Coiled textile fabric storing rack

A technology of textile fabrics and storage racks, applied in the field of textile machinery, can solve problems such as hidden dangers and safety of support structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

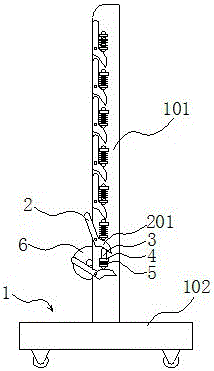

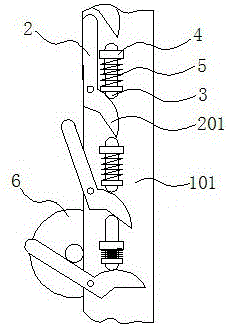

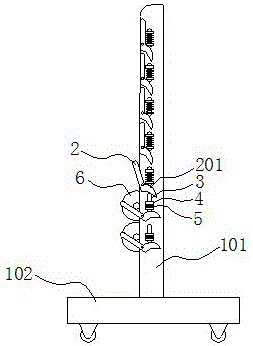

[0011] Now in conjunction with accompanying drawing, the present invention is described as follows.

[0012] Such as figure 1 , figure 2 As shown, the main body of the roll textile fabric storage rack is a cloth roll support frame, and the fabric roll support frame includes a support body 1, a support arm 2, and a spring expansion assembly. The support body 1 includes a bottom plate 102, and is vertically fixed on the bottom plate 102. There are two parallel support plates 101, the bottom of the bottom plate 102 is provided with rollers, and the outer surface of each support plate 101 is provided with hinged positions evenly spaced along the length direction of the support plates 101, and the hinged positions of the two support plates 101 are symmetrical. distributed. Each hinge position is hinged with a support arm 2 that is positioned and rotated relative to the support plate 101. When one end of the support arm 2 is unscrewed from the support plate 101, a V-shaped suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com