Single-hand rapid-disengaging chuck

A technology of clipping and mandrel, applied in the directions of wrenches, screwdrivers, manufacturing tools, etc., can solve the problems of broken screwdriver heads, smashed people and objects, inconvenient use, etc., so as to reduce the number of times of falling and picking up, and reducing the number of times of use. , easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

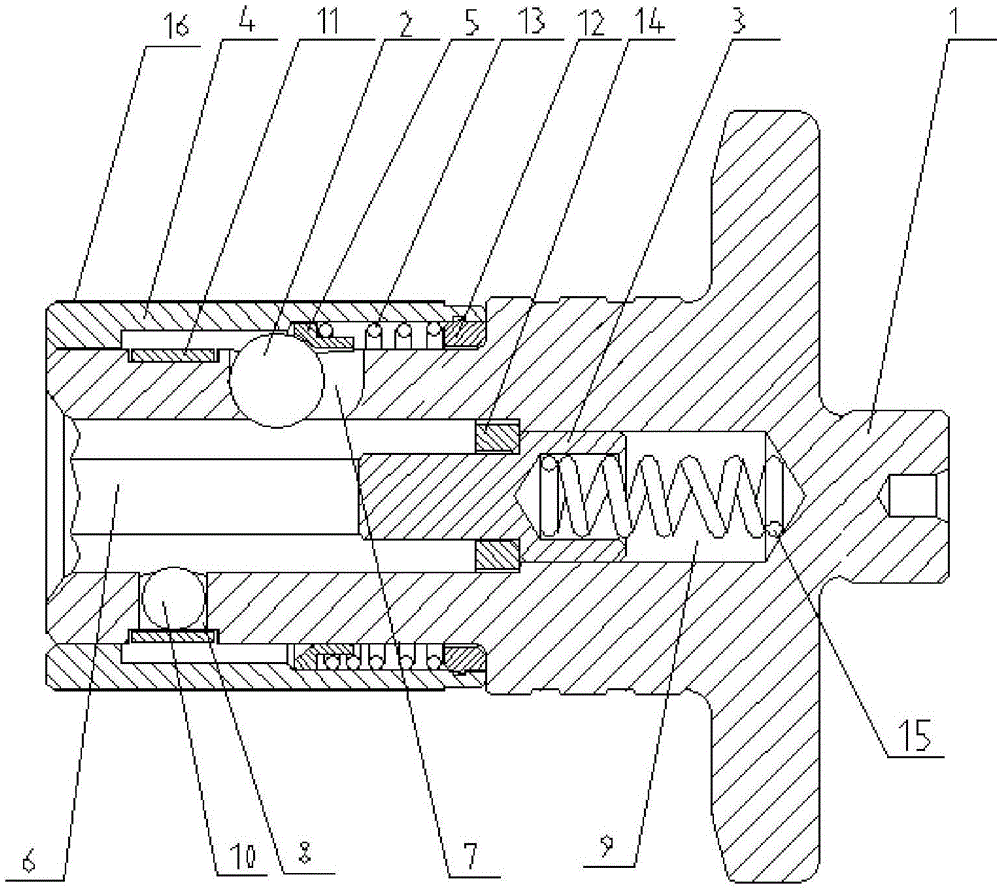

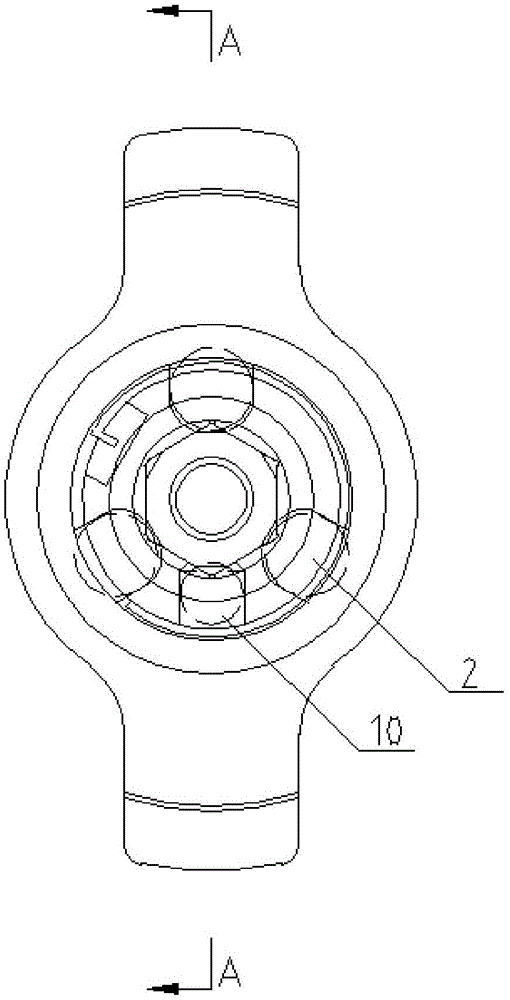

[0018] Embodiment: A one-handed quick-release chuck, including a mandrel 1, a sphere 2, a sliding pin 3, a jacket 4, a retaining ring 5 and an abutting member, and one end of the mandrel 1 forms an axial non-circular insert The slot 6, the mandrel 1 is located on the side wall of the slot 6 and is provided with at least one elongated radial perforation 7 extending in the axial direction and at least one radial groove 8, and the bottom surface of the slot 6 is recessed to form a circular Groove 9, the ball 2 can be slid and accommodated in the radial perforation 7 of the mandrel 1 along the extension direction of the radial perforation 7, the sphere 2 can be partially exposed into the slot 6, and the sphere 2 cannot completely fall into the slot 6 , the pressing piece is positioned in the radial groove 8 of the mandrel 1, one end of the pressing piece elastically protrudes into the slot 6, and the pressing piece will not completely fall into the slot 6, the sliding pin 3 axis I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com