Protective greening structure for rock or concrete high and steep slope and construction method of protective greening structure

A technology for high and steep slopes and protective structures, applied in infrastructure engineering, botanical equipment and methods, excavation, etc., can solve problems such as long construction period, poor water retention performance, and complex construction, so as to achieve simple construction and avoid instability , Reduce the effect of climbing height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

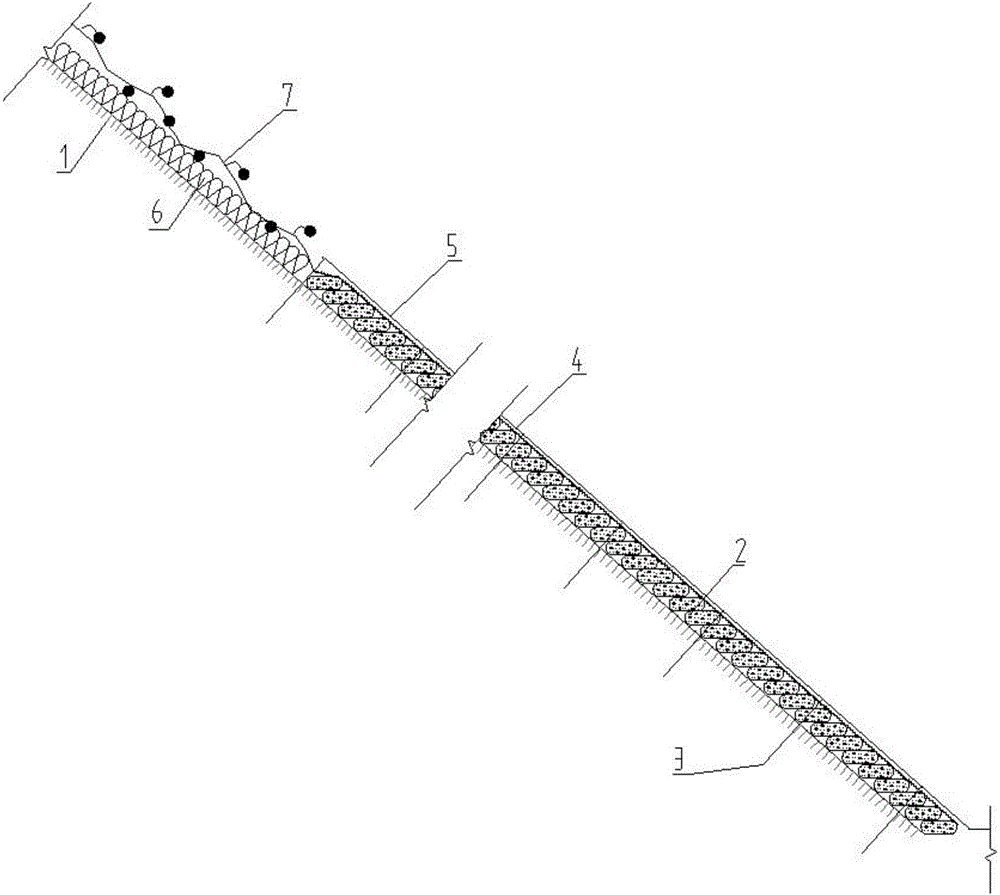

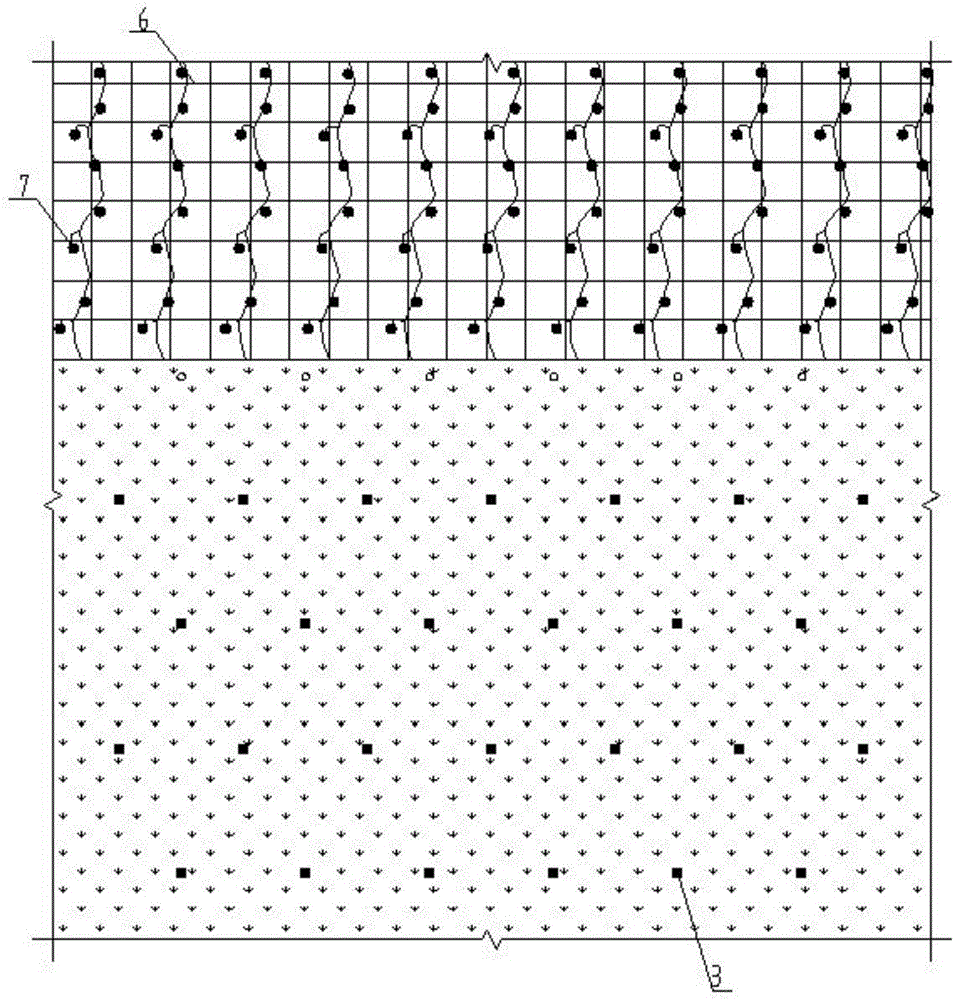

[0037] Build drainage ditches at the bottom of side slope 1 and clean up side slope 1; open holes in the lower part of side slope 1, and lay anchor rods 3 in the holes. The anchor rods 3 are arranged in a plum blossom shape. Cylindrical with a diameter of 16mm, the depth of the anchor rod 3 inserted into the slope 1 is 65cm, and the distance between the anchor rods 3 is 100cm; a number of ecological bags 2 are placed in the lower part of the slope 1, the length of the ecological bag 2 is 65cm, and the width is 30cm, 15cm in height, the planting soil mixed with compound fertilizer is filled in the ecological bag 2, and the ecological bag 2 is stacked upwards from the bottom of the slope 1 in a step-like shape, and forms a planting platform; hang a galvanized wire mesh on the anchor rod 3 4. The diameter of the galvanized wire mesh 4 is 5cm×5cm, the diameter of a single wire is 2mm, the galvanized wire mesh 4 and the ecological bag 2 offset, the overlapping length of the galvaniz...

Embodiment 2

[0039]Build drainage ditches at the bottom of side slope 1 and clean up side slope 1; open holes in the lower part of side slope 1, and lay anchor rods 3 in the holes. The anchor rods 3 are arranged in a plum blossom shape. Cylindrical with a diameter of 16mm, the depth of the anchor rod 3 inserted into the slope 1 is 60cm, and the distance between the anchor rods 3 is 100cm; a number of ecological bags 2 are stacked in the lower part of the slope 1, the length of the ecological bag 2 is 65cm, and the width is 30cm, height is 15cm, the planting soil mixed with compound fertilizer is filled in the ecological bag 2, and the ecological bag 2 is stacked up stepwise from the bottom of the slope 1 to form a planting platform; hang galvanized wire mesh 4 on the anchor rod 3 , the diameter of the galvanized wire mesh 4 is 5cm×5cm, the diameter of a single wire is 2mm, the galvanized wire mesh 4 offsets the ecological bag 2, the overlapping length of the galvanized wire mesh 4 is 110cm,...

Embodiment 3

[0041] Build drainage ditches at the bottom of side slope 1 and clean up side slope 1; open holes in the lower part of side slope 1, and lay anchor rods 3 in the holes. The anchor rods 3 are arranged in a plum blossom shape. Cylindrical with a diameter of 16mm, the depth of the anchor rod 3 inserted into the slope 1 is 62cm, and the distance between the anchor rods 3 is 100cm; a number of ecological bags 2 are stacked in the lower part of the slope 1, the length of the ecological bag 2 is 65cm, and the width is 30cm, height is 15cm, the planting soil mixed with compound fertilizer is filled in the ecological bag 2, and the ecological bag 2 is stacked up stepwise from the bottom of the slope 1 to form a planting platform; hang galvanized wire mesh 4 on the anchor rod 3 , the diameter of the galvanized wire mesh 4 is 5cm×5cm, the diameter of a single iron wire is 2mm, the galvanized wire mesh 4 and the ecological bag 2 offset, the overlapping length of the galvanized wire mesh 4 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com