Production die special for automobile car door wiring harness sealing cover and injection molding machine

A technology for automobile doors and injection molding equipment, applied in the direction of coating, etc., can solve the problems of detachment, the connection between the plastic clip and the rubber sheath is not particularly stable, and the connection stability is weakened.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

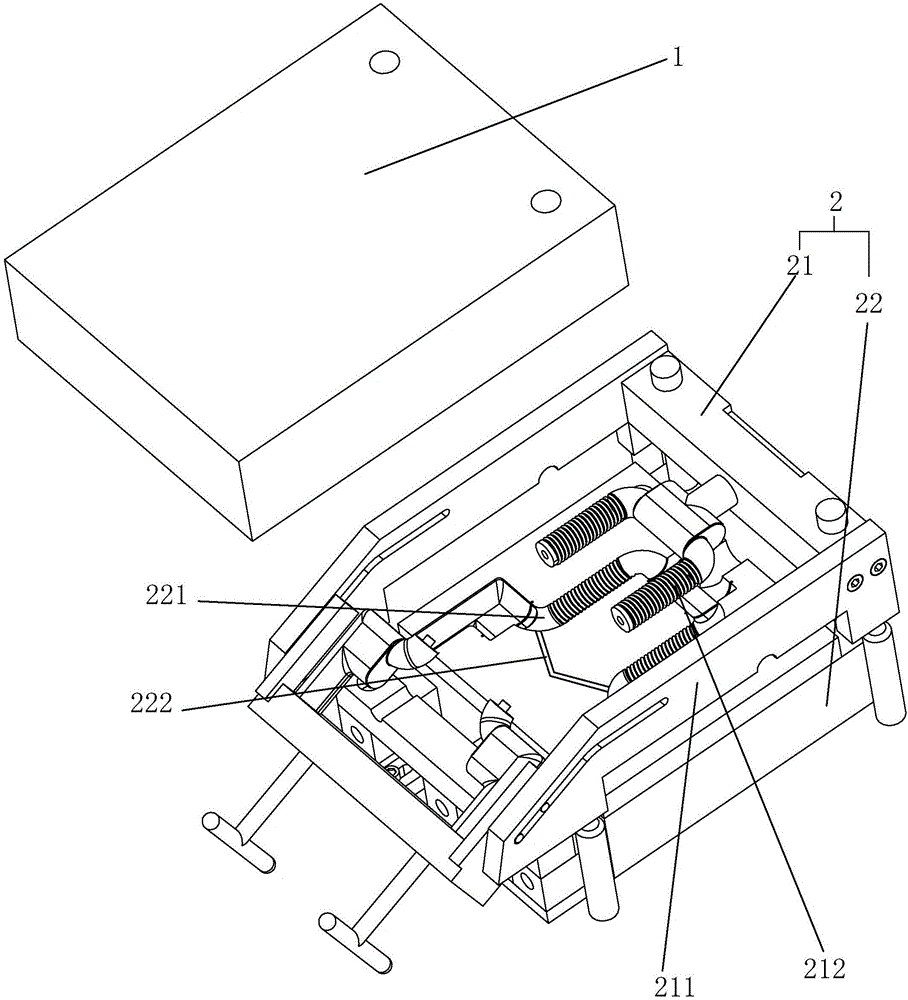

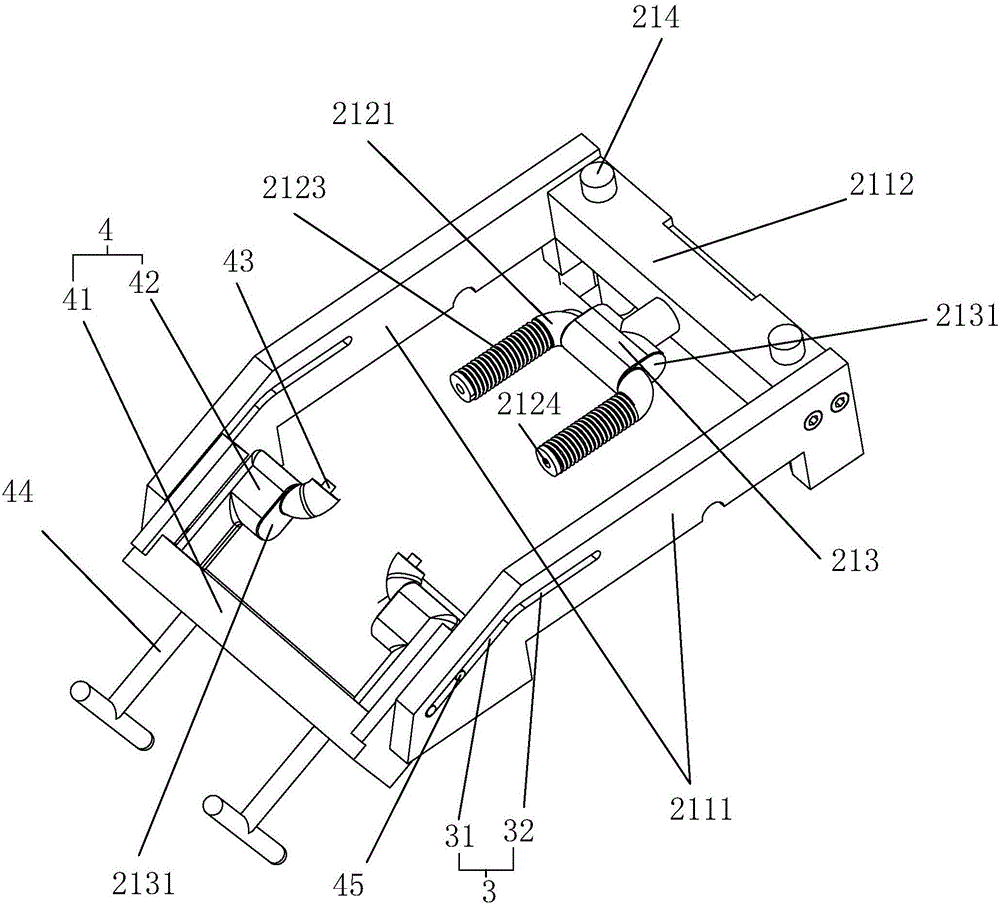

[0033] Embodiment one, such as Figure 1-Figure 2 As shown, a special production mold for the automobile door wiring harness sealing sleeve includes an upper mold 1 and a lower mold 2, and the lower mold 2 includes a fixed mold 22 and a movable mold 21, and the upper mold 1 and the fixed mold 22 are all provided with It is a concave mold, and the upper mold 1 and the fixed mold 22 are mainly used to form the outer surface of the harness sealing sleeve. A cavity 221 is formed between the upper mold 1 and the fixed mold 22, and the movable mold 21 is located between the upper mold 1 and the fixed mold. Between the molds 22, the movable mold 21 includes a mold base 211 and a punch 212 arranged on the mold base 211, the punch 212 is used to form the inner surface of the wire harness sealing sleeve, and the mold base 211 is sleeved on the outside of the fixed mold 22 , the mold base 211 moves toward or away from the fixed mold 22, and the punch 212 cooperates with the cavity 221 pr...

Embodiment 2

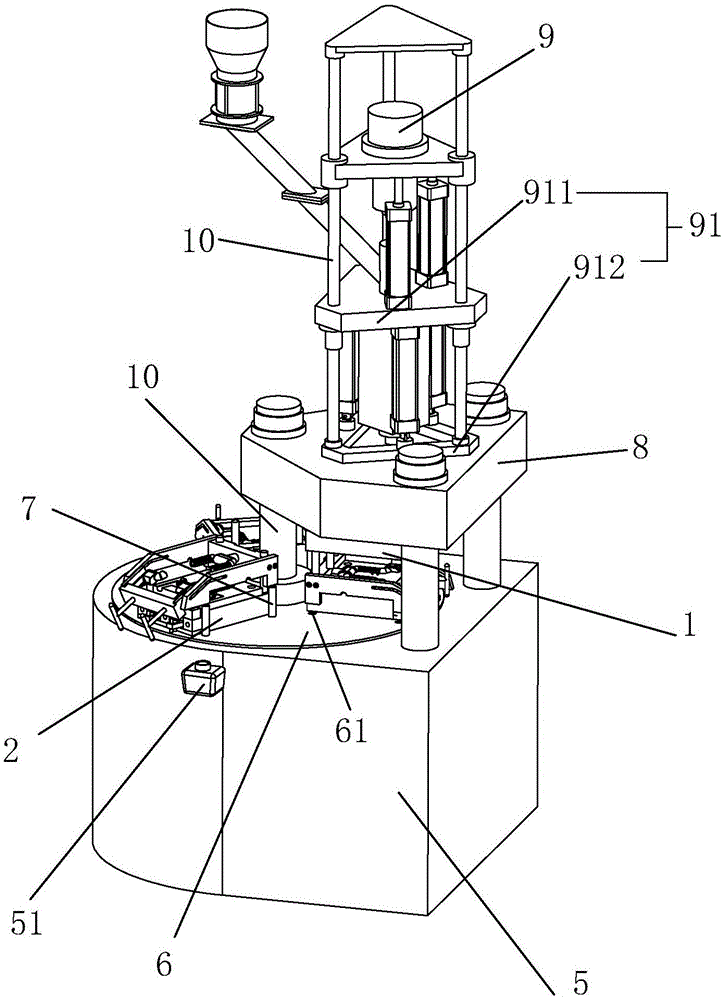

[0038] Embodiment two, such as image 3 As shown, a kind of injection molding equipment with the special production mold of the automobile door harness sealing sleeve described in Embodiment 1 includes a frame 5, and the frame 5 is simply a support platform, and the frame 5 A sinking installation area is provided on the upper surface of the upper surface, and a turntable 6 is embedded in the installation area. A drive unit for driving the turntable 6 to rotate is externally connected to the turntable 6. The drive unit specifically includes a control center and a The drive motor connected to the control center signal, the drive motor directly provides power for the rotation of the turntable 6, and the control center is used to control the start and stop of the drive motor. The control center can adopt more mature PLC, single-chip microcomputer or PC in the market.

[0039] Three lower dies 2 are fixedly arranged on the turntable 6, and the three lower dies 2 are evenly distribu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com