Arranging frame for sheet metal part machining

A technology for placing racks and sheet metal parts, applied in the field of sheet metal parts, can solve the problems of unsanitary products in the lower layer, and easy falling off of the racks when moving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

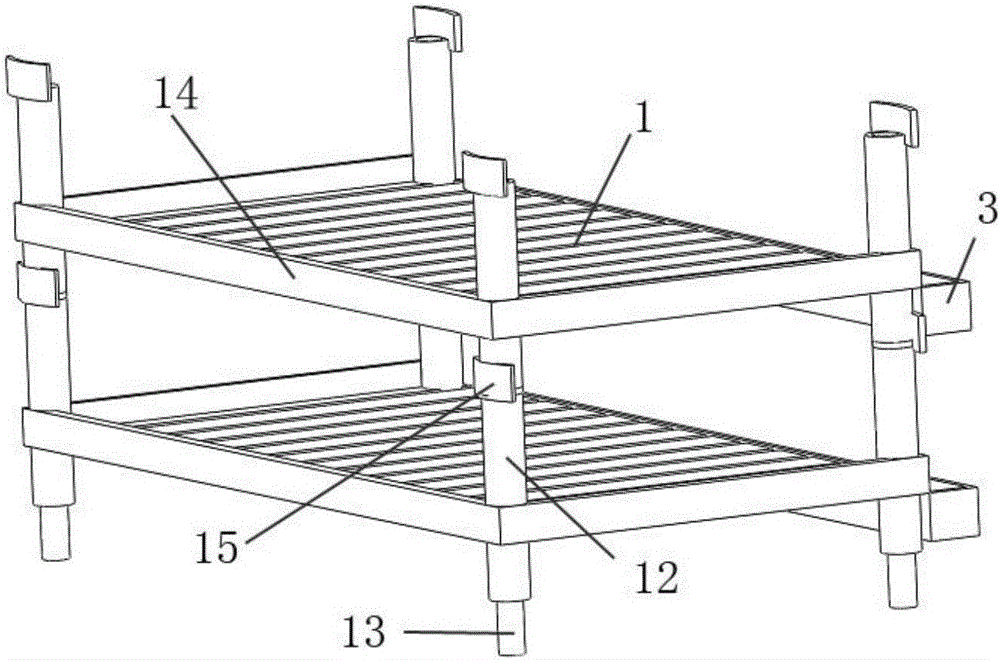

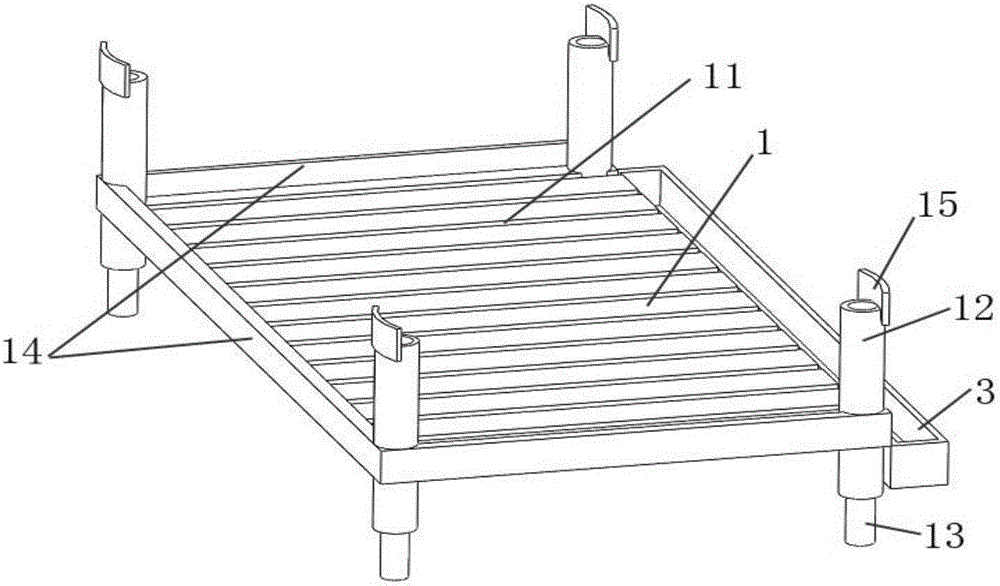

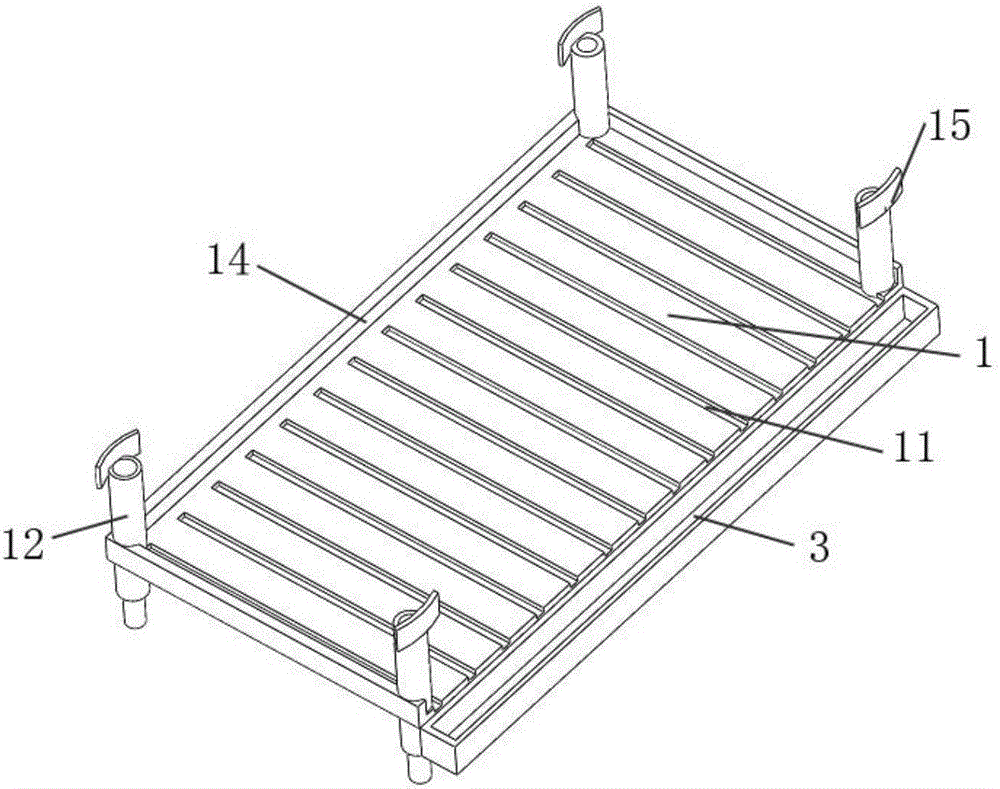

[0019] see figure 1 , a display rack for sheet metal parts processing, which consists of stacked two layers of racks; see figure 2 , image 3 , the shelf includes a laminate 1, a clamp 2 and a water tank 3;

[0020] see Figure 4 , the laminate 1 is a flat plate, and the top surface of the laminate 1 is concavely distributed with a strip-shaped hydrophobic groove 11 along the width direction, and the hydrophobic groove 11 is a chute, that is, a chute with one end high and the other end low; The four corners of the surface are all vertically provided with connecting pipes 12, and the pipe holes of the connecting pipes 12 are tapered holes. An anti-skid layer is provided on the upper surface; the edge of the top surface of the laminate 1 is provided with a circle of coaming 14, and the coaming 14 at the lower end of the hydrophobic groove 11 is open; the four corners on the bottom of the laminate 1 Every place is vertically provided with connecting rod 13, and connecting ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com