Nano 3D printing process

A printing process and nano technology, applied in the field of nano 3D printing process, can solve the problems of high post-processing cost, high water and heat source consumption, limited detail and accuracy of printing patterns, etc., to ensure safety and simplify the process. , to avoid the effect of sewage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

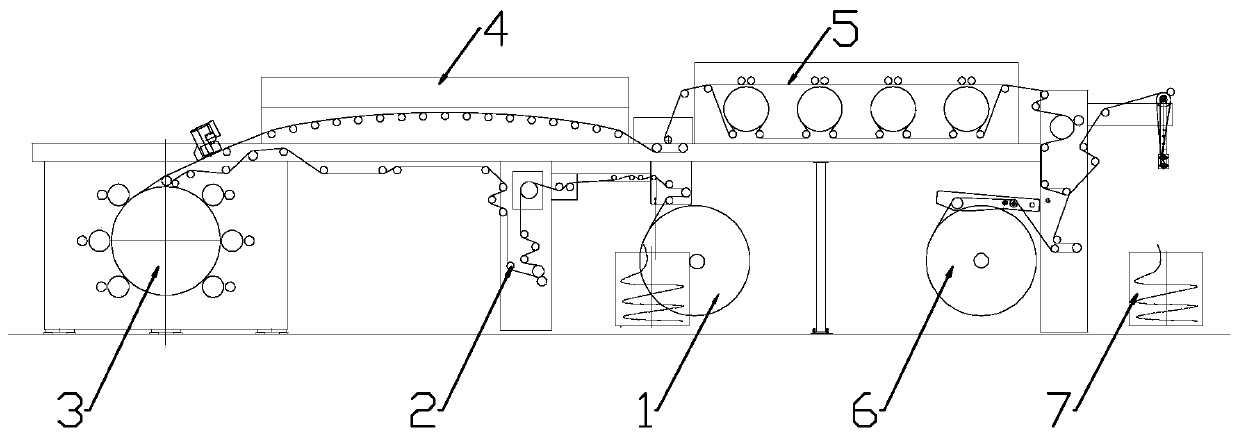

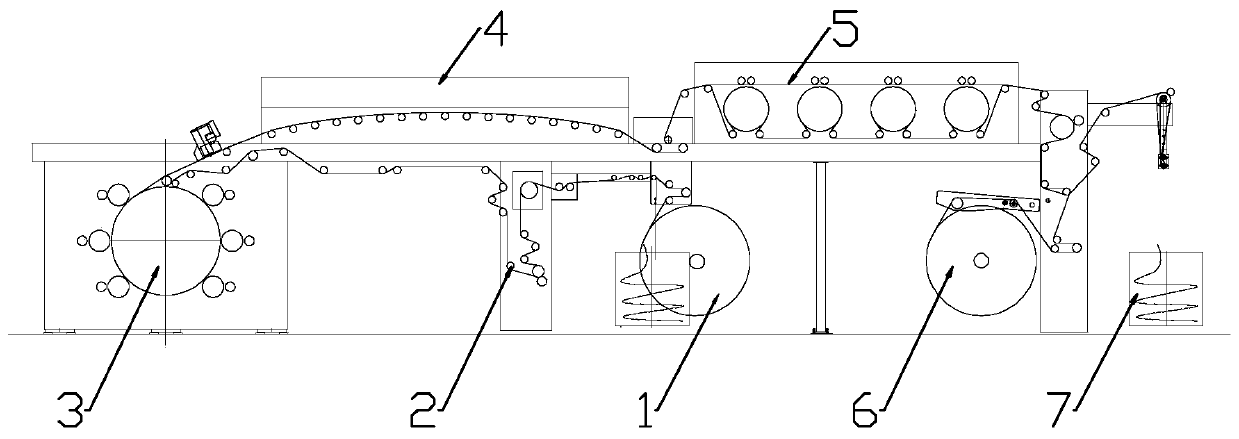

[0024] In this embodiment, the nanometer 3D printing process combines figure 1 , including the following steps:

[0025] (1) Gray cloth finishing: Clean the gray cloth to remove obvious stains, and set it aside.

[0026] (2) Ink preparation: The ink is composed of dyes, dispersing additives and water.

[0027] The nano-ink formed by the above preparation is placed in the ink cartridge of the printing machine in the printing section 3 for use.

[0028] (3) Send the gray cloth of step (1) into the discharge part 1, and under the influence of each traction roller of the discharge traction part 2, the gray cloth is sent to the printing part 3. In the printing part 3, the number of screen lines is 55-175LPI , the speed of the printing machine is 80-200m / min, the printing temperature is 180-230°C, and the pressure is 1-2um. The nano-holes (inking holes) on the anilox roller 31 transfer the ink quantitatively to the passing gray cloth. After the transfer is completed, send it to T...

Embodiment 2

[0030] The setting and working principle of this embodiment are the same as those of Embodiment 1, the difference is that the printing process is different, and the parameters of the printing process are compared as shown in Table 1.

[0031] Table 1 Comparison table of parameters of different printing processes

[0032] serial number Edition line number LPI Machine speed, m / min Printing temperature, ℃ pressure, 1 55 50-80 180-185 1-2um 2 65 50-100 180-190 1-2um 3 80 60-100 185-200 1-2um 4 100 80-120 190-210 1-2um 5 120 100-150 200-215 1-2um 6 175 100-200 200-230 1-2um

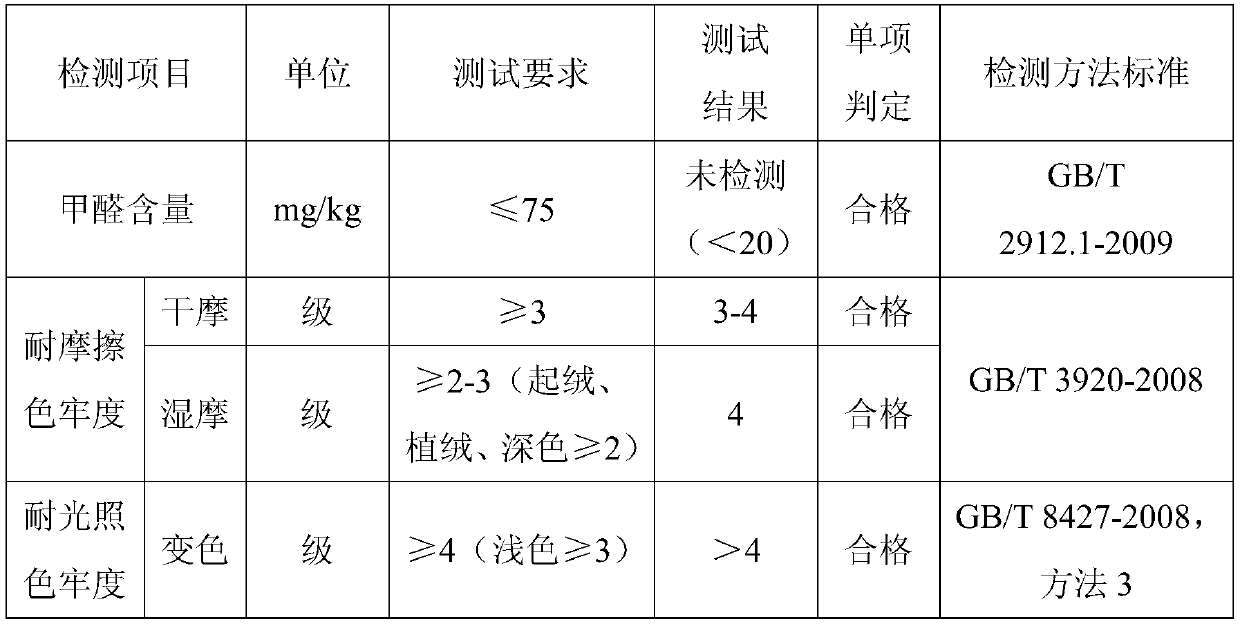

[0033] Printed Fabric Inspection

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com