Buffering combination for packaging soybean milk machine

A soymilk maker and buffer technology, applied in the field of packaging, can solve the problems of increased production costs, environmental threats, single form, etc., and achieve the effects of simple molding process and easy operation, improved safety and integrity, and simple and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below with reference to specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the embodiments are not intended to limit the present invention.

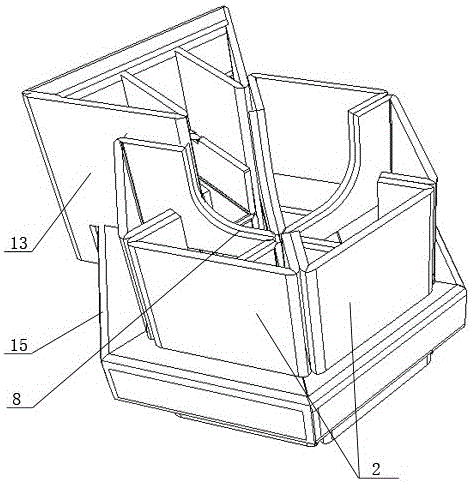

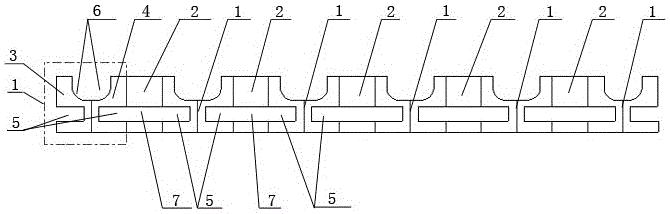

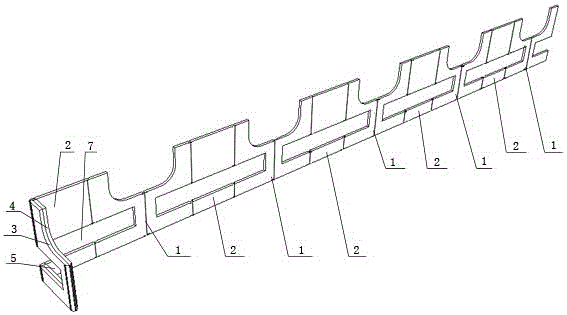

[0030] A buffer assembly for packaging a soymilk machine, such as figure 1 As shown, it includes a first buffer body and a second buffer body respectively folded from a piece of corrugated paper. The unfolded structure of the first buffer body, such as figure 2As shown in the figure, the first buffer body is formed by connecting six supporting plates 1 and five side plates 2 in sequence, that is, a side plate 2 is connected between two adjacent supporting plates 1, and both the head and the end are supporting plates 1. . Among them, the support plate 1 is formed by connecting the support plate I3 and the support plate II4, and the support plate I3 and the support plate II4 are symmetrically arranged with respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com