Continuous casting type large-wall-thickness hot-rolled steel plate for deep sea pipelines and production method thereof

A hot-rolled steel plate and continuous casting billet technology, applied in the field of pipeline steel, can solve the problems of low yield ratio and high uniform elongation, and achieve the effect of low yield ratio and high uniform elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

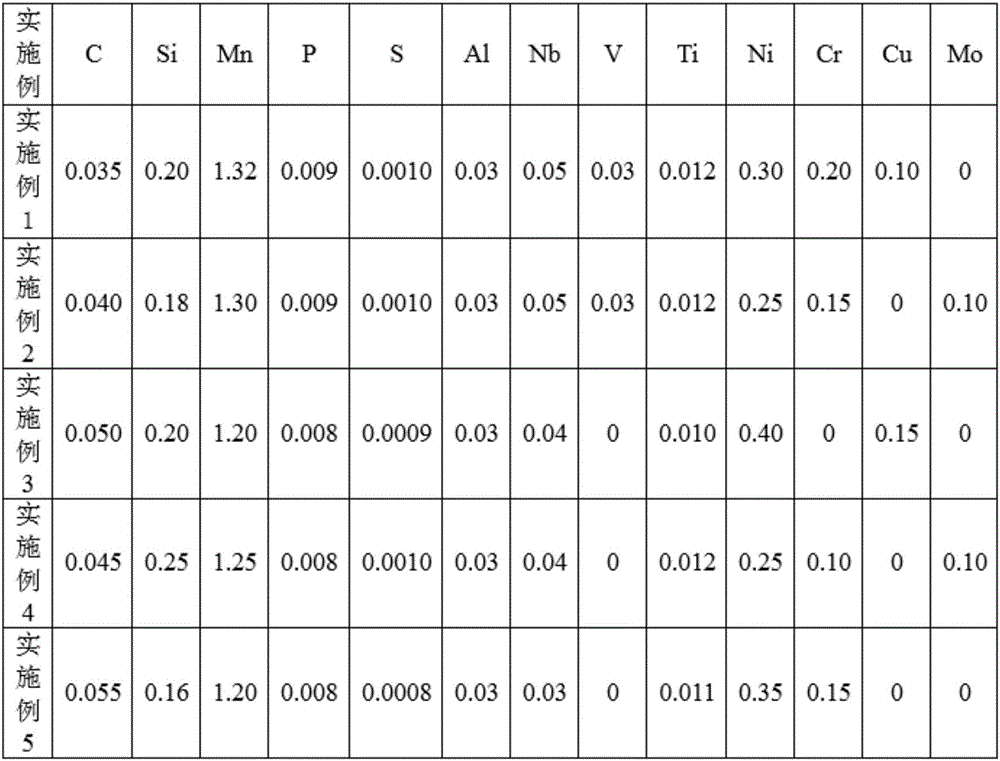

[0028] 1. The chemical composition of the hot-rolled steel plate for deep-sea pipelines in the embodiment is shown in Table 1 below:

[0029] Table 1 steel plate chemical composition (wt%)

[0030]

[0031] The above examples are all chemical composition weight percentages, and the balance is Fe and unavoidable impurity elements.

[0032] Two, embodiment technological system is as shown in table 2 below:

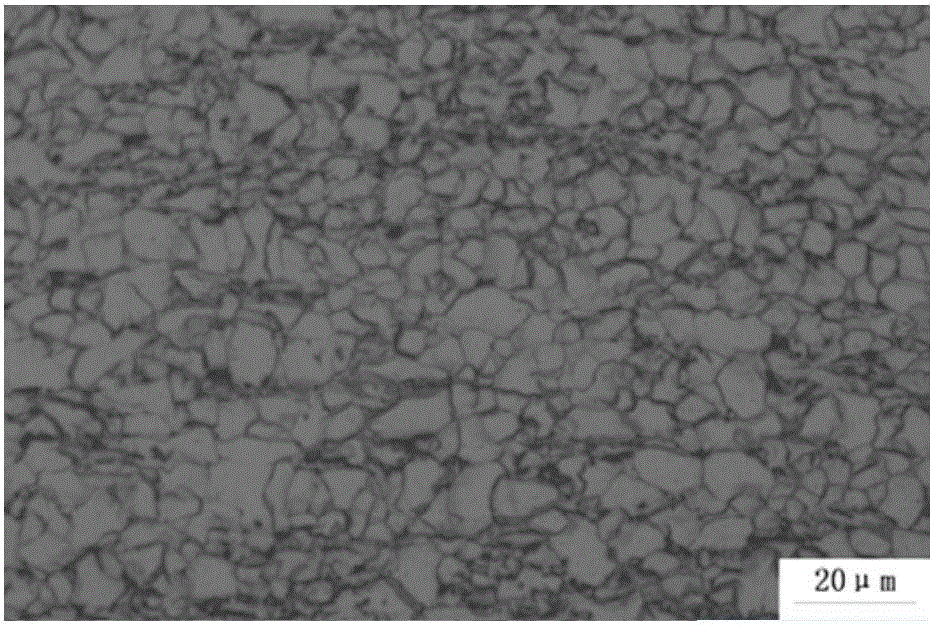

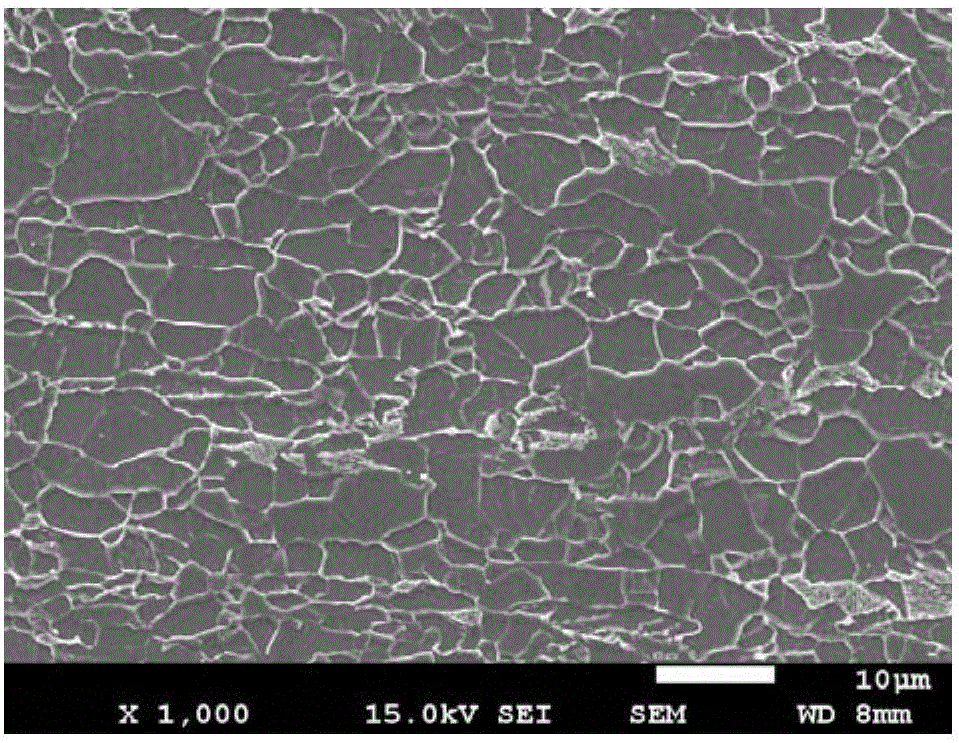

[0033] In the embodiment, the hot-rolled steel plate for the deep-sea pipeline is first continuously cast into a 400mm thick steel slab, and then undergoes reheating, two-stage controlled rolling, controlled cooling, and stacking slow cooling to obtain a fine and uniform polygonal ferrite structure, and the thickness of the finished steel plate is 41-48mm.

[0034]Table 2 embodiment technological system

[0035]

[0036] Three, embodiment mechanical properties are as shown in table 3 below:

[0037] The mechanical properties of the hot-rolled steel plates for deep-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com