Needle selection knitting system for glove machine

A technology of weaving system and glove machine, which is applied in the field of glove machine, can solve the problems of high difficulty, various components, high difficulty in production, installation and maintenance, and achieve the effects of improving production efficiency, rich diversity, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

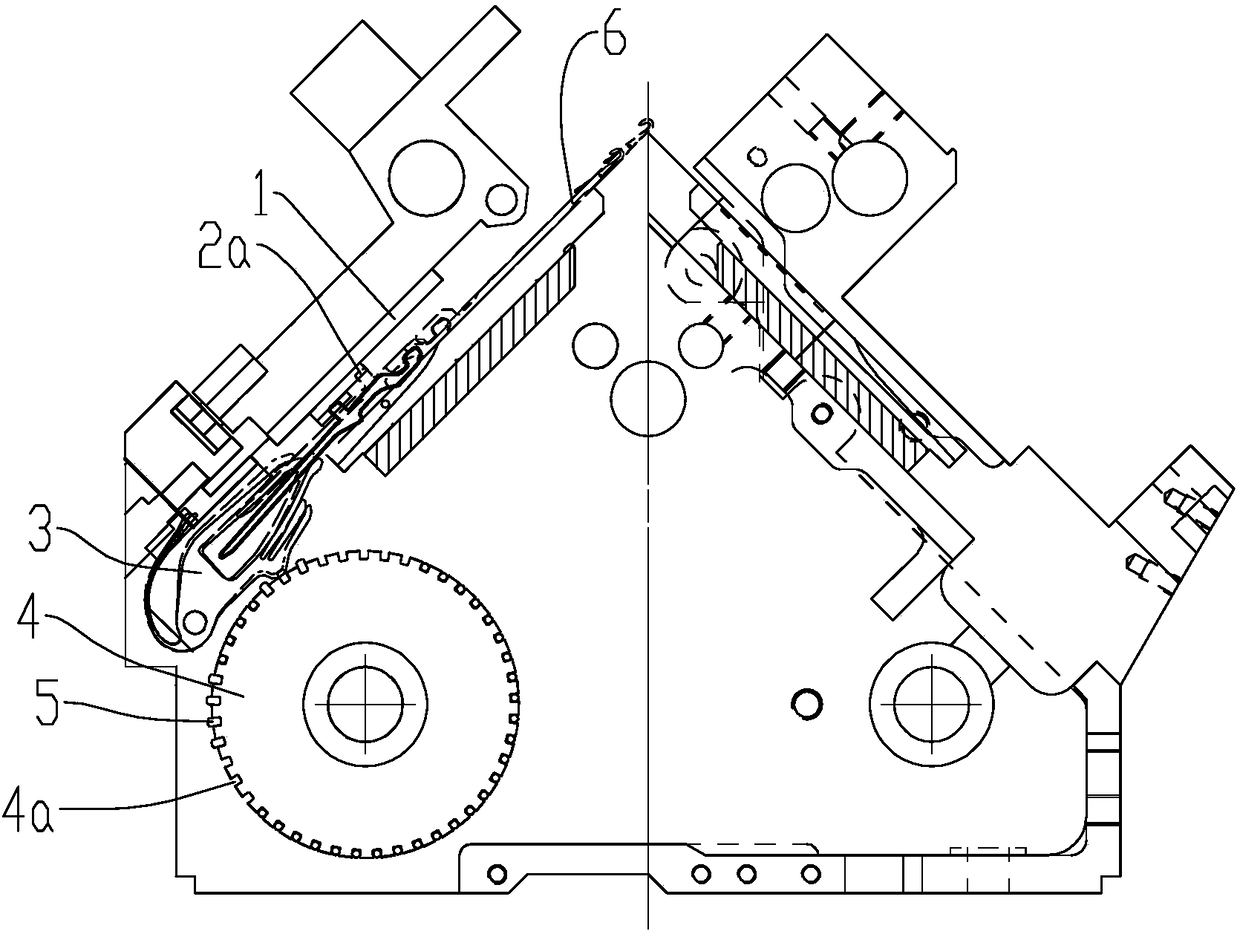

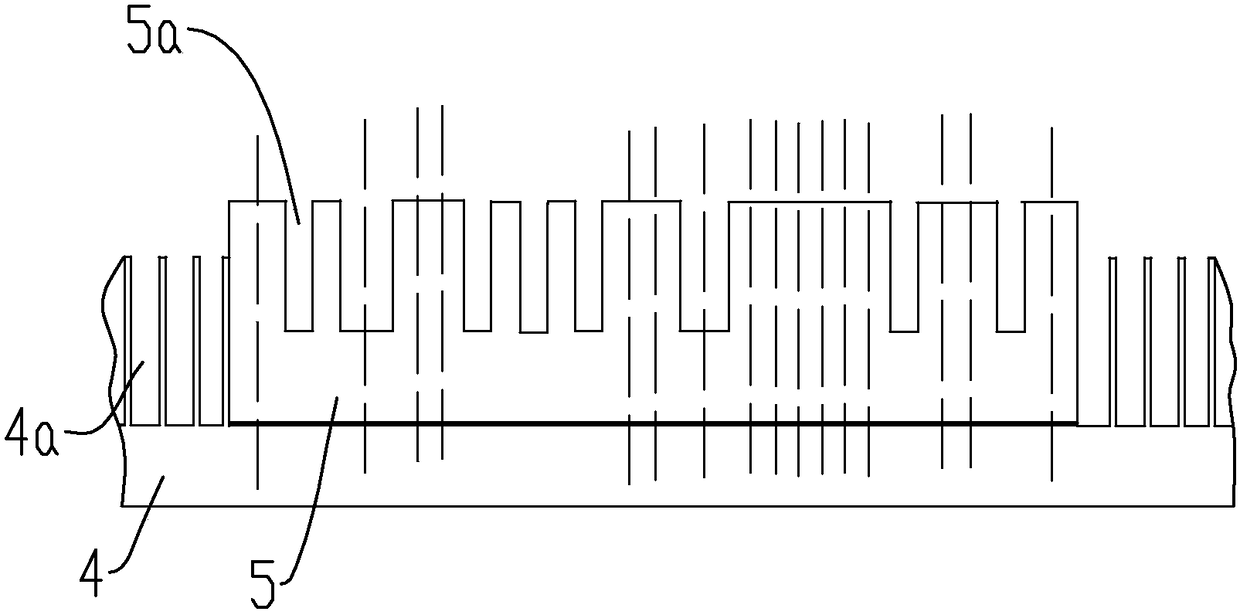

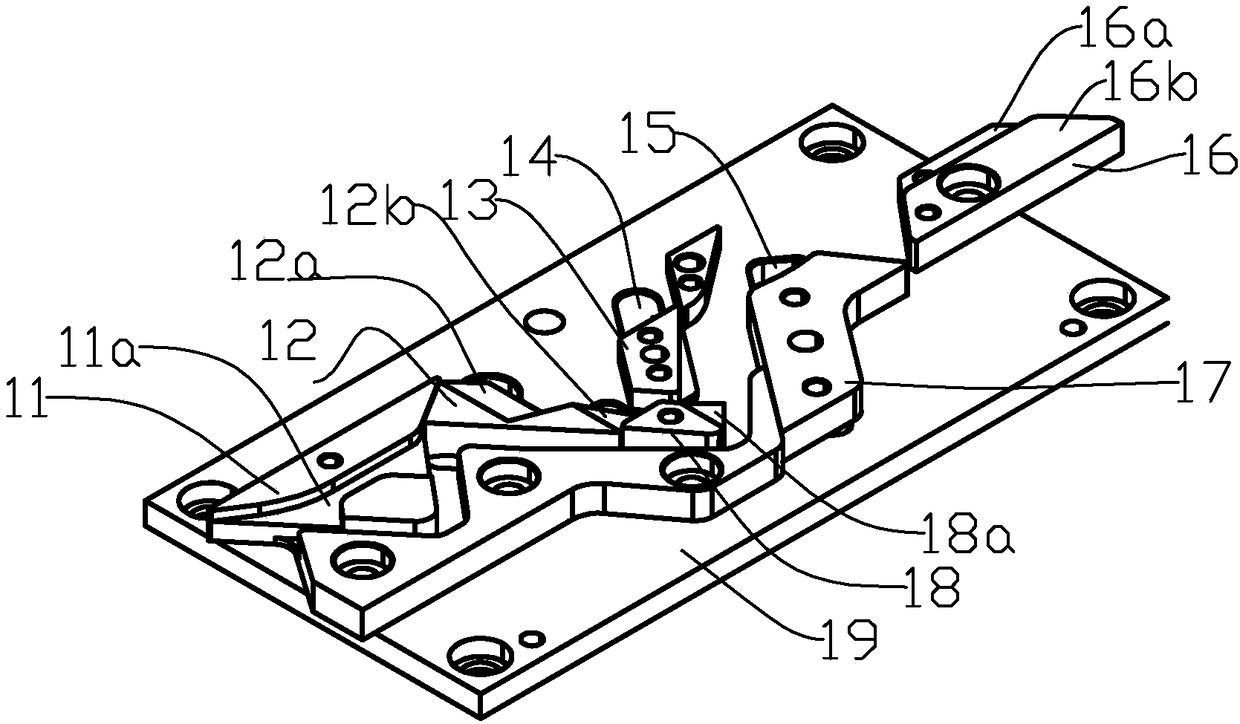

[0026] Such as figure 1 As shown, this embodiment includes a needle selection cylinder 4, a needle selection bird piece 3, a needle jack 2, knitting needles 6 and a triangular plate 1, and the surface of the needle selection cylinder 4 is provided with a number of horizontally and vertically arranged and evenly distributed grooves. Some braiding pins 5 are embedded horizontally according to the braiding needs. The needle selection cylinder 4 is horizontally provided with needle selection birds 3 corresponding to the number of its transverse grooves. Each needle selection bird piece 3 is provided with a protruding end and a supporting end, and the protruding end is set in cooperation with the groove. Each needle selector bird 3 has a needle jack 2 arranged in cooperation with its supporting end, and each needle jack 2 corresponds to a knitting needle 6 . The knitting needles 6 are also horizontally arranged, one end of which is matched with the needle jack 2 for needle select...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com