Method and apparatus for supplying hydrogen selenide mixed gas for solar cell

A technology of solar cells and mixed gases, applied in binary selenium/tellurium compounds, photovoltaic power generation, climate sustainability, etc., can solve the problem that flow control is no longer effective, gas supply cannot be guaranteed, and the frequency of replacement of gas storage cylinders is increasing, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

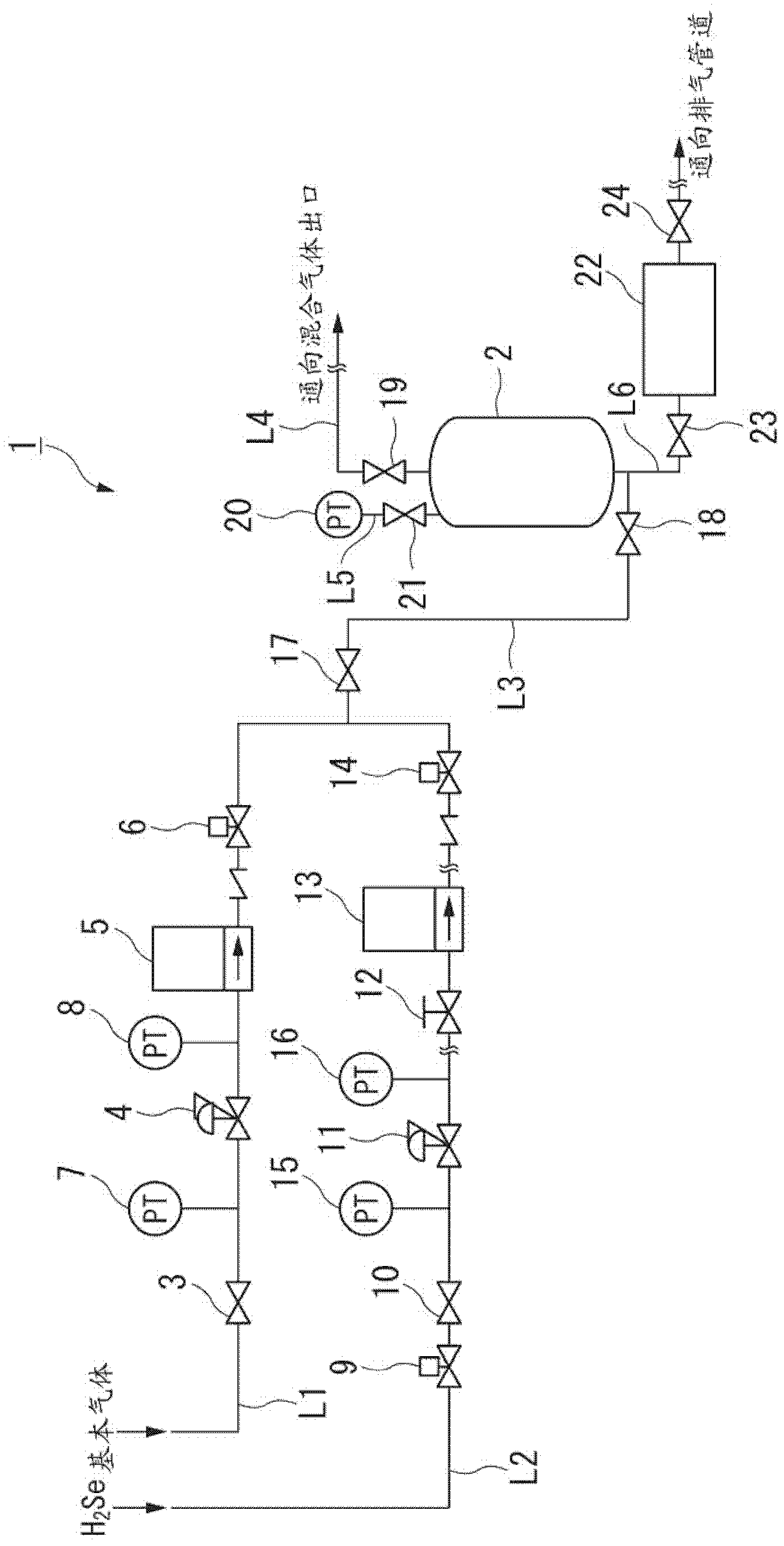

[0087] use figure 1 The shown supply device 1 continuously supplies hydrogen-selenide mixed gas to a solar cell manufacturing device. When continuously supplying the hydrogen-selenide mixed gas to the solar cell manufacturing apparatus, a batch process method using the buffer tank 2 was adopted.

[0088] In addition, the conditions of Table 1 were used as conditions at the time of supplying hydrogen-selenide mixed gas by the supply apparatus 1.

[0089] After performing 50 batch processes according to the conditions in Table 1, use the gas concentration analyzer 22 connected to the buffer container 2 to record the concentration change of the mixed gas. Table 2 shows the results.

example 2

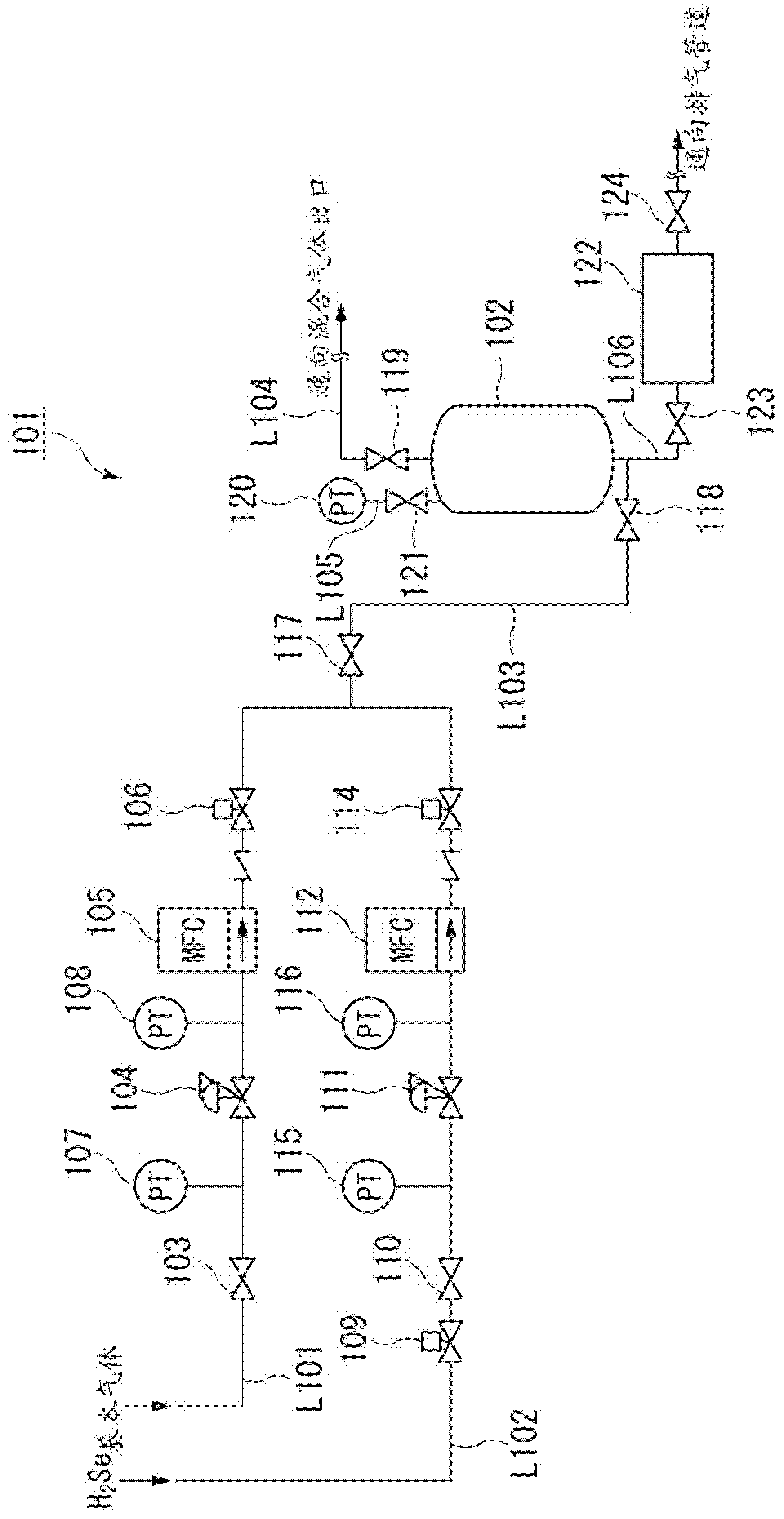

[0091] use figure 2 The shown supply device 101 continuously supplies hydrogen-selenide mixed gas to a solar cell manufacturing device. When continuously supplying the hydrogen-selenide mixed gas to the solar cell manufacturing apparatus, a batch method using the buffer tank 102 was adopted, and the conditions in Table 1 were used as the conditions for supplying the hydrogen-selenide mixed gas from the supply device 101 .

[0092] After performing 50 batch processes according to the conditions in Table 1, use the gas concentration analyzer 122 connected to the buffer container 102 to record the concentration change of the mixed gas. Table 2 shows the results.

[0093]

[0094] Table 1

[0095]

example 1

Example 2

Set concentration [%]

10.00

10.00

Measured concentration after 50 batches [%]

10.10

11.31

Concentration change [%]

+0.10

+1.31

[0096] Table 2

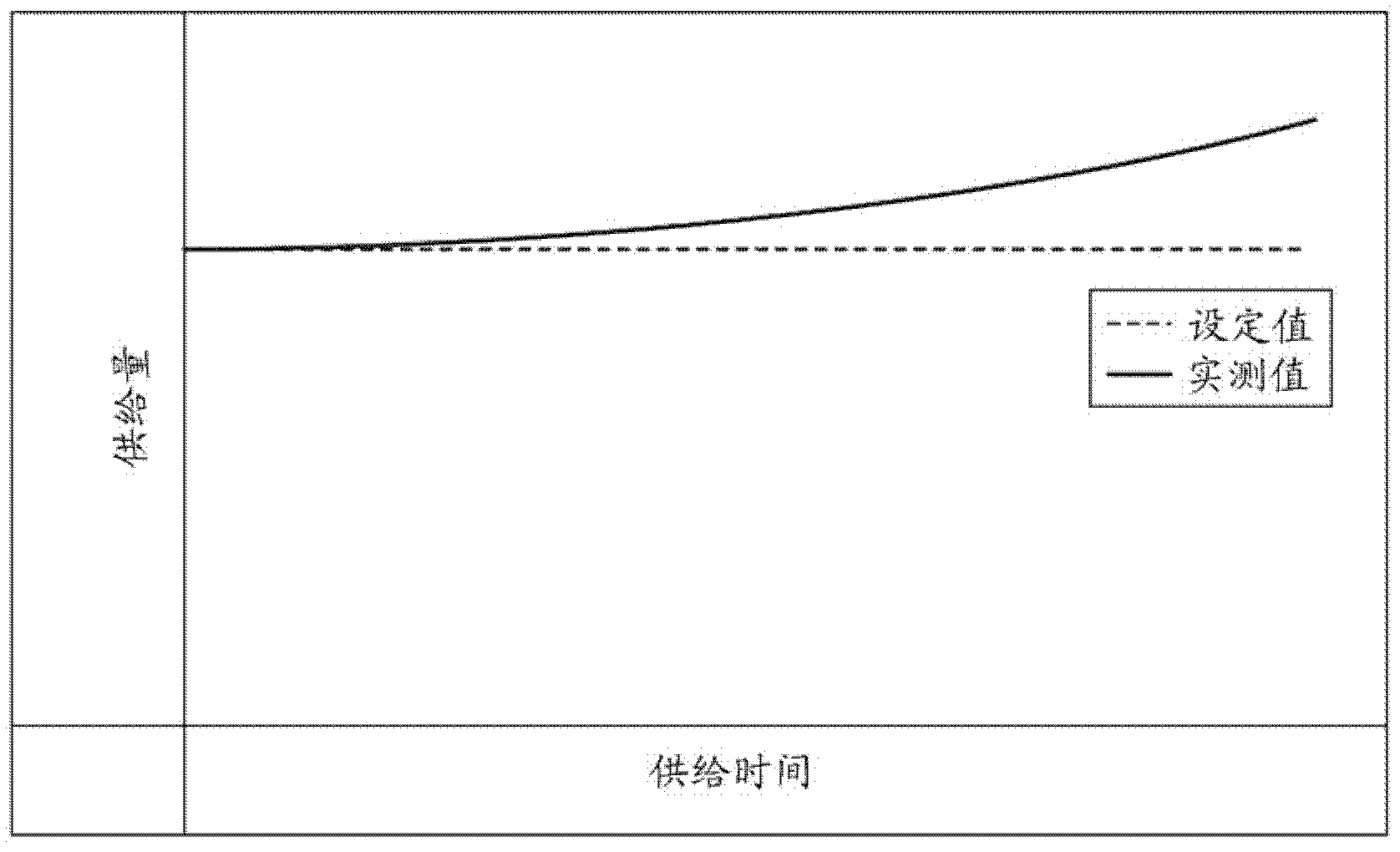

[0097] As shown in Table 2, in the buffer c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com