Multi-scale direct load control method of electric water heater group

An electric water heater and load control technology, applied in the directions of fluid heaters, circuit devices, AC network circuits, etc., can solve problems such as not being a reasonable solution, and achieve the effects of reducing load burden, improving stability, and realizing load transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with accompanying drawings and examples.

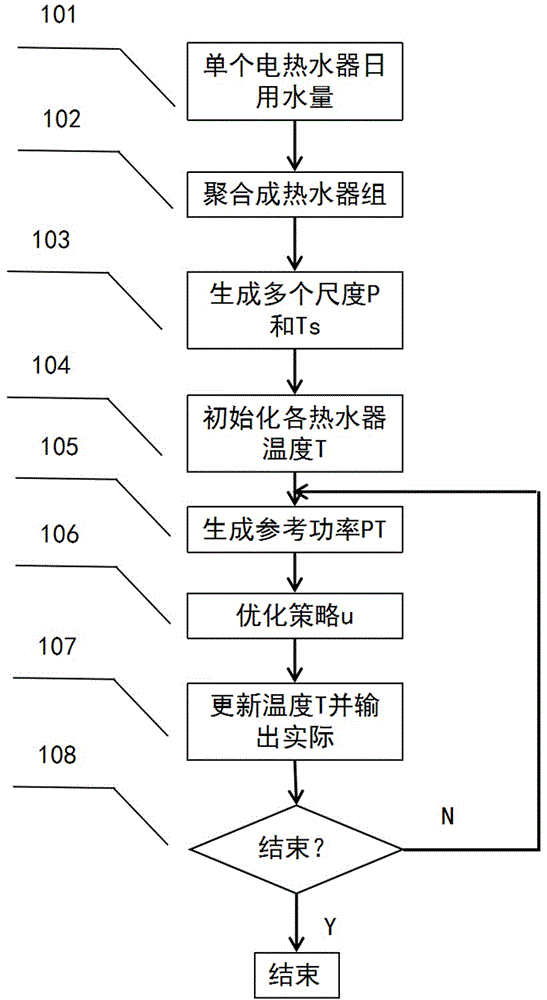

[0025] refer to figure 1 , this method includes the following steps:

[0026] (1) First execute step 101. According to the household daily load curve statistics, the daily water consumption of a single water heater base=[6 43 3 1 5 13 48 33 36 27 26 23 23 24 15 17 16 24 32 26 17 23 24];

[0027] (2) Execute step 102, divide 1000 water heaters (total power 3600kw) into 10 groups according to power, capacity, upper and lower limits of temperature and daily water consumption, which are [55°C, 50°C, 120L, 3000W, 2 / 3*base], [55°C, 50°C,160L, 3000W, base],[55°C, 50°C, 200L, 3000W, 1.2*base], [55°C, 50°C, 320L, 3000W, 1.5*base], [55°C , 50°C, 320L, 6000W, 1.5*base],[50°C,45°C, 120L,3000W, 2 / 3*base], [50°C, 45°C, 160L, 3000W, base], [50°C, 45°C, 200L, 3000W,1.2*base], [50°C, 45°C, 320L, 3000W, 1.5*base], [50° C, 45°C, 320L, 6000W, 1.5*base];

[0028] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com