A gas leak detection system, method and device for a gas roaster

A detection device and gas leakage technology, which is applied in the direction of valve devices, instruments, alarms, etc., can solve the problems of lack of detection and control methods for gas ovens, and hidden dangers of personnel safety, so as to achieve high reliability and prevent safety accidents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] An embodiment of the present invention provides a gas leak detection system for a gas roaster, and the system includes: a gas detection device, a control device, and an execution device.

[0080] The gas detection device is used to detect the gas volume around the gas roaster, and output the gas volume information according to the gas volume.

[0081] Further, the gas detection device includes: a detector, the detector detects the gas around the gas roaster; an alarm, the alarm is connected to the detector, and receives the Detection results, and send alarm information according to the detection results.

[0082] Further, the gas detection device further includes: a concentration display connected to the detector to display the concentration detected by the detector.

[0083] Further, the detector is a detection transmitter.

[0084] Specifically, the detector is located above the accessories of the gas roaster, and monitors the gas concentration around the gas roaste...

Embodiment 2

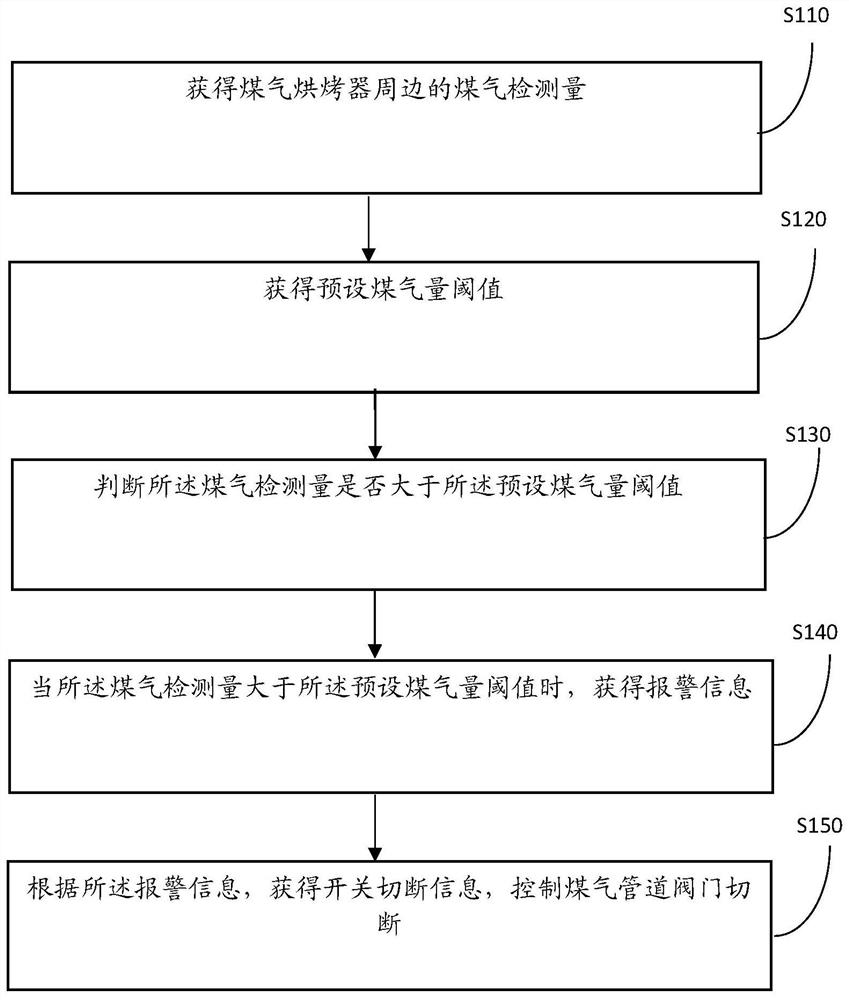

[0093] figure 1 It is a schematic flow chart of a gas leak detection method for a gas roaster in an embodiment of the present invention. Such as figure 1 As shown, the embodiment of the present invention provides a gas roaster gas leakage detection method, which is applied to the system described in Embodiment 1, and the method includes:

[0094] Step 110: Obtain the gas detection quantity around the gas roaster.

[0095] Step 120: Obtain a preset gas volume threshold.

[0096] Step 130: Judging whether the detected gas volume is greater than the preset gas volume threshold.

[0097] Step 140: Obtain alarm information when the detected gas volume is greater than the preset gas volume threshold.

[0098] Step 150: Obtain switch cut-off information according to the alarm information, and control the gas pipeline valve to cut off.

[0099]Specifically, when the roaster gas leaks, the gas alarm will detect the specific leakage amount, and when the set alarm value is exceeded,...

Embodiment 3

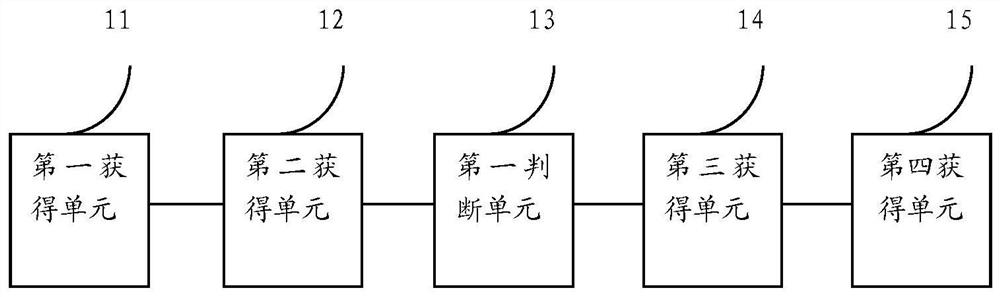

[0115] Based on the same inventive concept as the method for detecting gas leakage of a gas roaster in the foregoing embodiments, the present invention also provides a gas leakage detection device for a gas roaster, such as figure 2 As shown, the device includes:

[0116] A first obtaining unit 11, the first obtaining unit 11 is used to obtain the detected amount of gas around the gas grill;

[0117] A second obtaining unit 12, the second obtaining unit 12 is used to obtain a preset gas volume threshold;

[0118] A first judging unit 13, the first judging unit 13 is used to judge whether the gas detection amount is greater than the preset gas amount threshold;

[0119] A third obtaining unit 14, the third obtaining unit 14 is configured to obtain alarm information when the gas detection amount is greater than the preset gas amount threshold;

[0120] A fourth obtaining unit 15, the fourth obtaining unit 15 is configured to obtain switch cut-off information according to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com