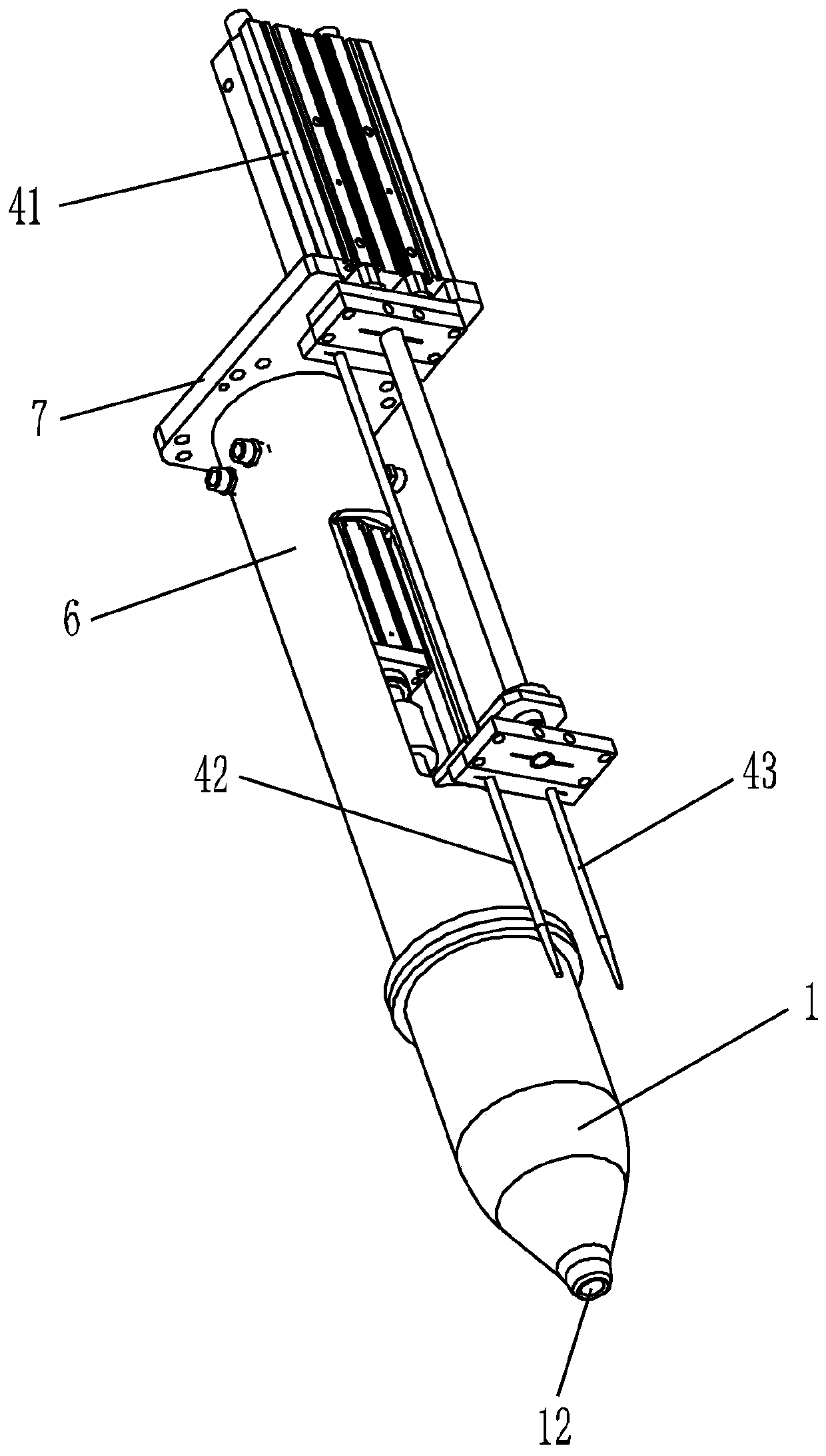

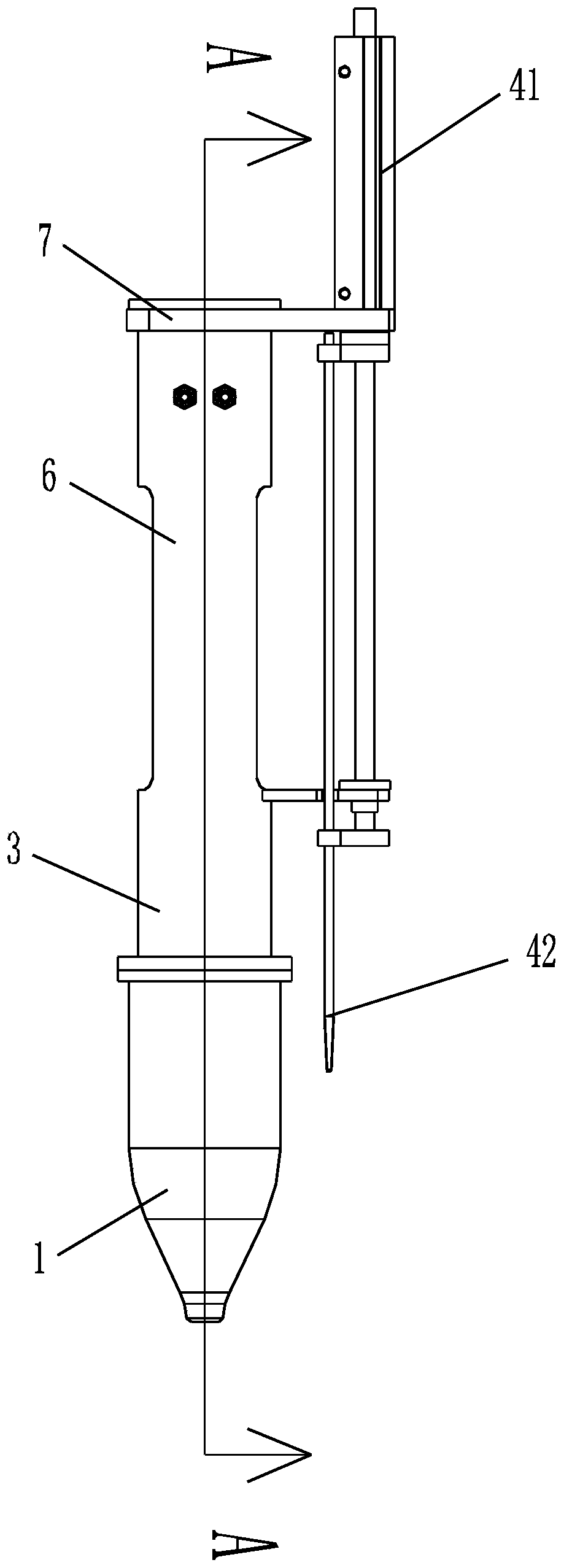

[0021] like Figure 1 to Figure 6 Shown is a schematic diagram of an embodiment of a self-priming soup dispenser provided by the present invention.

[0022] A self-priming soup dispensing machine comprises a suction and injection device and a transfer device that drives the suction and injection device to move.

[0023] The pouring device includes a pouring tank 1 and a plugging assembly; the pouring tank 1 is provided with a pouring chamber 11 containing molten metal, and the lower end of the pouring tank 1 is provided with a suction hole 12 communicating with the pouring chamber 11; The pouring cavity 11 is provided with an exhaust channel 13 communicating with the outside world; the sealing assembly includes a sealing head 21 for opening and closing the suction hole 12 .

[0024] When the suction device is runnin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com