A kind of in-situ reaction film-forming controlled-release fertilizer and its production method

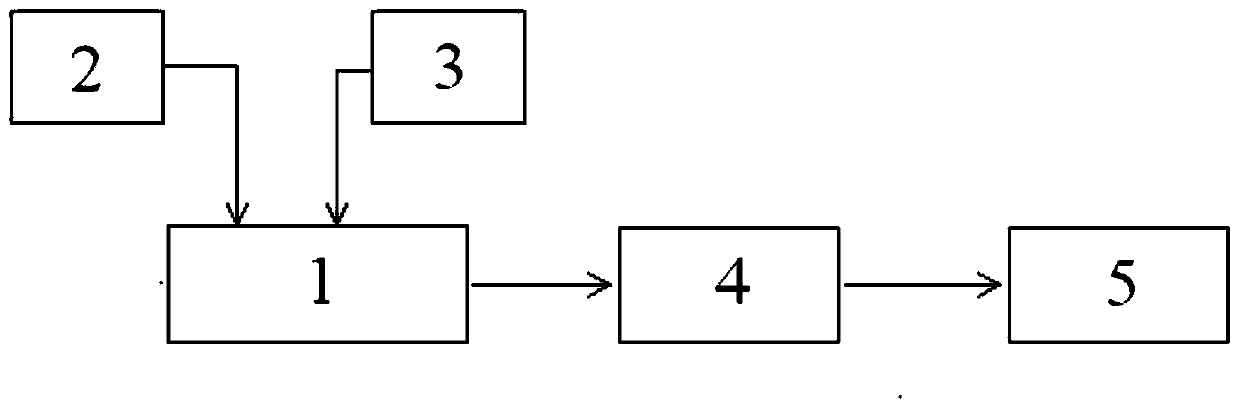

An in-situ reaction and controlled-release fertilizer technology, which is applied to fertilizer mixtures, layered/coated fertilizers, applications, etc., can solve the problems of unstable coating, loss of strength, and reduced controlled-release performance of fertilizers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] With 100g cornstarch, the liquefaction agent that is made up of 210g Polyethylene Glycol 400 and 90g glycerin, the concentrated sulfuric acid acidic catalyst of 8g98%, after mixing in the reactor that mechanical stirring and condensation tube are housed, be heated up to under constant stirring 160°C, constant temperature reaction for 120 minutes, and then rapid cooling to terminate the reaction to obtain starch polyol.

[0063] Firstly, urea granules (2-4 mm) are input into a heating drum with a lifting plate at a speed of 50 kg per minute, and the temperature of the drum is 100°C.

[0064] Then by 374g phthalic anhydride polyester polyol (purchased in Beijing Sikerui, trade mark is SKR-T5, relative molecular mass is 500); Coating solution II composed of paraffin wax at 60°C and 330 g of curing agent polymethylene polyphenyl polyisocyanate (the brand name is Bayer 44V20) are sprayed onto the surface of the rotating urea granule through the nozzle at the same time, and t...

Embodiment 2

[0068] Firstly, urea granules (2-4 mm) are input into a heating drum with a lifting plate at a speed of 50 kg per minute, and the temperature of the drum is 100°C.

[0069] Then the coating liquid I, 500g solidifying agent polymethylene polyphenyl polyphenylene polyol, 500g solidifying agent polymethylene polyphenyl polyphenylene polyol, 6g catalyst dibutyltin dilaurate, 24g auxiliary agent fusing point are formed by 60 ℃ of paraffins by 520g starch polyol prepared by the method provided in embodiment 1. Isocyanate (the trade mark is Bayer 44V20) is sprayed onto the surface of the rotating granular fertilizer by a nozzle simultaneously, and the coating layer formed accounts for 2% of the urea granule weight;

[0070] After about 3 minutes, 374g of phthalic anhydride polyester polyol (purchased from Beijing Sikerui, the brand name is SKR-T5, the relative molecular mass is 500); 4.4g catalyst dibutyltin dilaurate, 4.4g catalyst triethanolamine, 33.8g additive Coating solution II...

Embodiment 3

[0073] With 100g corn stalk powder, the liquefaction agent that is made up of 250g macrogol 400 and 50g glycerin, the concentrated sulfuric acid catalyst of 9g98%, after mixing uniformly in the reactor that mechanical stirring and condenser tube are housed, be heated up to under constant stirring 160° C., constant temperature reaction for 120 minutes, and then rapid cooling to terminate the reaction to obtain straw polyol.

[0074] Firstly, the Sacofu compound fertilizer (2-4mm, N-P-K: 15-15-15) is input into the heating drum with a lifting board at a speed of 50kg per minute, and the temperature of the drum is 70°C.

[0075] Then by 288g polyether polyol TAE470 (purchased from Tianjin Petrochemical, relative molecular mass is 470), 8.5g catalyst stannous octoate, 75.6g soybean oil polyol (purchased from U.S. USSC company, trade mark is Soyoyl R137, relative molecular mass is 530), coating solution II, 396g solidifying agent polymethylene polyphenyl polyisocyanate that 17.1g a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com