Water pan of medium-low temperature machine

A water-receiving pan and low-temperature technology, which is applied in the field of refrigeration equipment, can solve problems such as water and scale accumulation in the water-collecting pan, and achieve the effects of improving heat exchange capacity, improving efficiency, and preventing water blowing and scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

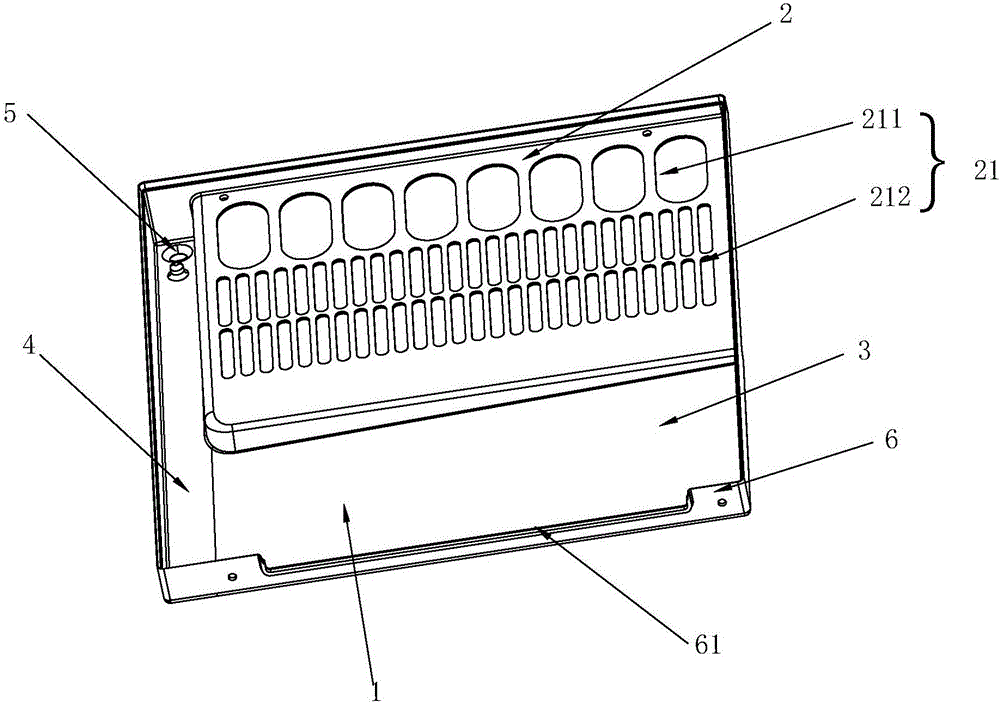

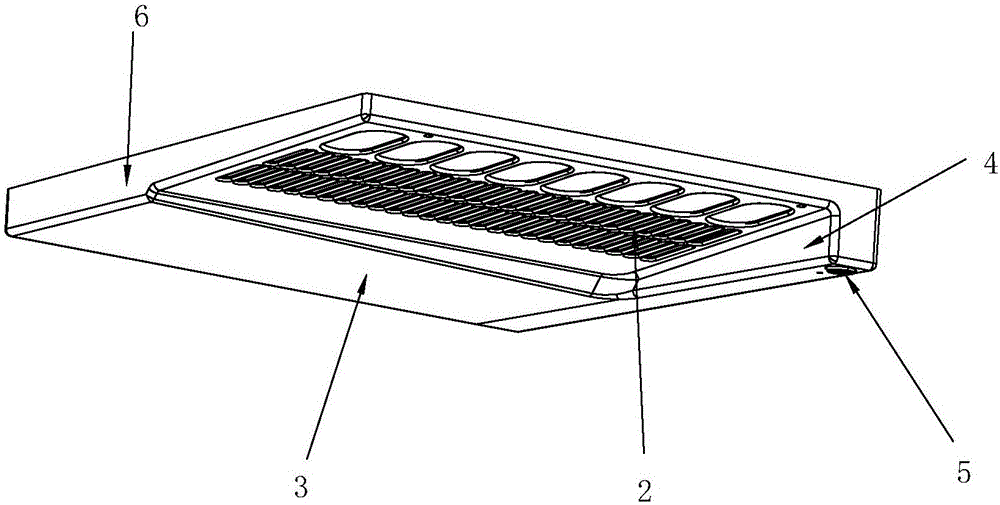

[0018] see figure 1 and figure 2 , a water receiving tray of a medium and low temperature machine according to the present invention includes a water receiving tray body, and the water receiving tray body 1 is square. The water tray body 1 is made by one-piece stamping, which reduces the difficulty of processing. One side of the water receiving tray body 1 is inclined upwards to provide a steam condensing pan 2 that facilitates air circulation, and a plurality of return air holes 21 are opened on the condensing pan 2, and the return air holes 21 include large return air holes 211 and The small return air hole 212, the large return air hole 211 is located at the bottom of the condensing pan 2, the small return air hole 212 is located at the bottom of the condensing pan 2, and the return air holes 21 with different apertures can be used for air backflow to pass through There are different speeds in the condensing pan, which increases the air exchange efficiency law on the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com