Field oil bag rapid deployment mechanism

A technology for deploying mechanisms and oil bags, which can be applied to motor vehicles, vehicles with elevated loading platforms, transport objects, etc., can solve the problem that the research on the opposite oil bag deployment method is not very active, and achieve the goal of conserving energy and reducing physical labor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

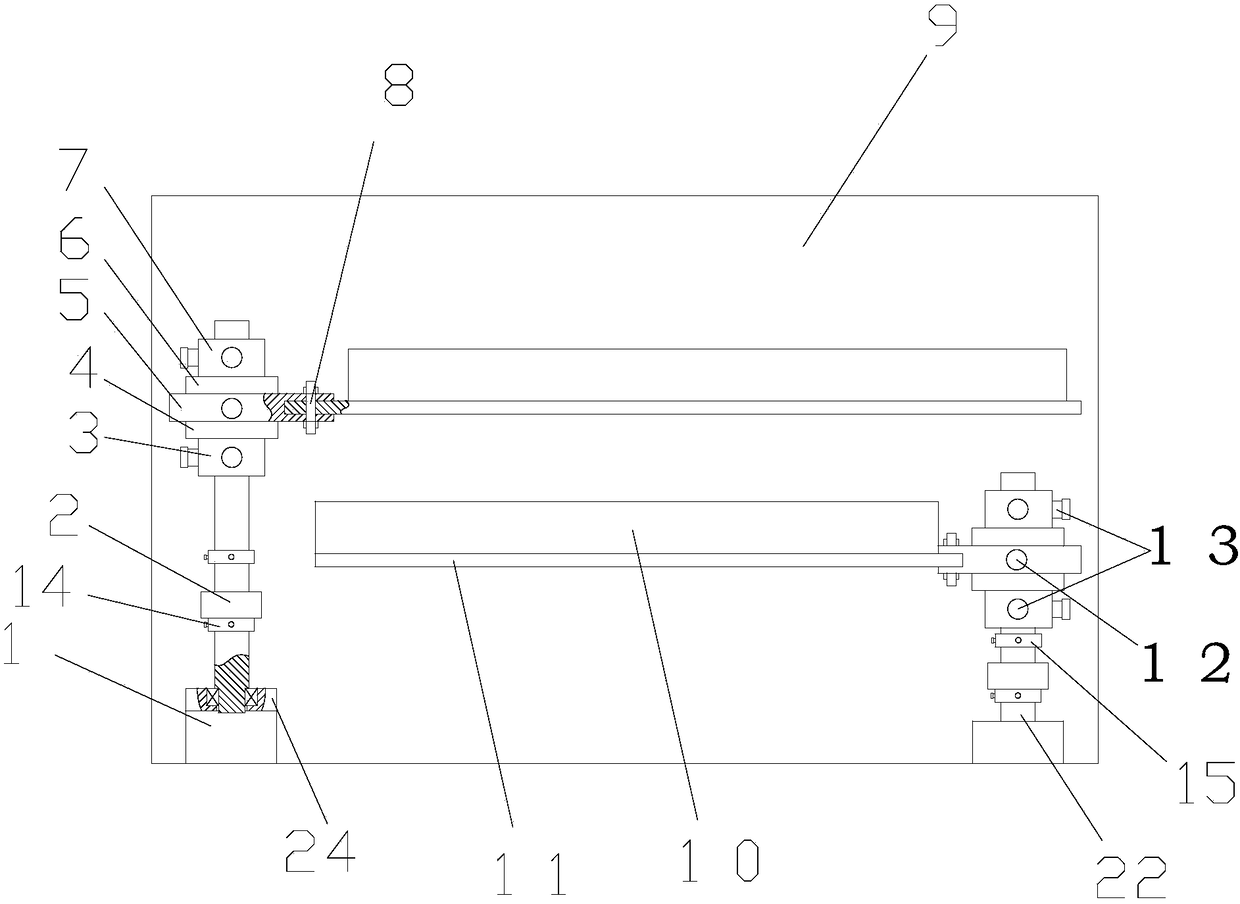

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

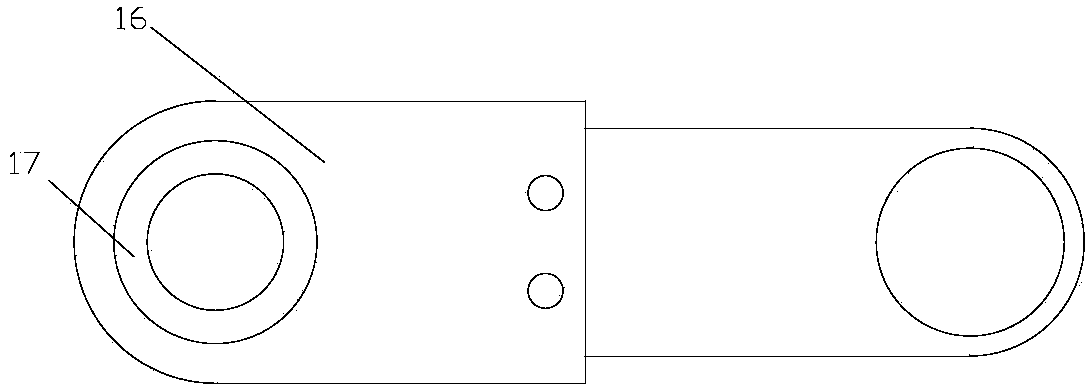

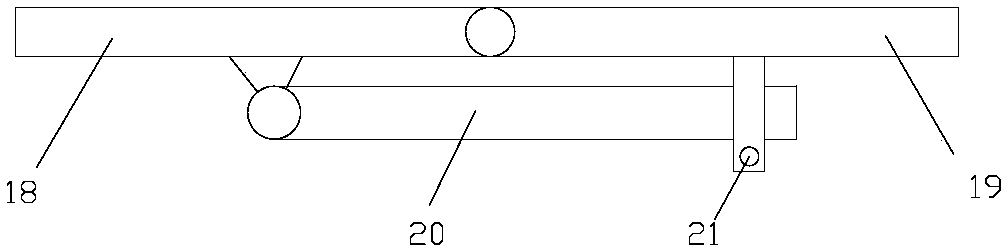

[0016] Such as Figure 1 to Figure 3 As shown, the field oil bag rapid expansion mechanism of the present invention comprises rotating motors ( figure 1 Only two motors are drawn in the figure, and two motors are omitted), the rotating motor is connected with the rotating shaft 22, and the rotating motor is connected with the rotating shaft 22 through a horizontal pin, and the rotating shaft 22 is sequentially covered with the lower fixed sleeve 3 and the lower The plane bearing 4 is equipped with a rotating plate 5 on the lower plane bearing 4, and the rotating plate 5 is locked on the rotating shaft by the first locking bolt 12. The upper plane bearing 6 and the upper fixing sleeve 7 are installed on the rotating plate 5. The upper fixed sleeve 7 and the lower fixed sleeve 3 are fixed on the rotating shaft by the second locking bolt 13, and a plurality of second loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com