Bionic dry adhesion mechanism based on loading of composite constant-force spring

A technology of constant force spring and loading mechanism, which is applied in the direction of motor vehicles, space navigation equipment, space navigation aircraft, etc., can solve the problem of different shapes and sizes of space debris, and achieve good robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

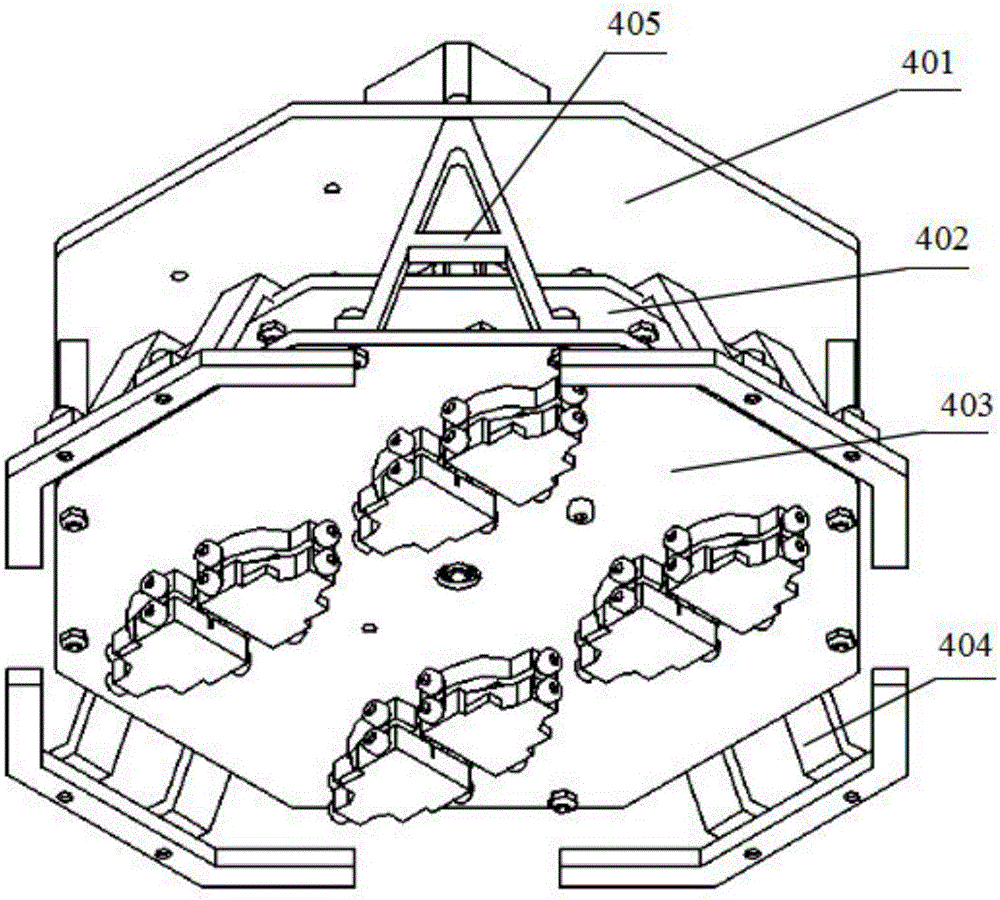

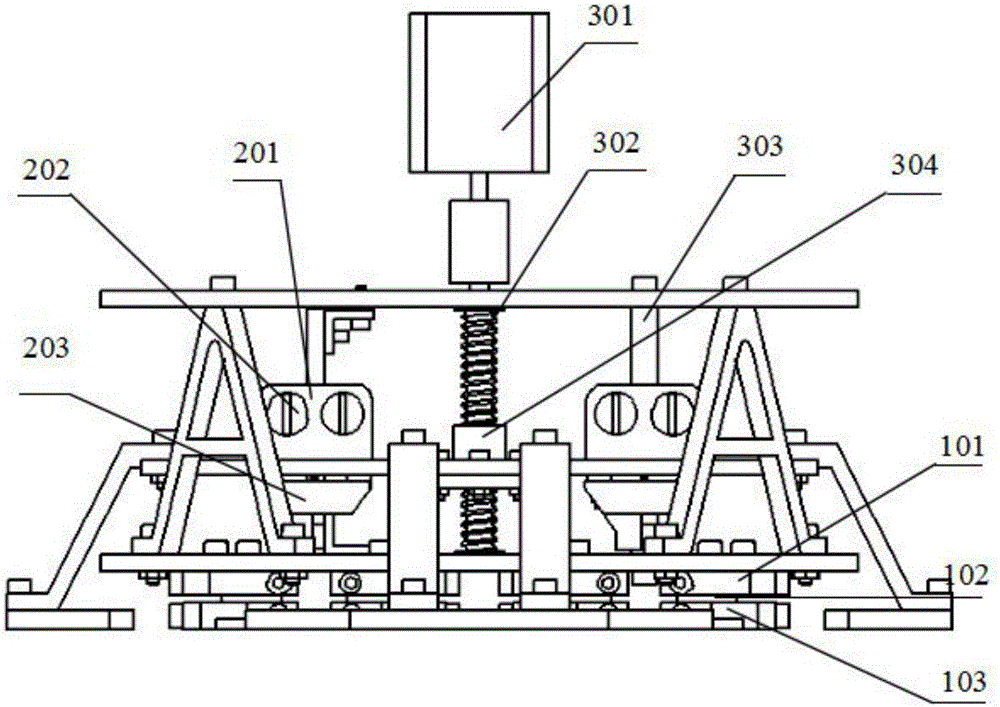

[0031] Such as Figure 1a with Figure 1b As shown, it is a three-dimensional bottom view and a side view of the space debris cleaning bionic dry adhesion mechanism of the present invention, including: adhesion foot unit, composite constant force spring loading mechanism, motor and transmission mechanism, and mechanism frame.

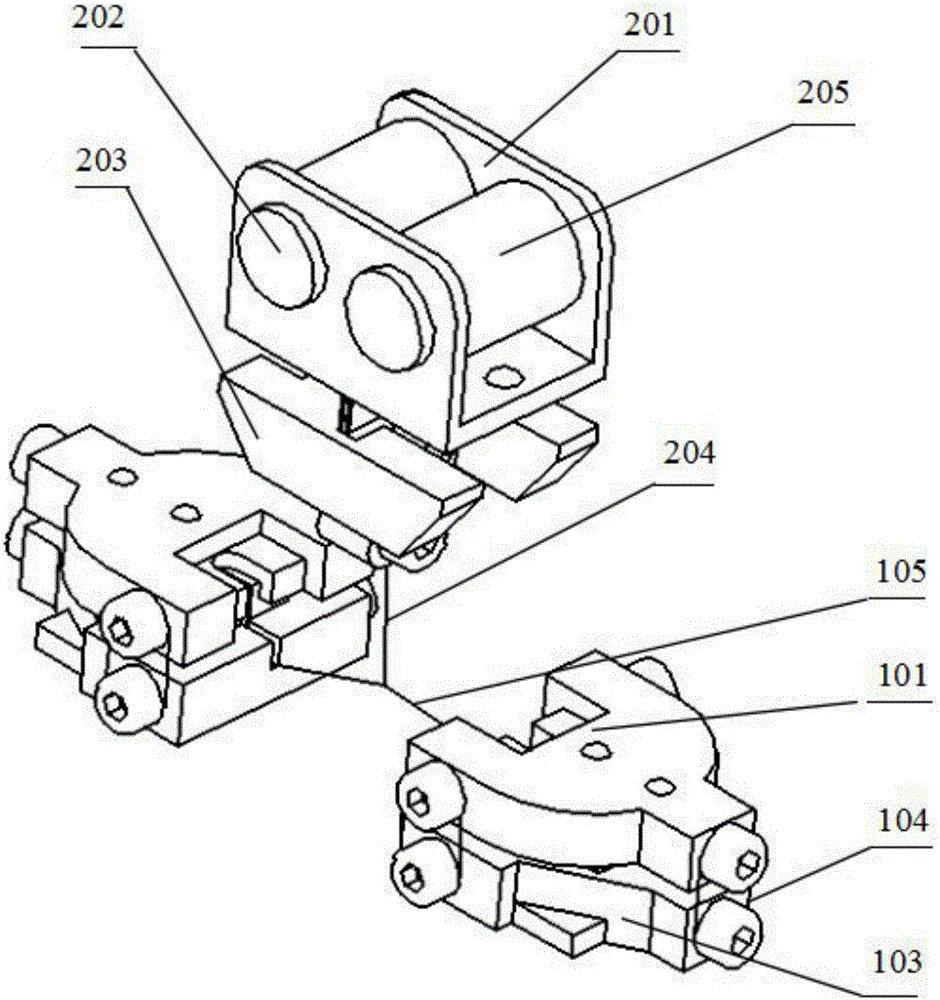

[0032]The sticky sole unit is composed of two sticky soles with left-right symmetry and the same shape, and each sole includes: an upper support plate 101, a flexible support material 102, a lower support plate 103, a nylon limit ring 104, and a horizontal connecting tendon 105; The composite constant force spring loading mechanism includes: U-shaped bracket 201, cylindrical pin 202, wedge block 203, vertical loading tendon 204, composite constant force spring 205; the motor and transmission mechanism include: motor 301, screw rod 302, nut 304 , guide rail slider 303 ; the mechanism frame 4 includes: a top plate 401 , a middle plate 402 , a bottom plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com