Self-adaptive type extensometer with multiple deformation modes

An extensometer and adaptive technology, applied in the field of multi-deformation mode adaptive extensometers, to achieve the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

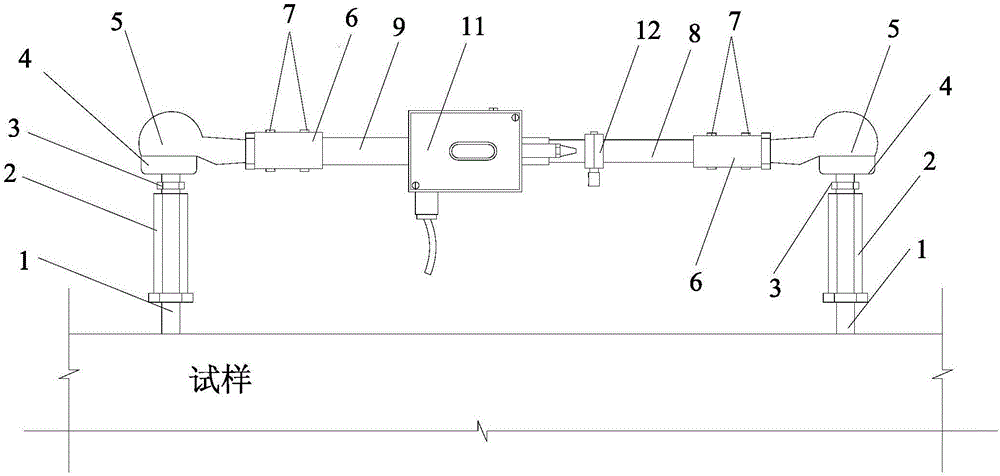

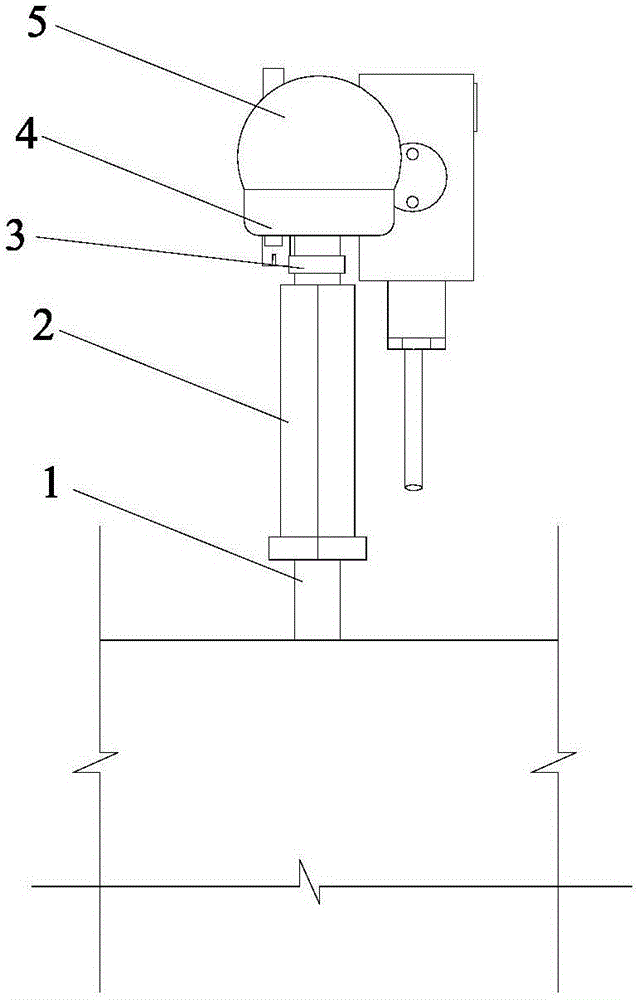

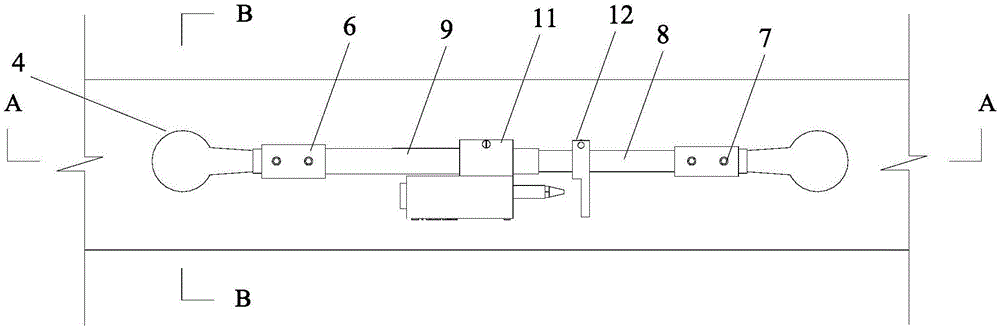

[0026] see Figure 1 to Figure 5 As shown, a multi-deformation mode adaptive extensometer includes:

[0027] Two positioning bolts 1, two two-way connecting nuts 2, two universal joint components, two connecting bolts 10, two connecting sleeves 6, telescopic steel pipe groups and extensometers; the universal joint components include ball joint connecting bolts 3 and ball joints Hinged top cap 5; the telescopic steel pipe group includes the first telescopic steel pipe 8 and the second telescopic steel pipe 9; the extensometer includes a test sensing box 11 and a test baffle plate 12; the positioning bolt 1 is not threaded One end of which is fixed on the sample, the threaded end of the positioning bolt 1 is connected to one end of the two-way connection nut 2, and the other end of the two-way connection nut 2 is connected to the threaded end of the spherical hinge connection bolt 3, so One end of the ball hinge connecting bolt 3 without thread is hinged with one end of the bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com