A fdm type 3D printing nozzle and method based on the principle of color mixing and dyeing

A 3D printing and nozzle technology, applied in the field of 3D printing, can solve the problem of not full-color 3D printing, and achieve the effect of vivid color, simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

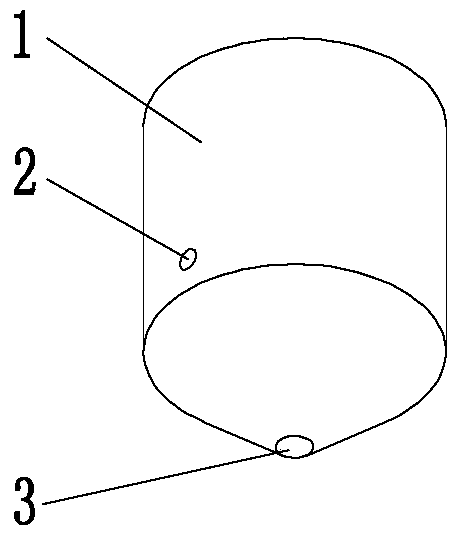

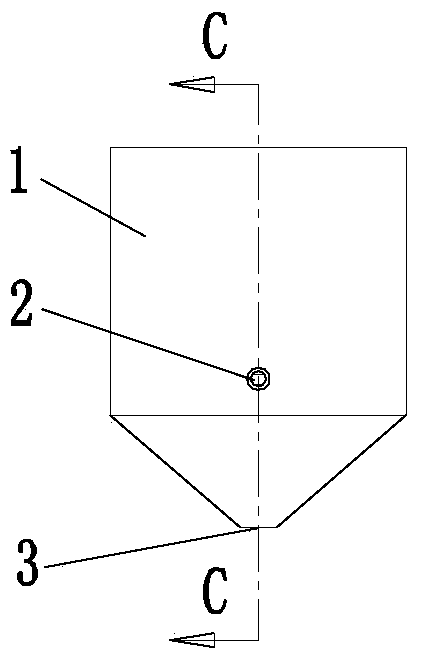

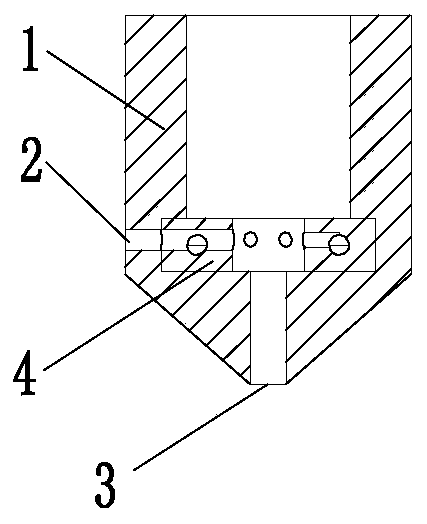

[0031] Such as Figure 1 to Figure 9 As shown, a FDM type 3D printing nozzle based on the principle of color mixing and dyeing includes an integrated heating chamber 1 and a tapered nozzle 3. The heating chamber 1 is provided with an annular dyeing ring 4 and a nozzle for melting silk. Heating device, the center of the annular dyeing ring 4 is provided with a circular feeding port 44 for printing raw materials to pass through, and a closed annular channel 43 is provided in the entity of the dyeing ring 4 with the symmetrical center of the dyeing ring 4 as the center, The outer circular wall of the dyeing ring 4 is radially penetrated with a dyeing ring ink inlet 41 communicating with the annular passage 43, and the inner circular wall of the dyeing ring 4 is evenly provided with several communicating annular passages radially. 43 and the ink guide tube 42 of the feed port 44, the outer peripheral wall of the heating chamber 1 is also provided with the ink inlet 2 of the nozzle...

Embodiment 2

[0035] An FDM type 3D printing method based on the principle of color mixing and dyeing using the nozzle as described, comprising steps:

[0036] 1) The color recognition system uses slicing software to slice and layer the 3D model and obtain the position information and color information of each layer. The color information is stored in the model database corresponding to the slicing information in 24-bit RGB codes;

[0037] 2) Utilize the RGB code data to drive the movement of the color picking device of the external color mixer, take cyan, magenta, yellow, and black dyes from each primary color box 6 in proportion and send them to the mixing chamber 9 through the color picking pipeline 10 for color matching, After the toning is completed, it is transported to the dyeing ring 4 through the delivery pipeline 11;

[0038] 3) Extrude the printing filament according to the data information of model slicing and color picking, and control the X, Y, Z motors to drive the printing n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com