Belt breakage catching device of belt type conveyor

A broken belt capture device and belt conveyor technology, which is applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve the problem of sudden large capture force, easy damage to the belt, machine crash and death, etc. problems, to achieve the effect of convenient test and maintenance, low equipment cost, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

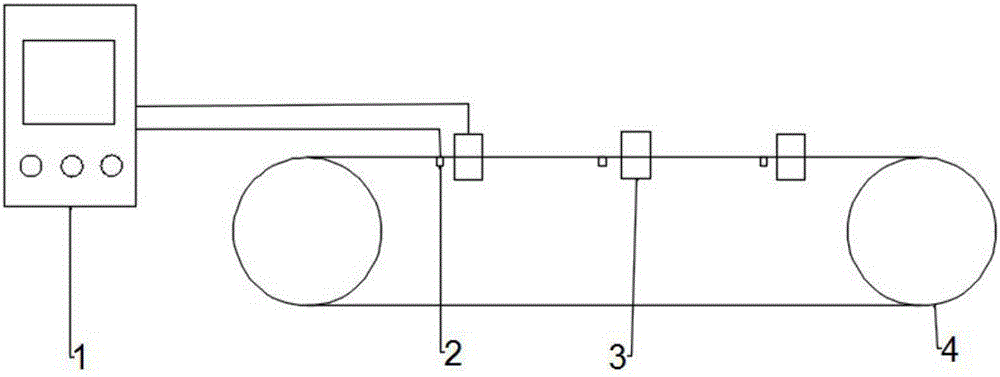

[0018] Depend on figure 1 As can be seen, the device of the present invention comprises a control host (1), a broken belt detection device (2) and a plurality of catching sub-stations (3), the control host and the catching sub-stations are connected by communication lines, and the control host is also connected with the catching sub-stations. The broken belt detection devices are connected, and the arresting substations are evenly arranged on the belt conveyor (4) at a certain interval. Each arresting substation is divided into a control unit and a mechanical execution unit, and the left and right sides of the mechanical execution unit are arranged symmetrically. , each side is composed of an upper catch mechanism and a lower catch mechanism.

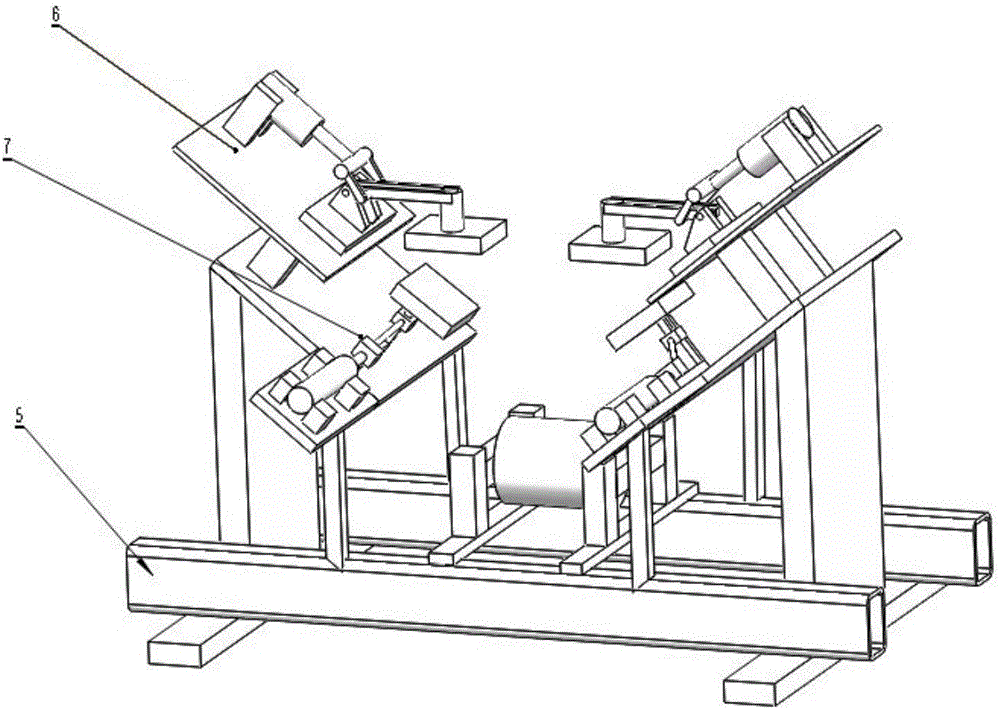

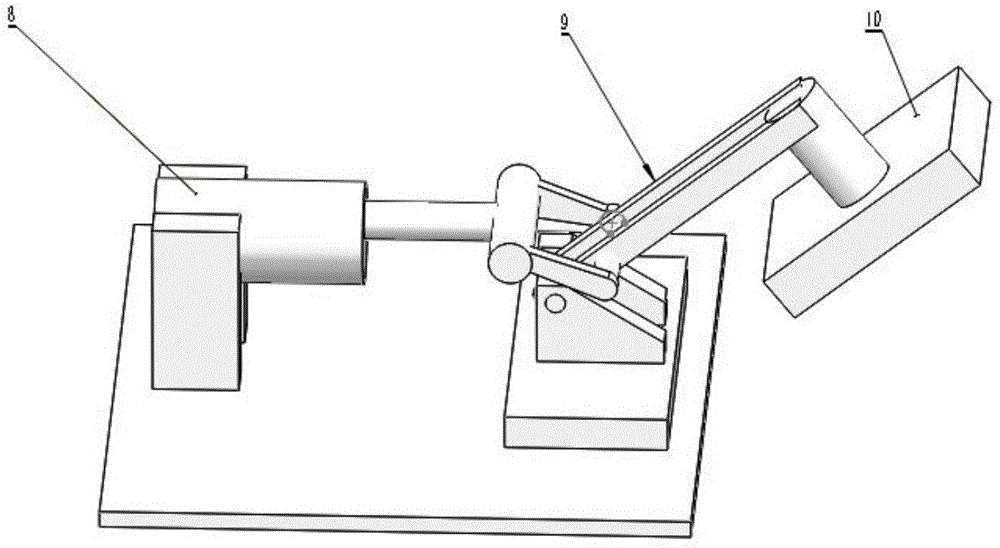

[0019] Depend on figure 2 , image 3 , Figure 4 It can be seen that the broken belt arresting device of the belt conveyor comprises a frame (5), an upper arresting mechanism (6) and a lower arresting mechanism (7). The upper catch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com