Liquid delivery device based on centrifugal force

A conveying device and centrifugal force technology, applied in the field of centrifugal force-based liquid conveying devices, can solve the problems of inconvenient testing, inaccurate operation, and complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

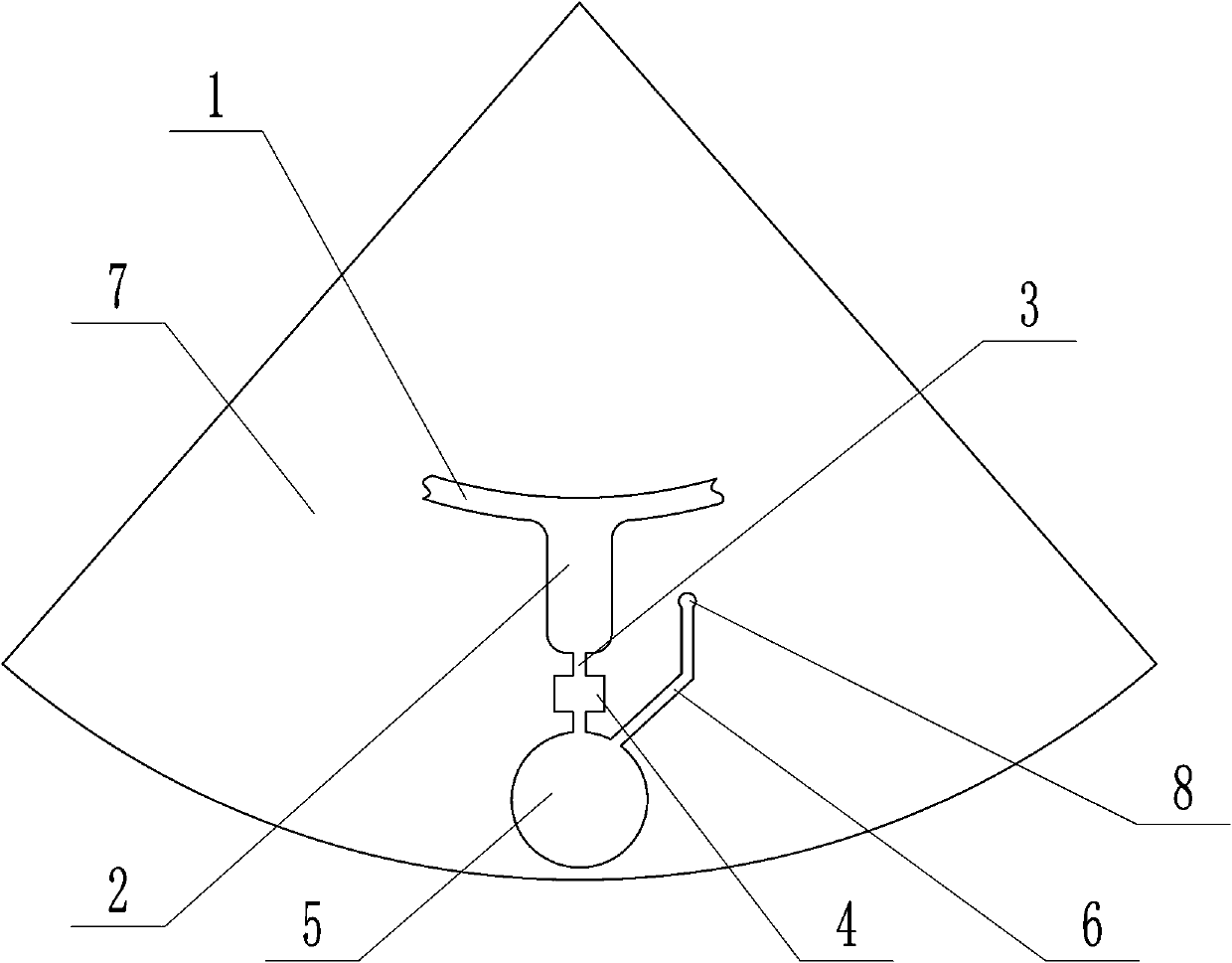

[0012] Example 1: as attached figure 1 As shown, the present invention includes a rotating reagent disk 7, a first chamber 2 arranged on the rotating reagent disk 7, a second chamber 5 communicating with the first chamber 2 through the first flow channel 3, and a variable device arranged on the first flow channel 3. A diameter chamber 4, the inner diameter of the variable diameter chamber 4 is larger than the inner diameter of the first flow channel 3, and the variable diameter chamber 4 cooperates with the first flow channel 3 to form a capillary passive valve. The first chamber 2 , the first flow channel 3 and the second chamber 5 are disposed outward in order relative to the rotation axis. The inner diameter of the lightening chamber 4 suddenly becomes larger relative to the chamber of the first flow channel 3, so that a capillary passive valve is formed in the first flow channel 3. When the rotation speed of the rotating reagent disk 7 is low, due to the action of the capi...

Embodiment 2

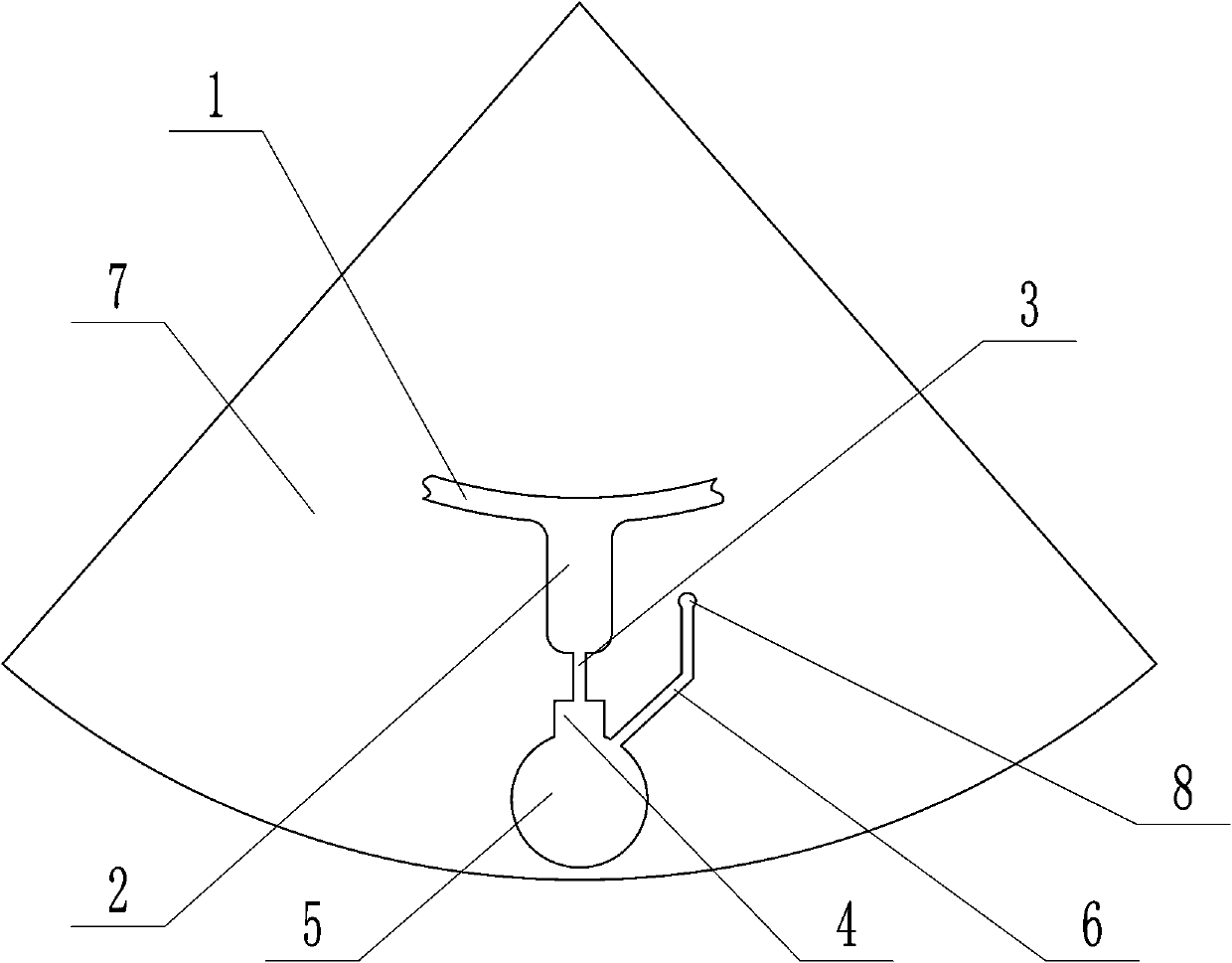

[0016] Example 2: as attached figure 2 As shown, on the basis of Embodiment 1, other structures are kept unchanged, and only the position of the variable diameter chamber 4 is changed, so that the variable diameter chamber 4 and the second chamber 5 are connected to form a chamber, and the embodiment can also be realized. 1 effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com