An electric powder spraying device

A power supply device and powder spraying technology, which is applied in the device, application, animal husbandry and other directions of catching or killing insects to achieve the effect of uniform distribution and continuous concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

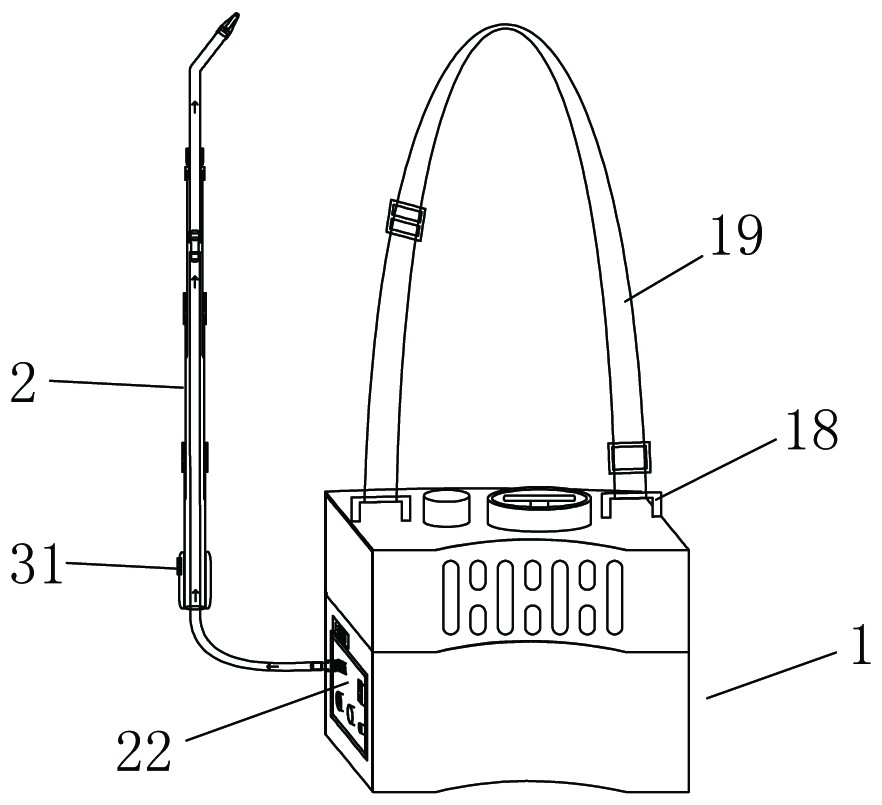

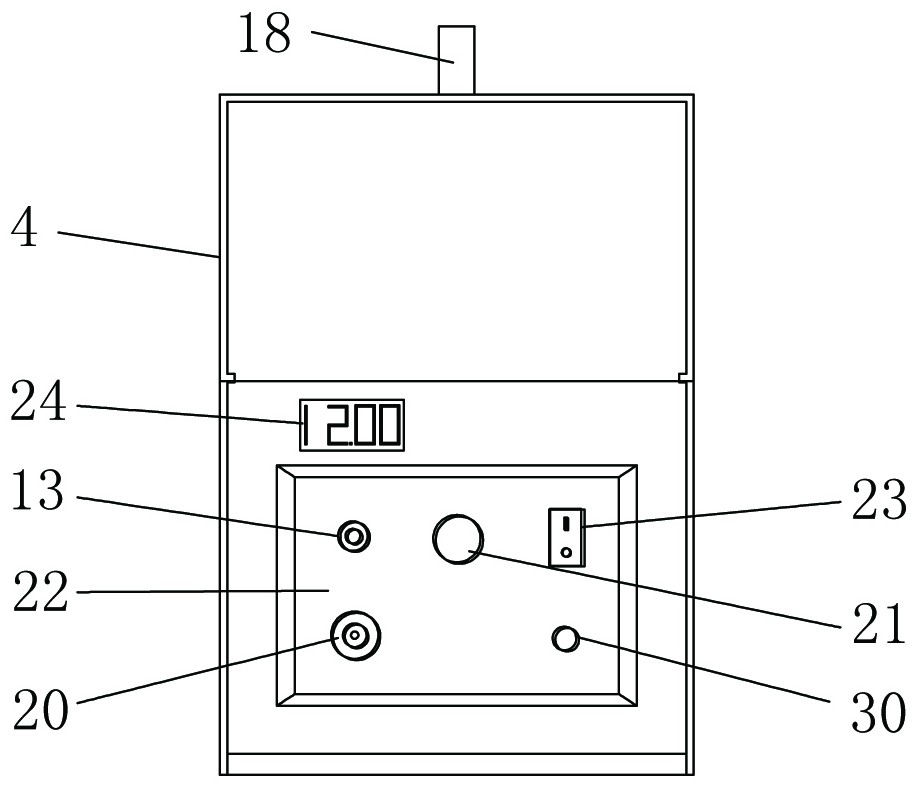

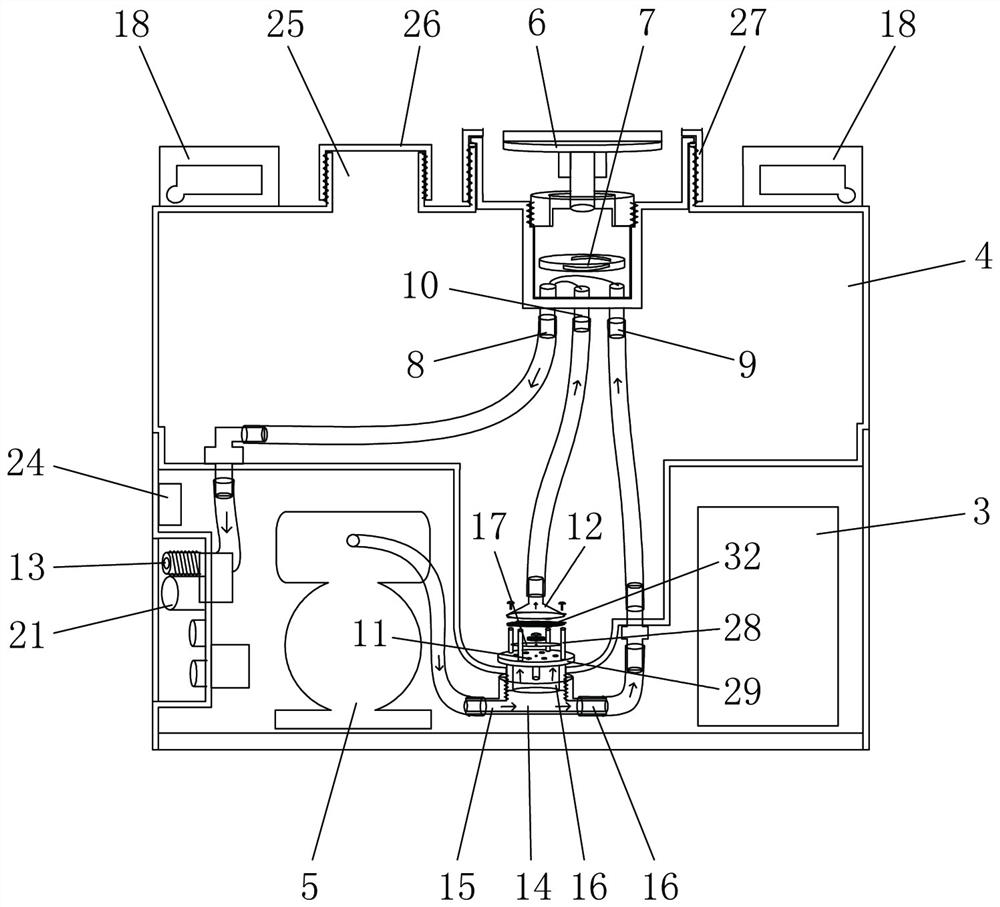

[0019] refer to Figure 1 to Figure 4 , an electric powder spraying device, including a main engine 1 and a discharging rod 2, the main engine 1 includes a controller, a power supply device 3, a powder bin 4 and an air supply device 5, and the main engine 1 is also provided with an adjustment handle 6. Proportional valve 7; the proportional valve 7 is provided with a powder outlet 8, a proportional valve air inlet 9 and a powder inlet 10; the lower part of the powder bin 4 is provided with a through hole; the upper part of the through hole is provided with a powder suction The cover 12, the proportional valve air inlet 9 and the through hole are connected with the air supply device 5 through a hose, the powder suction cover 12 is connected with the powder inlet 10 through a hose, and the powder outlet 8 It is connected with the discharge pipe joint 13 arranged on the side wall of the main machine 1 through a hose, and the discharge rod 2 is connected with the discharge pipe jo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com