Three-dimensional buffering method

A buffer method and three-dimensional technology, applied in the field of buffering, can solve problems such as incoordination, waiting for the next process line, and affecting the operation efficiency of the production line, so as to achieve the effect of improving operation efficiency and solving the phenomenon of incoordination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

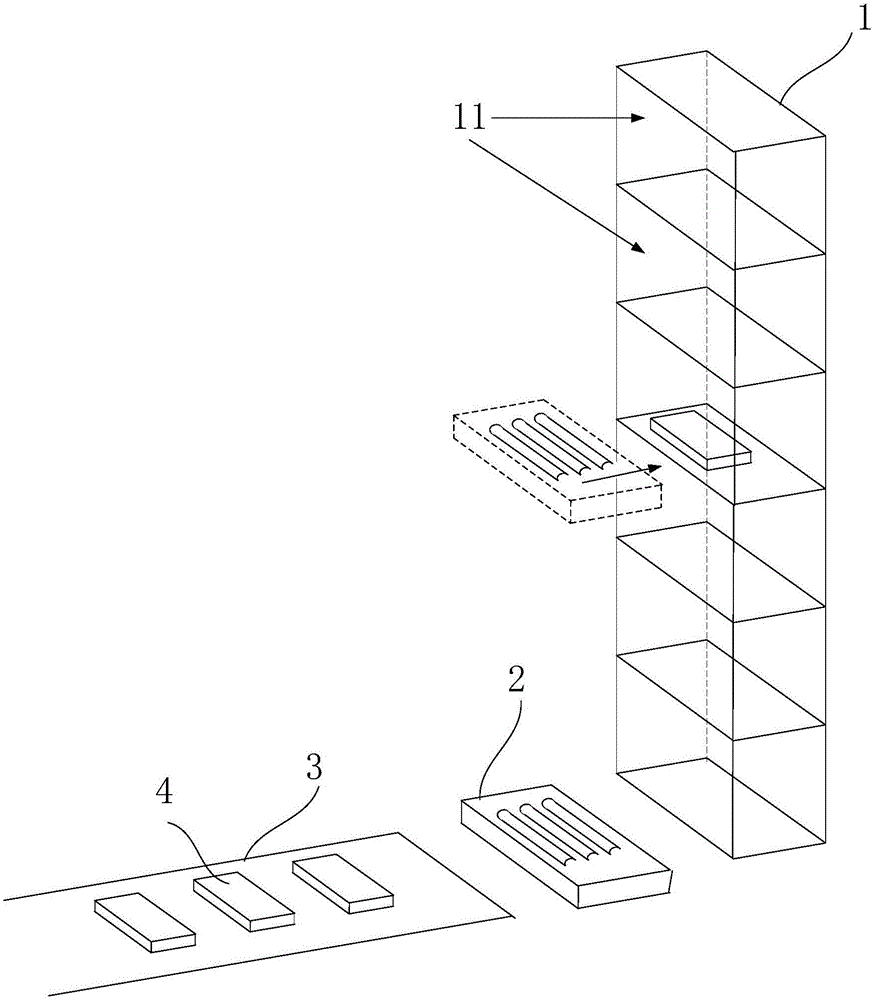

[0028] Such as Figure 1 to Figure 3 As shown, it is a schematic structural view of the three-dimensional cushioning device in Embodiment 1 of the present invention, and the three-dimensional cushioning device includes:

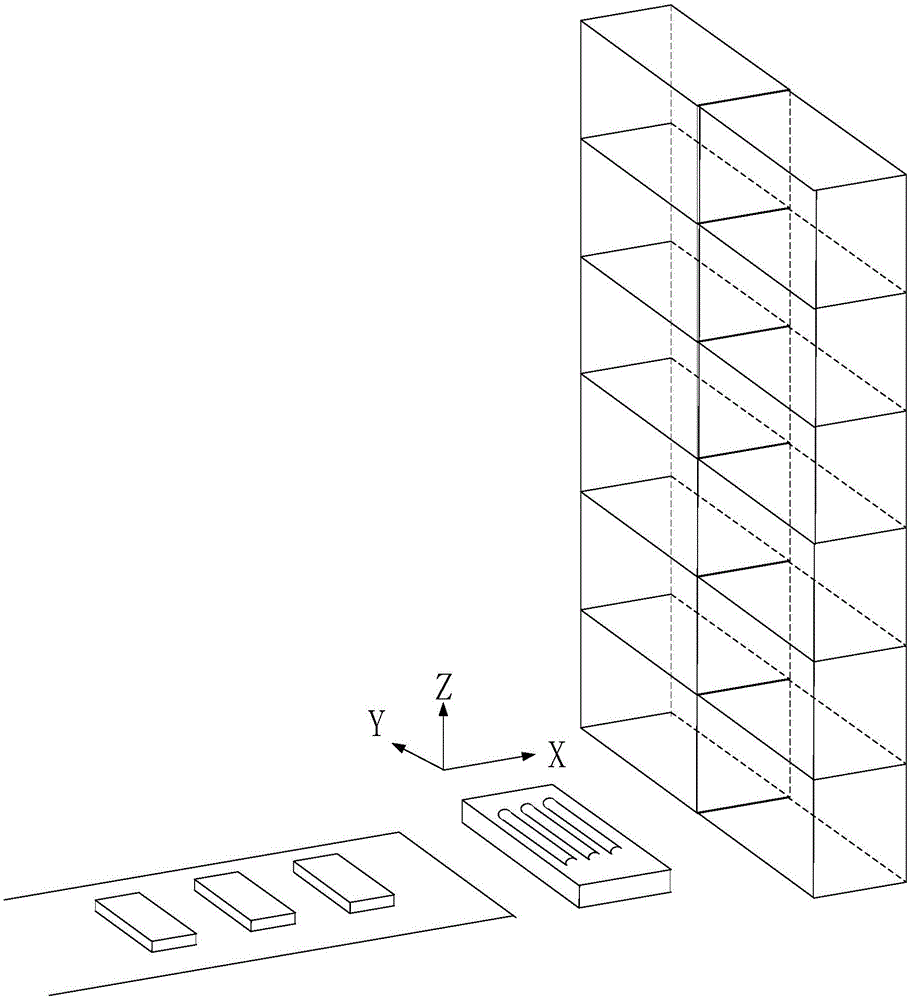

[0029] The three-dimensional storage device 1 includes a plurality of workpiece storage units 11 for storing workpieces. Among them, the three-dimensional storage device can be such as figure 1 The one shown is composed of multi-layer grid-shaped storage spaces arranged vertically, and each layer is provided with a workpiece storage unit. In addition, the workpiece storage unit 11 can also be figure 2 The one shown in is composed of a multi-layer structure, and there are a plurality of workpiece storage units 11 in the horizontal direction on each layer. Each workpiece storage unit can store one or more workpieces 4 , and the shape of the workpieces is not limited, as long as it can be put into the workpiece storage unit 11 .

[0030] The bridging part 2 ...

Embodiment 2

[0036] Such as Figure 4 As shown, it is a schematic structural diagram of the three-dimensional buffer device in Embodiment 2 of the present invention. In this embodiment, the workpiece storage unit 11 is a front-to-back through structure, and the three-dimensional buffer device is arranged on the first process line 31 and the second process line 32. In between, the three-dimensional buffer device is docked with the first process line 31 and the second process line 32 .

[0037] The bridging portion includes a first bridging portion 21 arranged on the inlet side of the three-dimensional storage device 1 and a second bridging portion 22 arranged on the outlet side of the three-dimensional storage device, the first bridging portion 21 is used to receive The workpiece of the first process line 31 is stored in the workpiece storage unit of the three-dimensional storage device, and the second bridging part 22 is used to extract the workpiece from the workpiece storage unit 11 of t...

Embodiment 3

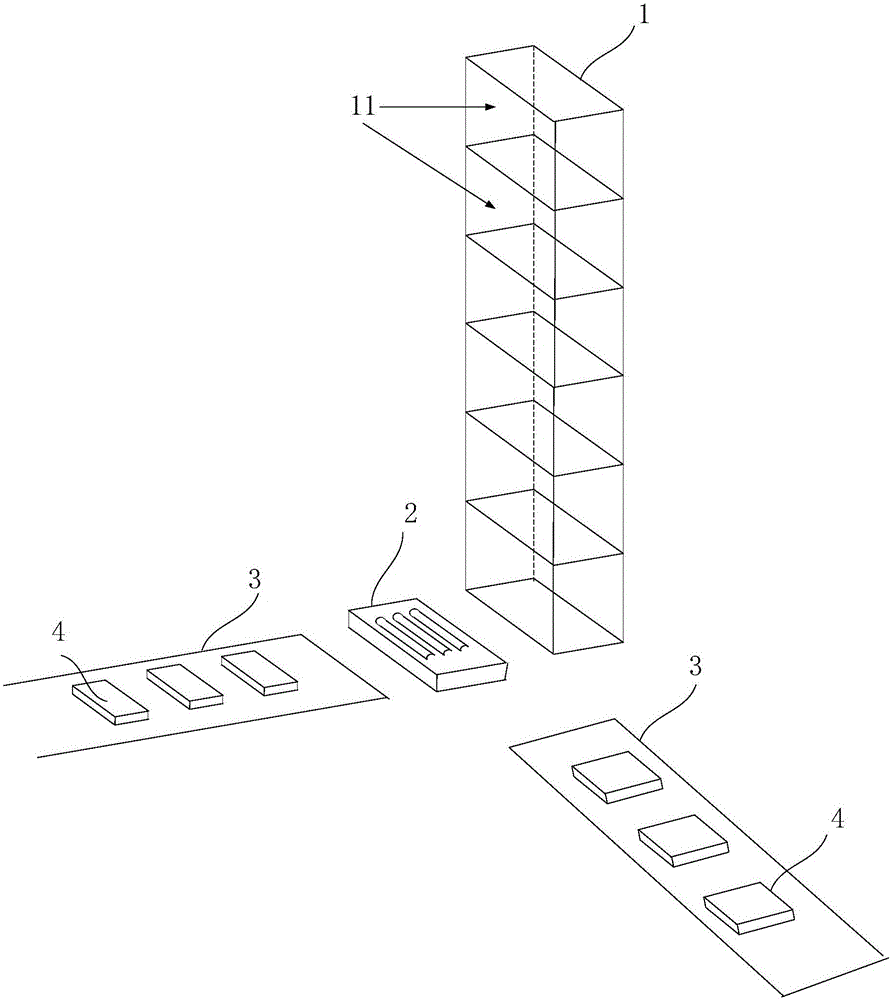

[0040] Such as Figure 5 As shown, it is a schematic diagram of the three-dimensional structure of the three-dimensional cushioning device according to the third embodiment of the present invention. , wherein, there is at least one bridging portion 2 for receiving the workpiece of a designated process line 3 and depositing the workpiece into the workpiece storage unit 11 of the three-dimensional storage device 1, there is at least one bridging portion 2 for receiving the workpiece from the three-dimensional storage device 1 The workpiece storage unit 11 picks up workpieces and transfers them to another designated process line 3 . As shown in the figure, the three-dimensional buffer device of this embodiment can provide a buffer mechanism for workpiece processing for multiple process lines, and through the coordinated processing of at least two bridging parts, storage and processing are performed between the three-dimensional storage device and each process line. The operation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com