A display panel, its manufacturing method and display device

A technology for a display panel and a display device, applied in the field of display panel, display device and their preparation, can solve the problems of uneven film thickness of the light-emitting layer, affecting the display effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

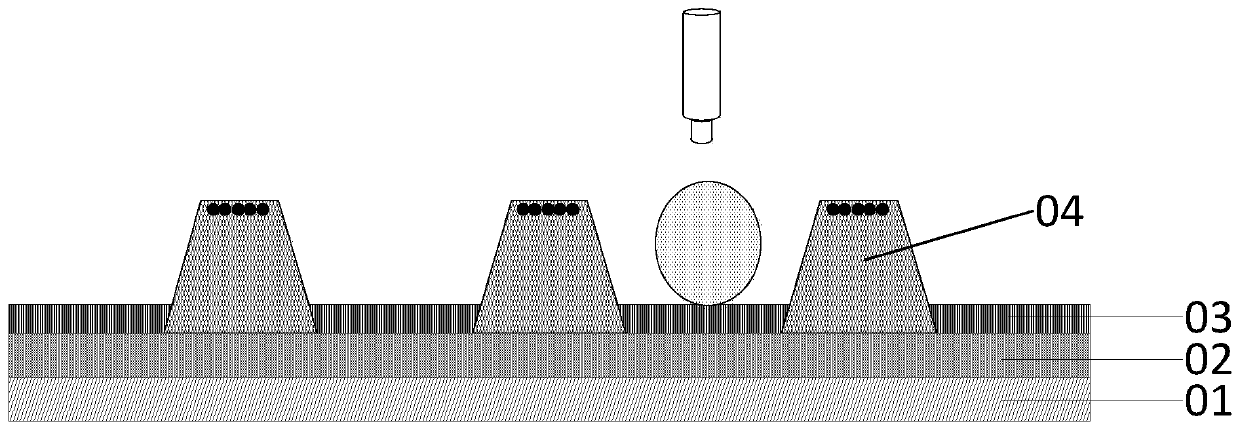

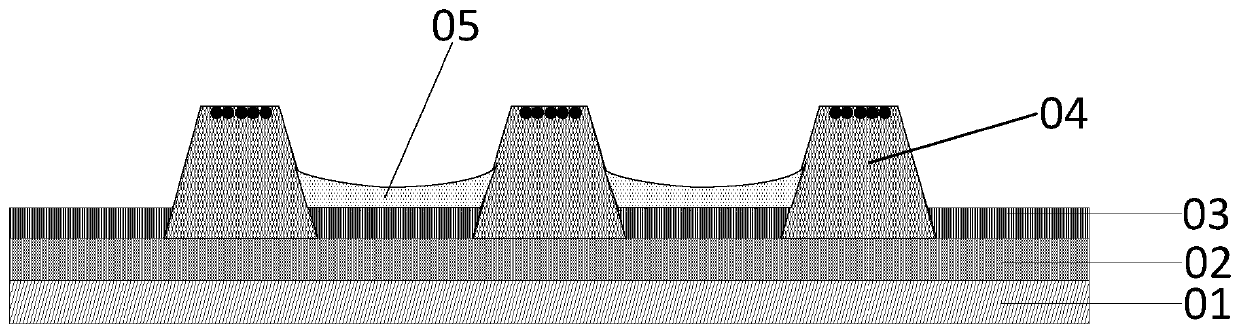

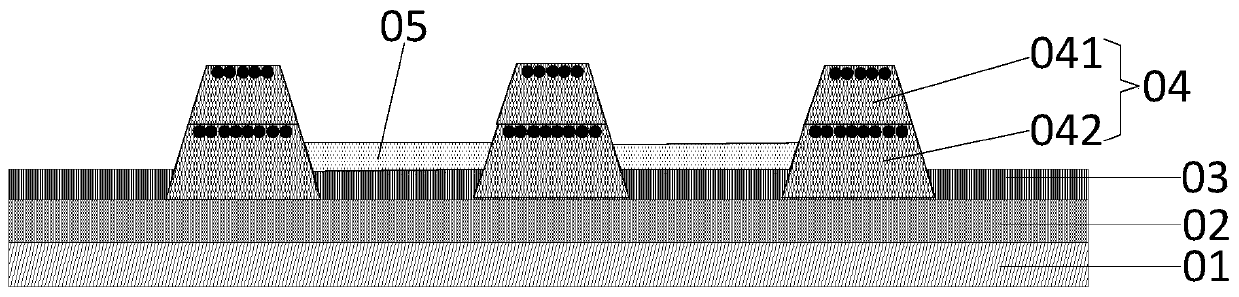

[0050] Based on the same inventive concept, an embodiment of the present invention also provides a method for manufacturing a display panel, such as Figure 4 shown, including:

[0051] S401, forming a pattern of a plurality of anodes arranged in a matrix on the base substrate;

[0052] S402, forming a pattern of a first pixel defining layer between each anode on the base substrate formed with each anode; wherein the upper surface of the first pixel defining layer has liquid repellency;

[0053] S403, forming a pattern of a second pixel defining layer on a side of the first pixel defining layer facing away from the base substrate; wherein the upper surface of the second pixel defining layer has liquid repellency.

[0054] The above-mentioned display panel manufacturing method provided by the embodiment of the present invention divides the existing pixel defining layer into two layers, that is, the pixel defining layer includes a first pixel defining layer and a second pixel d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com