Three-way oil fume separation device of integrated cooker

A technology of oil fume separation and integrated stoves, which is applied in the field of integrated stoves, and can solve problems such as easy fires, environmental sanitation, and odors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

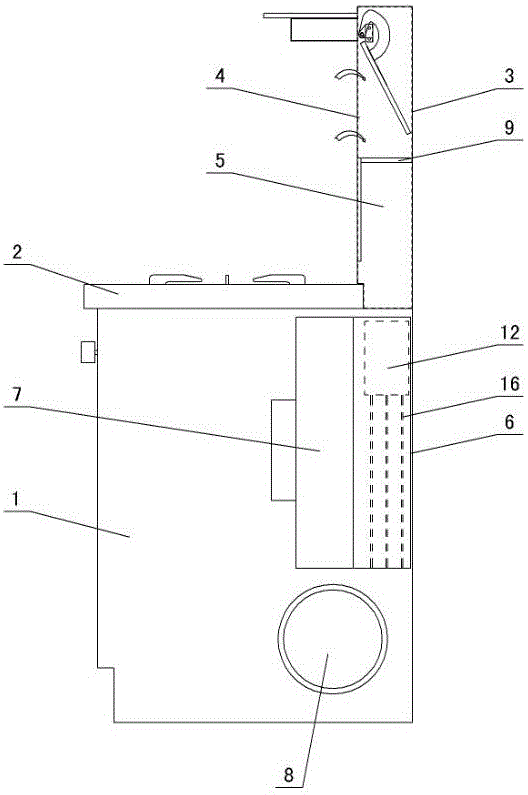

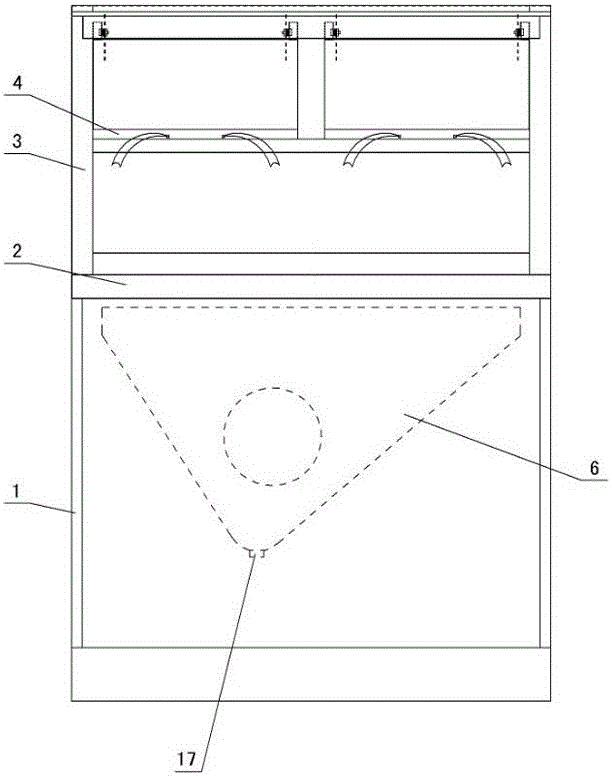

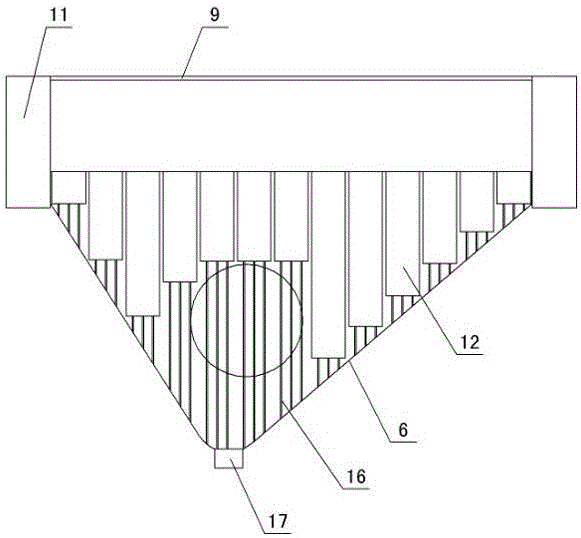

[0013] The invention relates to a three-channel oil fume separation device for an integrated stove, such as figure 1 — Image 6 As shown, it includes a box body 1, a stove 2 is arranged on the box body, a side suction plate 3 is arranged on the stove top, a side suction hole 4 is formed on the wall of the side suction plate, and a suction channel 5 is opened in the side suction plate , the smoke collection box 6 and the wind wheel 7 are arranged in the box, the side outlet of the smoke collection box is connected to the wind wheel, and the wind wheel is connected to the air outlet 8, and it is characterized in that: the suction channel 5 located at the side suction hole 4 Install a mesh plate 9 with a separation mesh 10 in the mesh plate, oil collecting boxes 11 are arranged on both sides of the mesh plate, 10-20 vortex cyclone tubes 12 are arranged side by side in the smoke collecting box 6, and the middle part of the vortex cyclone tube is a through hole 13. The inner wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com