Device for lifting inner steel barrel of chimney

A steel inner tube and chimney technology, which is applied in the field of chimney steel inner tube lifting devices, can solve the problems of reducing the safety of the steel inner tube and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

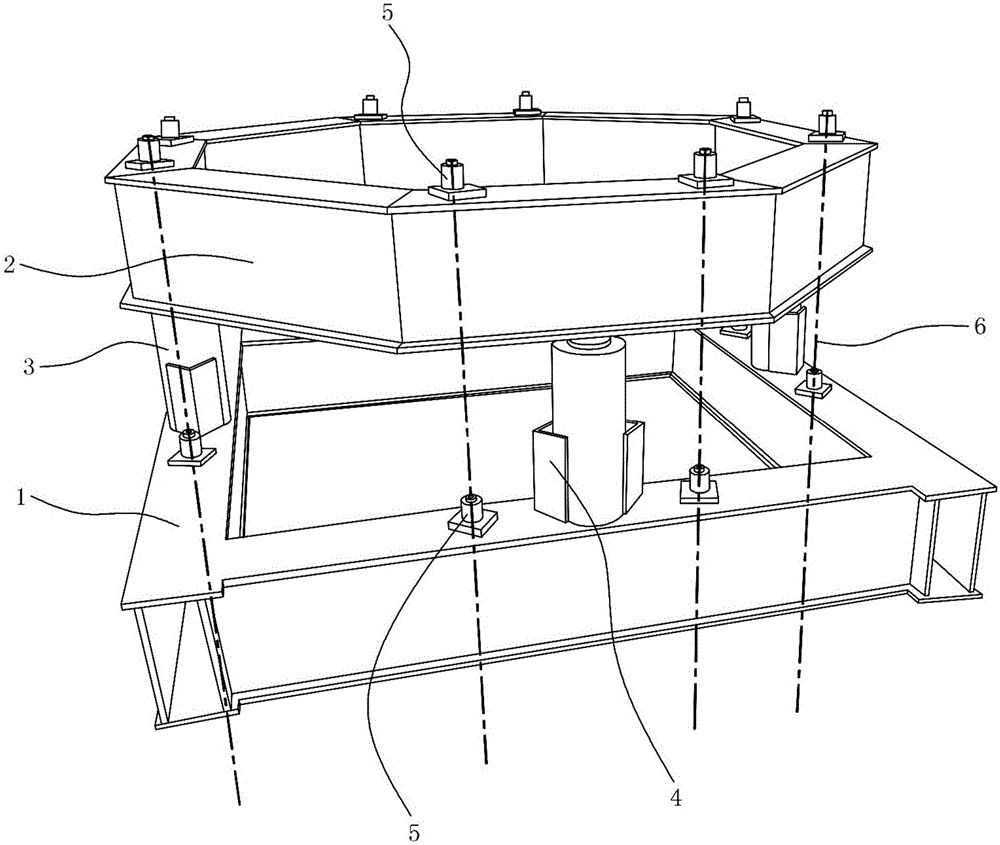

[0013] Such as figure 1 As shown, the hoisting device of the chimney steel inner cylinder is composed of a base 1, a lifting seat 2, a jack 3, an anchor 5, a guard plate 4 and a wire rope 6.

[0014] Four jacks 3 are arranged between the base 1 and the lifting seat 2, and the tops of the jacks 3 support the lifting seat 2. The base 1 is a regular quadrilateral frame, the lifting base 2 is a regular octagonal frame, the inscribed circles of the base 1 and the lifting base 2 are the same, and the four cutting edges of the lifting base 2 coincide with the four cutting edges of the base 1 . The jacks 3 are evenly distributed in the middle of the four overlapping trimmings of the base 1 and the lifting seat 2 . Two hoisting holes are provided on each overlapping trimming edge, and anchorages 5 are installed at the hoisting holes, and steel wire ropes 6 are threaded through the anchorages 5. The cross-sectional structures of the base 1 and the lifting base 2 are both hollow struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com